Position welding device for fuel oil radiator installation seat

A technology of positioning welding and mounting seat, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of poor consistency, large welding deformation, easy to break, etc., to reduce the dependence on experience, simple shape of tooling, and ensure appearance quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] 1. According to the process requirements, prepare a total of 1 cylinder body 1 and a total of 4 mounting seats 2.

[0045] 2. Assembly and positioning:

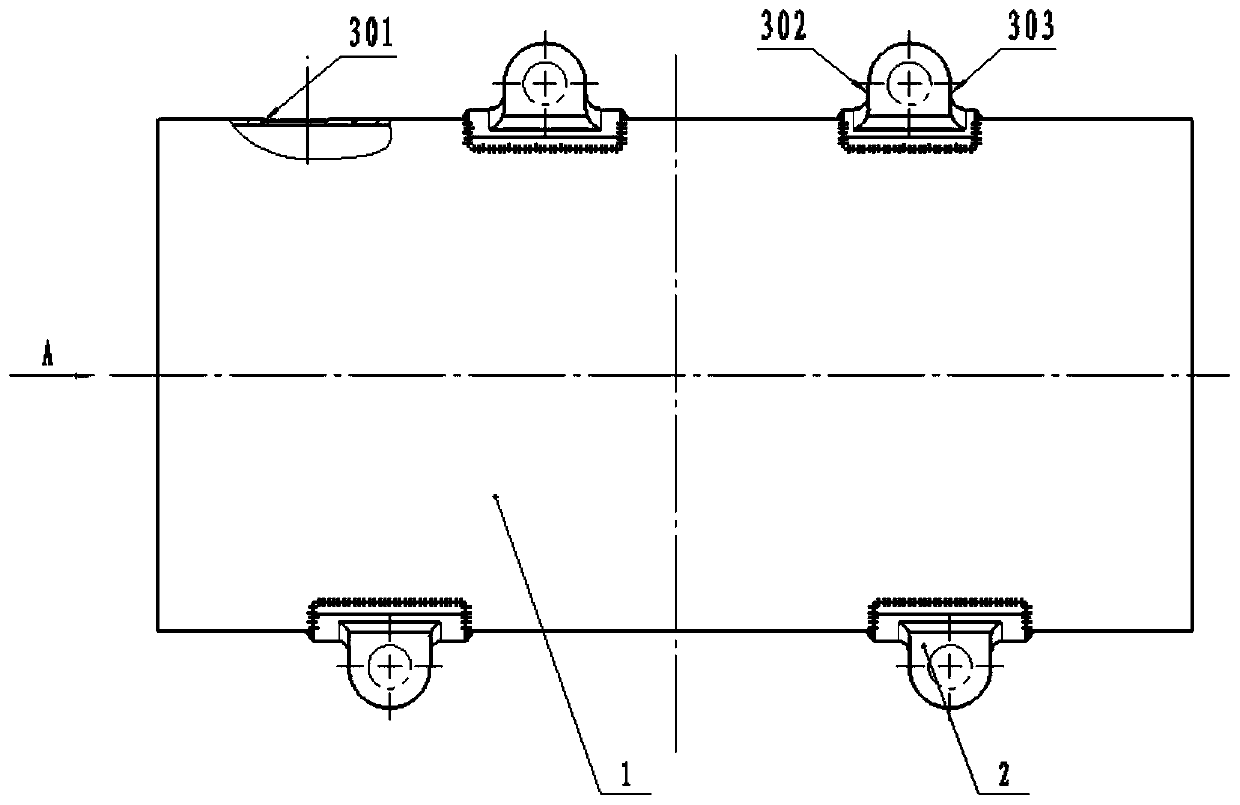

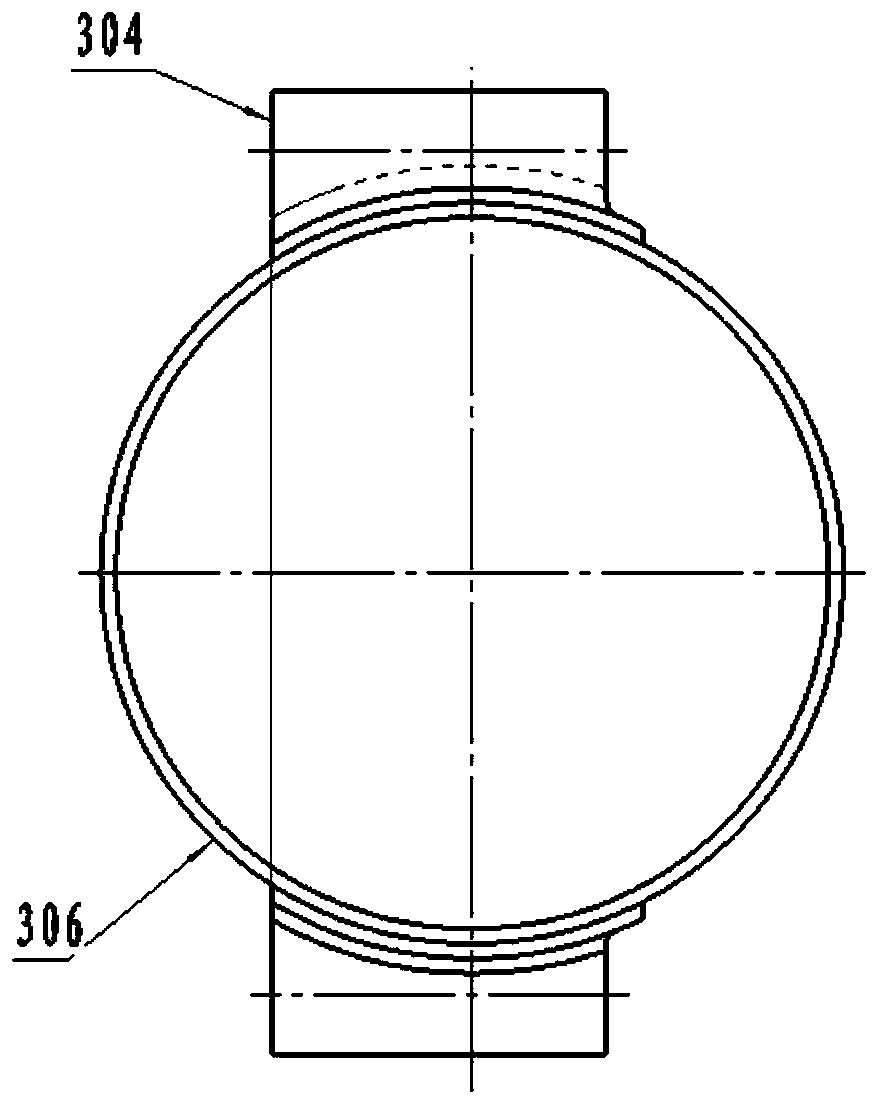

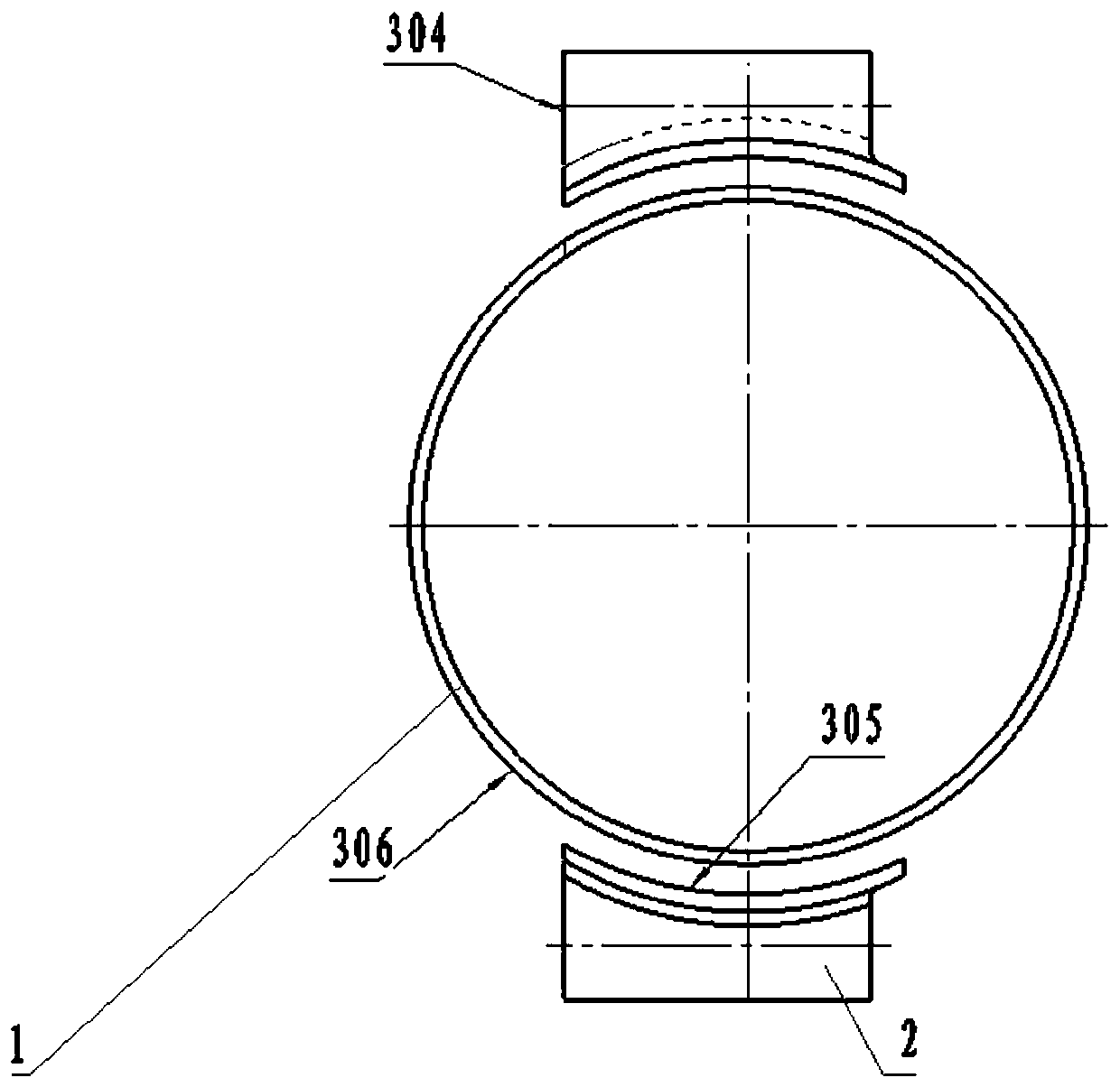

[0046] a) according to Figure 4 , Figure 5 The cylinder is installed on the positioning block 6, so that the outer circular surface of the cylinder 306 ( image 3 ) and the arc surface 503 of the positioning block 6 ( Figure 7 ) coincide, adjust the position of the cylinder, insert the positioning mandrel 3 into the cylinder hole 301 ( figure 1 ) to fix the cylinder. Then rotate the first compression screw 9, push the briquetting block 8, and press the cylinder tightly between the briquetting block and the positioning block.

[0047] 2) According to Figure 4 , Figure 5 The mounting seat is assembled in the mounting seat positioning groove of the positioning block 6, so that the first positioning surface 302 and the second positioning surface 303 ( figure 1 ) and the 502, 501 faces of the positioning block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com