Stilling basin system

A stilling pool and stilling technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of high building strength requirements, limited energy dissipation efficiency, short service life, etc., and achieve low cost, convenient implementation, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

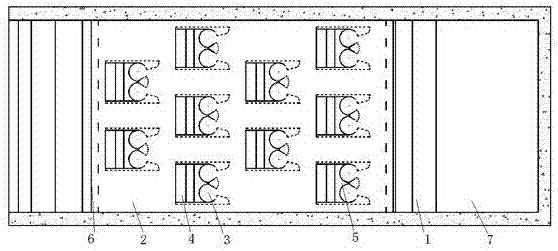

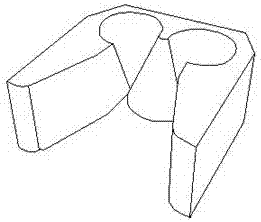

[0033] Specific implementation methods: such as Figure 1-3 As shown, a stilling pool system, including a stilling pool, is characterized in that the water inlet end of the stilling pool is concavely formed with a buffer stilling tank 1, and the height of the bottom surface of the stilling pool in front of the buffer stilling tank 1 is greater than that of the buffer stilling tank. The height of the bottom surface of the force tank, the bottom of the stilling pool in front of the buffer stilling tank 1 is provided with diverter plates 2 at intervals upwards, the rear end of the diverter plate 2 is connected to the front end of the buffer stilling tank, and the diverter plate 2 is in a horizontal state as a whole and is in a horizontal state with the buffer stilling force There is a gap between the bottom surfaces of the stilling pool in front of the groove for the bottom water flow to pass through, and the rear part of the diverter plate 2 is formed with a flow guide structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com