Welding seam tracking control device and method based on cross laser device

A tracking control and laser technology, applied in manufacturing tools, welding equipment, welding accessories, etc., can solve problems such as low detection accuracy, starting point positioning of fillet welds, and random errors in dynamic detection of welds, to increase the amount of detection information, The effect of increasing the degree of freedom of rotation and preventing molten iron from splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. The examples are implemented on the premise of the technical solutions of the present invention, and detailed implementation methods and specific operation processes are given, but the scope of protection of the claims of the application is not limited to the following examples.

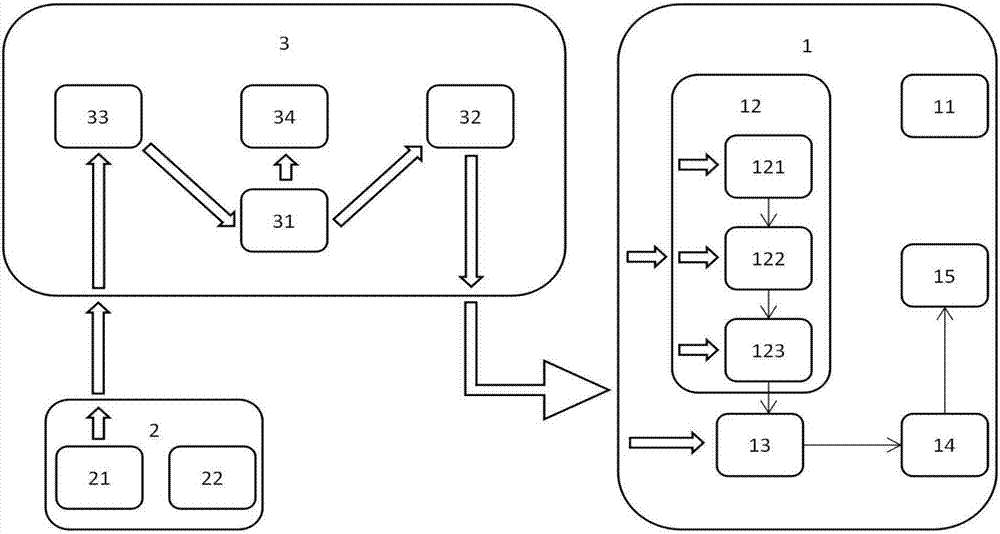

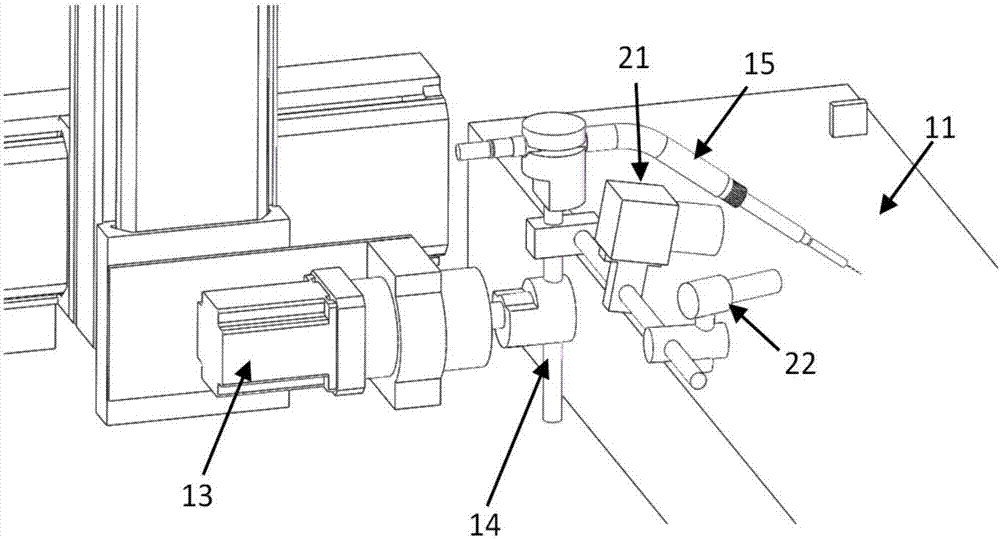

[0029] The present invention provides a welding seam tracking control device based on a cross-type laser (referred to as a control device or device, see Figure 1-3 ) includes a four-degree-of-freedom robot 1, a visual sensor 2 and an integrated control cabinet 3;

[0030] The four-degree-of-freedom robot 1 includes a working platform 11, a mobile module 12, a Y-axis stepper motor 13, a bracket 14, and a welding torch 15; the mobile module 12 is three ball screw-type straight lines driven by an AC servo motor The mobile module includes an X-axis direction mobile module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com