Paper advance mechanism for performance test of stapler or hole puncher and working process of paper advance mechanism

A technology of paper feeding mechanism and punching machine, which is applied in binding and other directions, can solve the problems of repeated operation for a long time, error of test results, and difficult control of spacing, and achieves the effect of saving testing time, saving testing cost, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

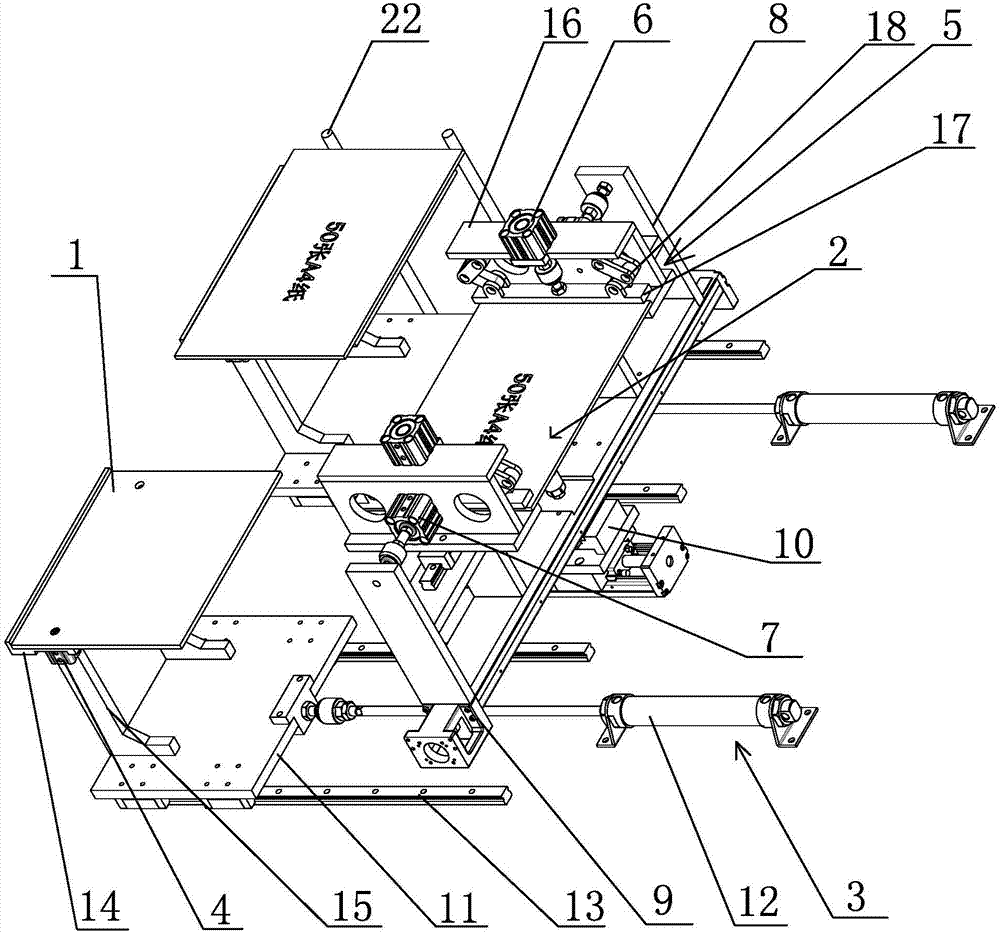

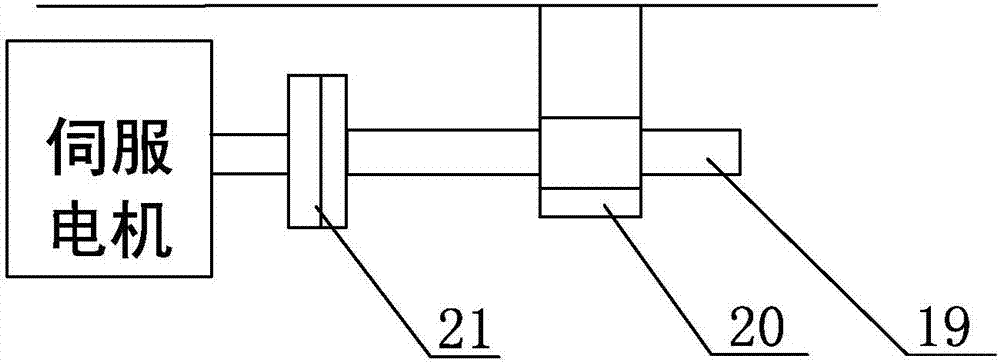

[0031] A paper-feeding mechanism used for book-staple or hole-punching machine performance testing, such as figure 1 As shown, it includes two paper conveying platforms 1 and a paper clamping device 2. The two paper conveying platforms 1 are symmetrically distributed on both sides of the front of the paper clamping device 2. The bottom of the paper conveying platform 1 is set to drive the paper conveying platform 1 along the Y The Y-axis cylinder drive mechanism 3 moving in the axial direction and the Z-axis cylinder drive mechanism 4 that drives the paper transport platform 1 to move in the Z-axis direction. The paper clamping device 2 includes two paper clamps for clamping the sides of the paper. Part 5, the area of the paper release area formed between the two paper clamping parts 5 is larger than the area of the paper transport platform 1 and smaller than the entire area of the paper to be stapled or punched, and the top of the paper clamping part 5 is provided with a...

specific Embodiment 2

[0035] The above-mentioned working process of the paper-feeding mechanism used for the performance test of the stapler or punching machine includes the following steps:

[0036] (1) Feed the paper into the paper clamping device 2, and further feed one side of the paper into the paper storage area of the stapler or puncher, as follows:

[0037] A. Turn on the first servo motor 9, drive the U-shaped receiving frame 8 to move along the X-axis direction through the first screw transmission mechanism, thereby driving the paper clamping device 2 fixedly connected with the U-shaped receiving frame 8 to move along the X-axis direction until the paper clamping device 2 Move to the position corresponding to the paper transport platform 1 loaded with paper;

[0038] B. Turn on the Z-axis cylinder drive mechanism 4, and control the Z-axis cylinder drive mechanism 4 to move upwards, thereby driving the paper conveying platform 1 loaded with paper to move upwards along the Z-axis until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com