Hard water softening agent and its preparation method and application

A technology of hard water softener and diatomite, which is applied in the direction of complex/solubilizer treatment, etc., can solve the problems of unsafety and high investment cost, and achieve the effect of good physical adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

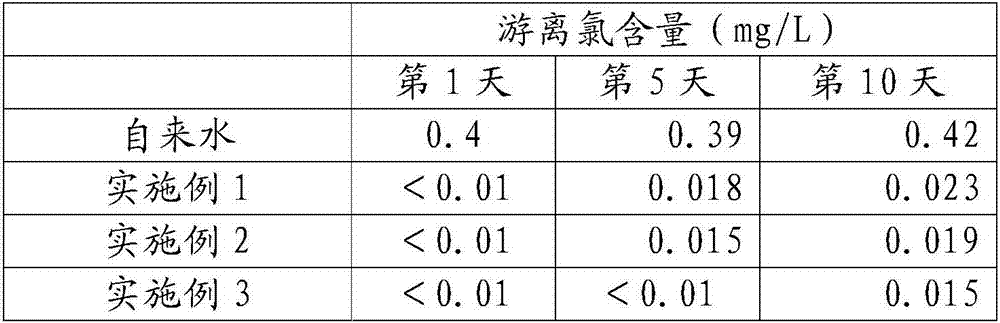

Embodiment 1

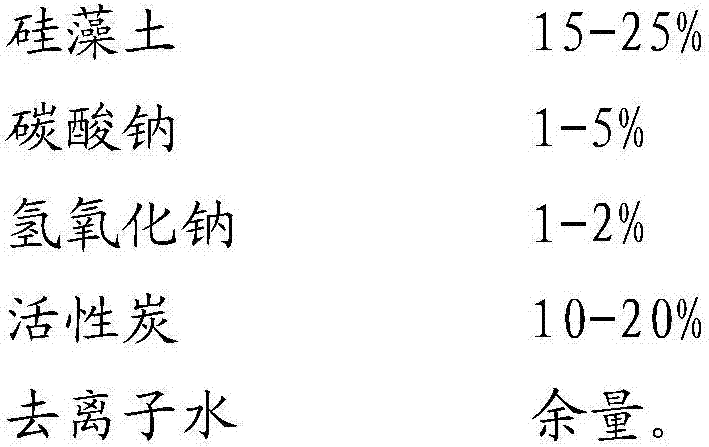

[0013] Preparation of hard water softener: Take 1.5g of diatomite, 0.2g of sodium carbonate, 0.1g of sodium hydroxide, 1g of activated carbon, then add 7.2g of deionized water, mix well, dry and shape, and obtain purification softener 1;

[0014] Preparation of filter column: first put a layer of filter paper in the adsorption column, then add a layer of 5mm filter paper pulp layer, then put 2g of diatomaceous earth, 5g of purification softener 1, and 2g of activated carbon in turn, and then add a layer of 5mm of filter paper pulp, then put a layer of filter paper, and finally drain to obtain the filter column 1.

Embodiment 2

[0016] Preparation of hard water softener: Take 1.5g of diatomaceous earth, 0.5g of sodium carbonate, 0.2g of sodium hydroxide, 2g of activated carbon, then add 5.8g of deionized water, mix well, dry and shape, and obtain purification softener 2;

[0017] Preparation of filter column: first put a layer of filter paper in the adsorption column, then add a layer of 5mm filter paper slurry layer, then put 1g of diatomaceous earth, 8g of purification softener 2, and 1g of activated carbon in turn, and then add a layer of 5mm of filter paper pulp, then put a layer of filter paper, and finally drain to obtain the filter column 2.

Embodiment 3

[0019] Preparation of hard water softener: Take 2.5g of diatomaceous earth, 0.2g of sodium carbonate, 0.1g of sodium hydroxide, 1g of activated carbon, then add 6.2g of deionized water, mix well, dry and shape, and obtain purification softener 3;

[0020] Preparation of filter column: first put a layer of filter paper in the adsorption column, then add a layer of 5mm filter paper pulp layer, then put 4g of diatomaceous earth, 10g of purification softener 3, and 1g of activated carbon in turn, and then add a layer of 5mm of filter paper pulp, then put a layer of filter paper, and finally drain to obtain the filter column 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com