A cable pressing device

A technology of cable pressing and cable board, which is applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as low operating efficiency, cable jumping and tying ropes, and self-dropping of cables, so as to achieve the effect of cable drooping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

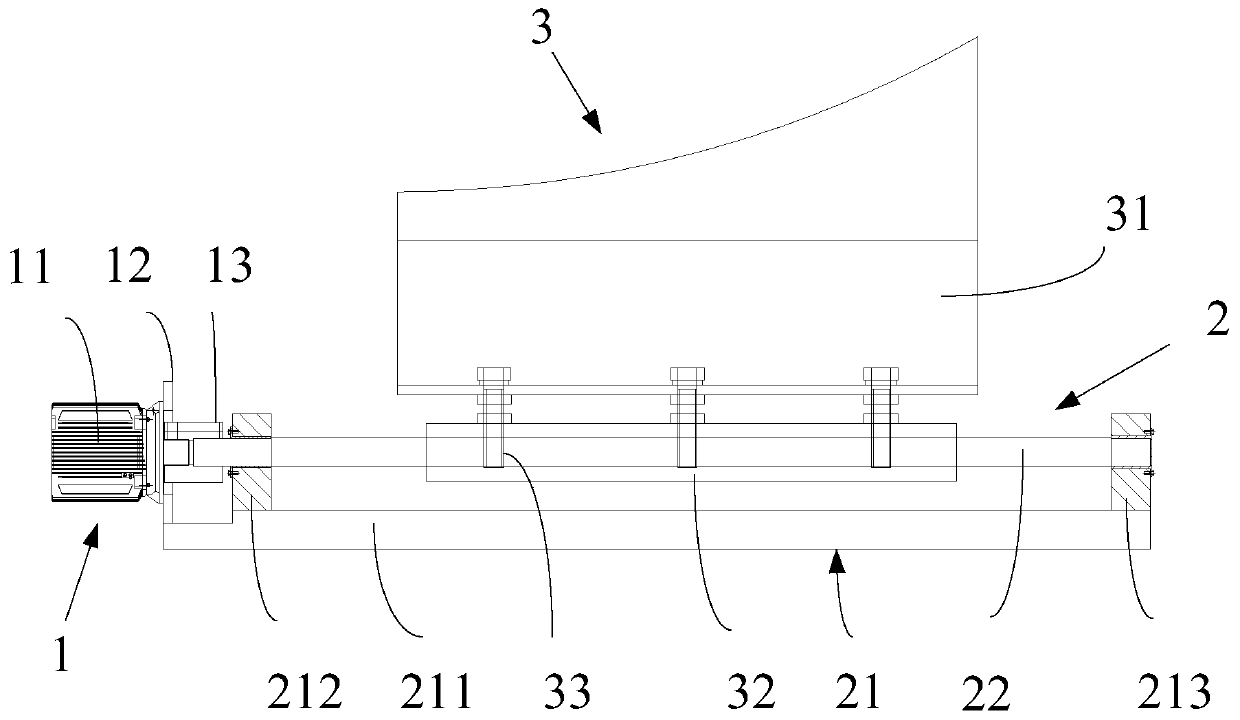

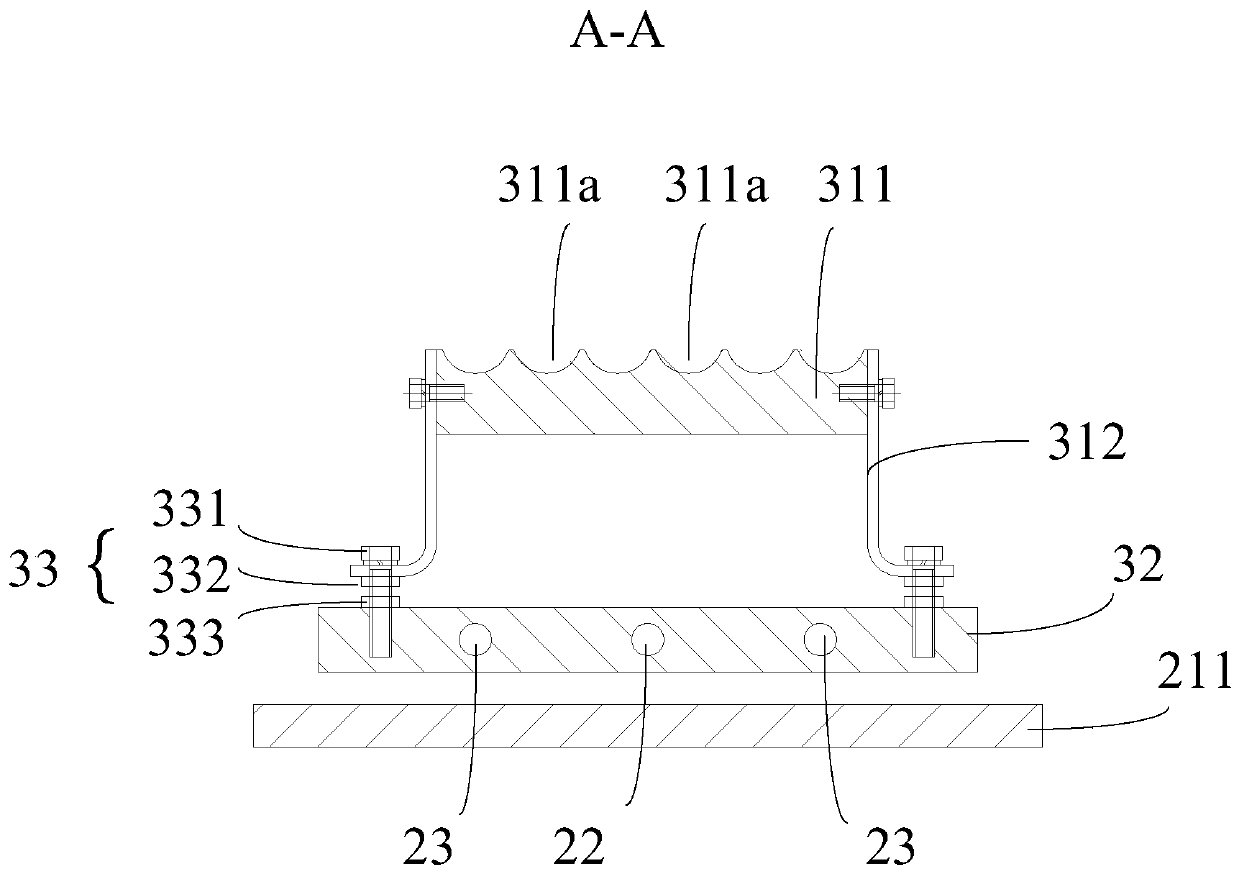

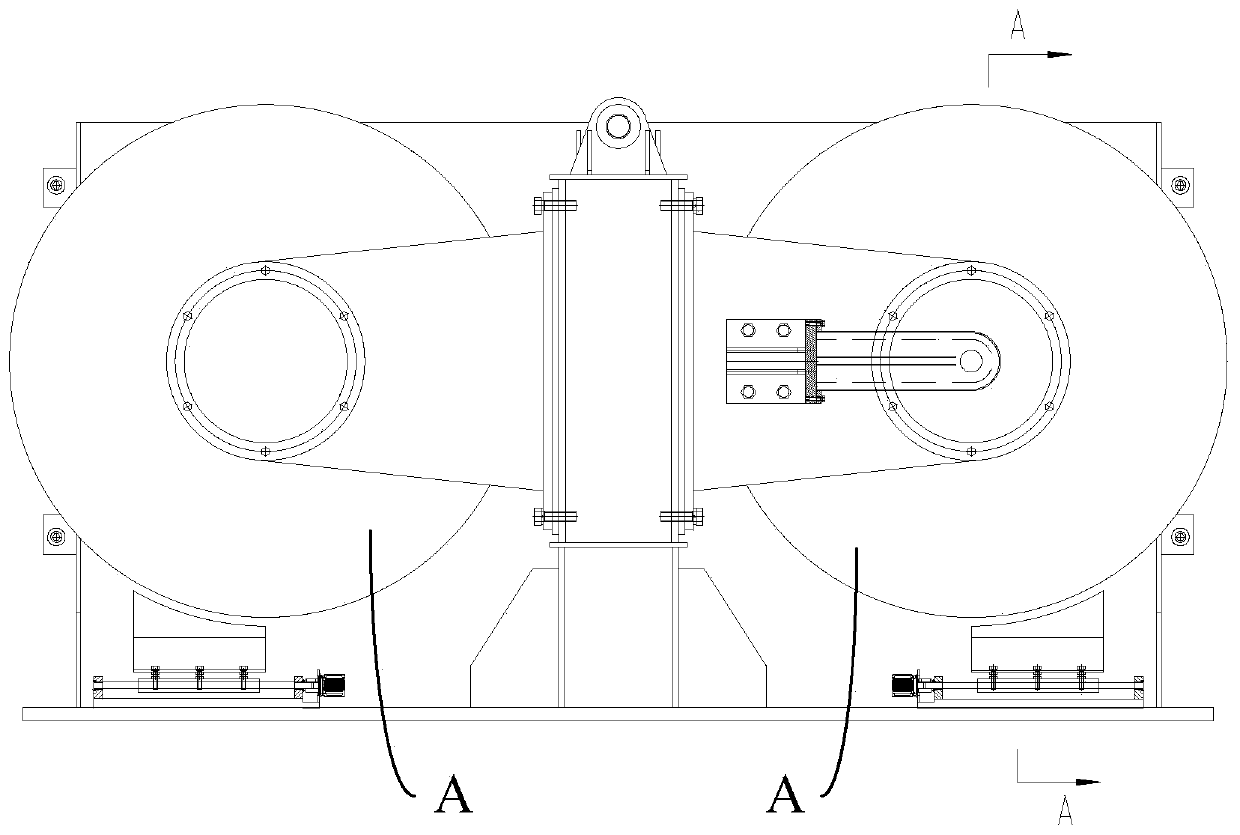

[0029] An embodiment of the present invention provides a cable pressing device, which is suitable for a cable pulling winch. Such as figure 1 As shown, the cable pressing device includes a driving part 1, a supporting part 2 and a cable pressing part 3, and the supporting part 2 includes a support frame 21, a transmission shaft 22 and a guide shaft 23 (see figure 2 ), the two ends of the transmission shaft 22 can be rotatably installed on the support frame 21, the output shaft of the driving part 1 is connected with one end of the transmission shaft 22, the guide shaft 23 and the transmission shaft 22 are arranged parallel to each other, and the two ends of the guide shaft 23 Fixed on the support frame 21, the cable pressing part 3 includes a cable pressing assembly 31 and a sliding part 32, the cable pressing assembly 31 is fixedly installed on the sliding part 32, the sliding part 32 is provided with threaded holes and through holes, and the transmission shaft 22 is inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com