APU system module cooling device and method

A system module and cooling device technology, which is applied in the field of APU system module cooling device, can solve the problems of slow engine heating, high noise, too much engine limitation, etc., and achieve the effect of improving efficiency and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

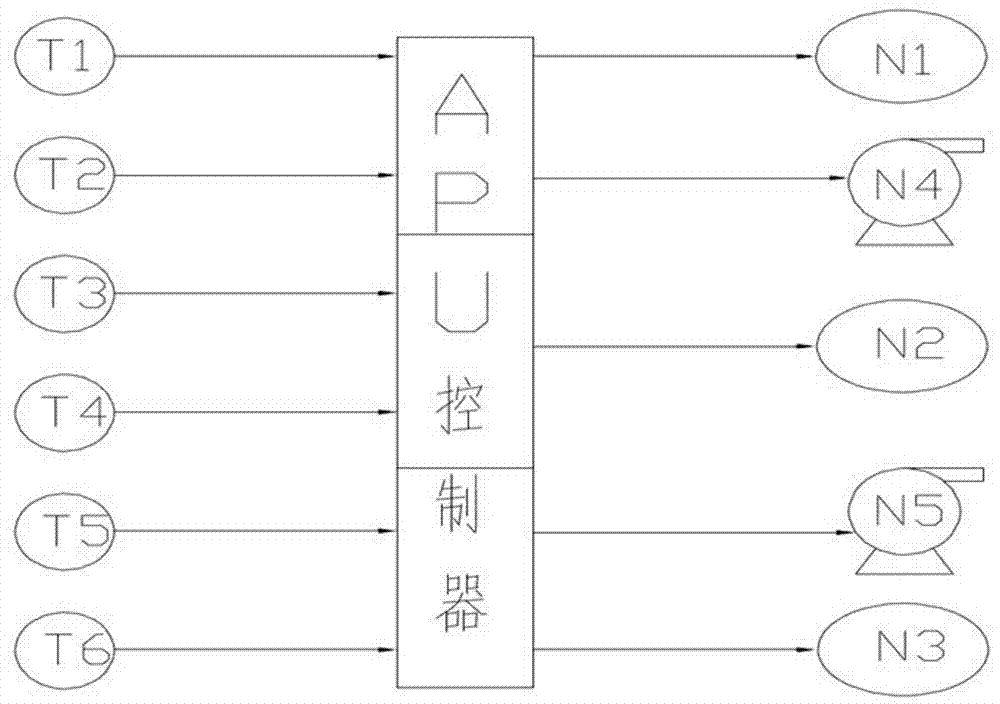

[0018] Such as figure 1 As shown, a cooling device for an APU system module, the APU system includes an engine, a supercharger, a thermostat, a water pump and a generator, and the cooling device includes an engine cooling water circuit, an engine intake cooling air circuit, a generator cooling Waterway and APU controller 5, the engine cooling waterway includes engine radiator and engine cooling electronic fan, the water inlet of the engine radiator is connected with the thermostat, the water outlet of the engine radiator is connected with the water pump, and the engine is connected with the water pump and the thermostat Between, the water inlet and the water outlet of the engine radiator are respectively provided with the engine inlet water temperature sensor 2 and the engine outlet water temperature sensor 1, and the engine cooling electronic fan, the engine inlet water temperature sensor 2 and the engine outlet water temperature sensor 1 are respectively controlled with the A...

Embodiment 2

[0023] This embodiment discloses a cooling method for an APU system module, such as figure 1 Shown is the control principle diagram of this method. The cooling method is based on the cooling device described in Embodiment 1, S01), engine water cooling, the APU controller monitors the engine outlet water temperature through the engine outlet water temperature sensor, and adjusts the engine through hierarchical control. Cool the speed of the electronic fan and water pump so that the engine is in the best working condition; S02), the engine is air-cooled, the APU controller detects the intake air temperature of the intercooler through the intercooler intake temperature sensor, and adjusts the intercooler through hierarchical control The speed of the electronic fan of the generator can reduce the intake temperature of the engine when the engine is working at low speed, and improve the efficiency of the engine; S03), the generator is water-cooled, the APU controller monitors the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com