Movable formwork system and construction method thereof

A mobile formwork and system technology, applied in artificial islands, earthwork drilling, water conservancy projects, etc., can solve problems affecting construction progress, complicated disassembly, labor-intensive, etc., to reduce labor costs, solve the trouble of disassembly and installation, and reduce labor The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

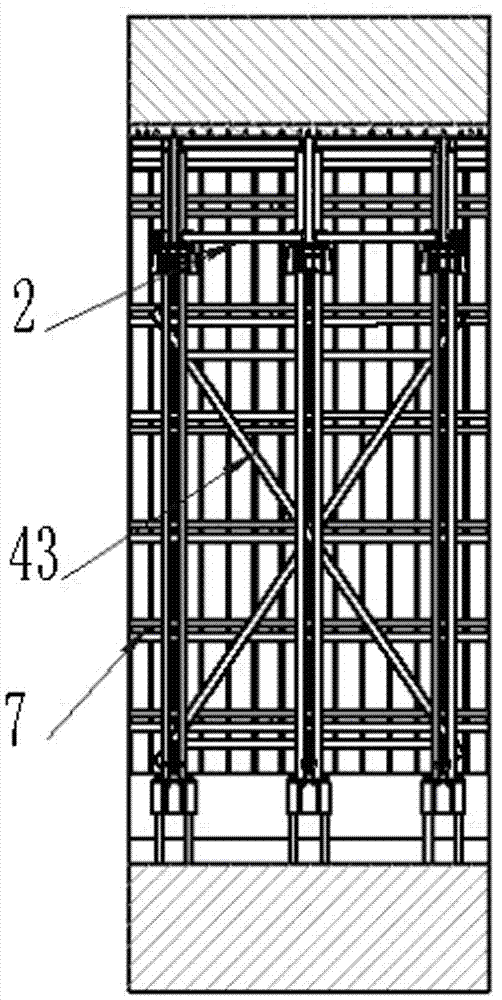

[0039] see Figure 1-5 , a mobile formwork system, including a "Π"-shaped aluminum formwork support plate 1, horizontally arranged transverse truss beams 2, several top support members 3, two vertically arranged vertical truss columns 4, and horizontal support members 5 and a number of vertical supports 6; chamfers are provided at the corners of the aluminum formwork support plate 1; the transverse truss beam 2 abuts against the inner roof of the aluminum formwork support plate 1, and the side walls of the two vertical truss columns 4 respectively abut against On the two inner side walls of the aluminum formwork support plate 1, the upper ends of the two vertical truss columns 4 are respectively fixedly provided with sliding sleeves 41 parallel to the transverse truss beam 2 and having a side surface of "凵" shape, and the lower parts of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com