Lifting stand column

A technology for lifting columns and casings, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of troublesome assembly, high cost of lifting columns, and high costs of non-circular tubes, and achieves cost reduction requirements and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

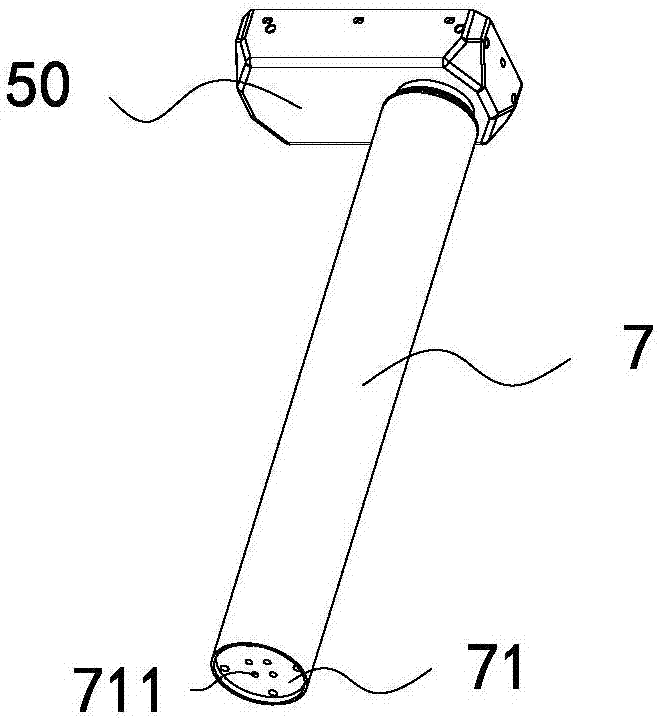

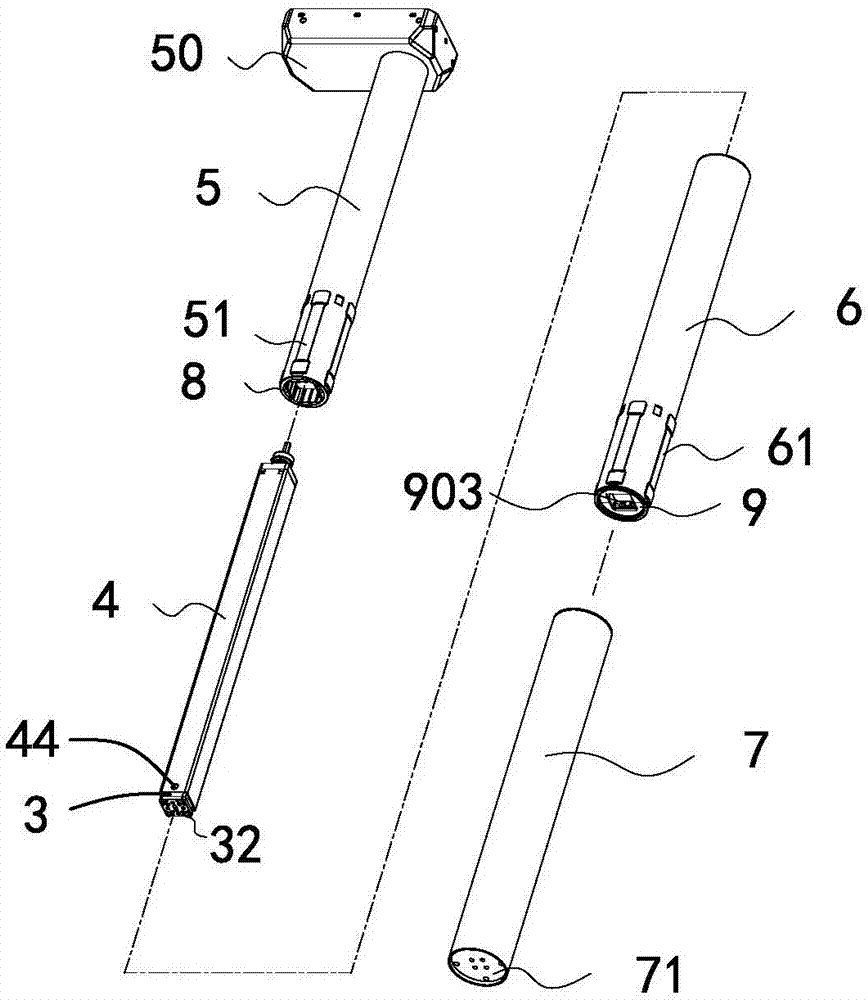

[0041] Such as Figure 1 to Figure 6 As shown, the present embodiment is a lifting column, which includes an inner tube 5, a middle tube 6, and an outer tube 7 that are sequentially set from the inside to the outside, wherein the upper end of the inner tube 5 is fixedly connected to the bottom shell 50, and the inside of the bottom shell 50 is installed with drive, drive in Figures 1 to 6 Not shown in the figure, the driver usually includes a motor and a reduction mechanism. The driver is connected with a screw drive assembly. The principle of the screw drive assembly is to use the drive screw 2 to drive the drive nut to move axially, thereby driving the first casing 3 Move relative to the axial direction with the second sleeve 4, and the specific structure is described below.

[0042] The bottom case 50 includes a box body and a box cover. The box cover is fastened to the opening of the box body so that the bottom case 50 has an accommodating space for accommodating the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com