Sludge shredding device

A chopping device and sludge technology, which is applied in the field of mechanical devices, can solve the problem that large sludge cannot be completely dried and dehydrated, and achieve the effects of uniform sludge cutting, stable movement, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

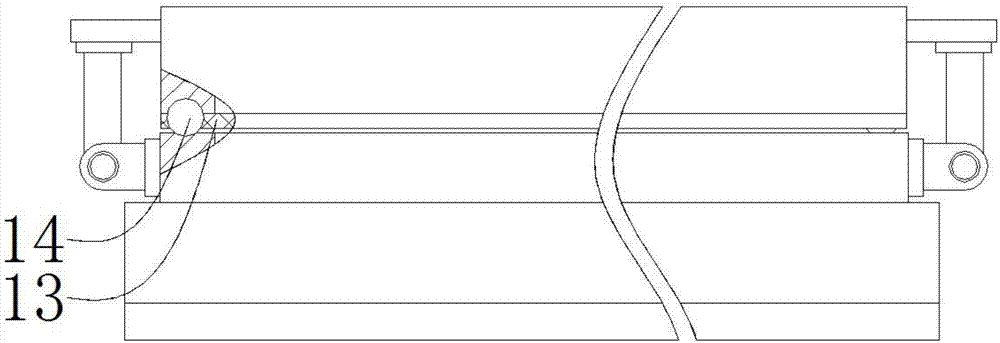

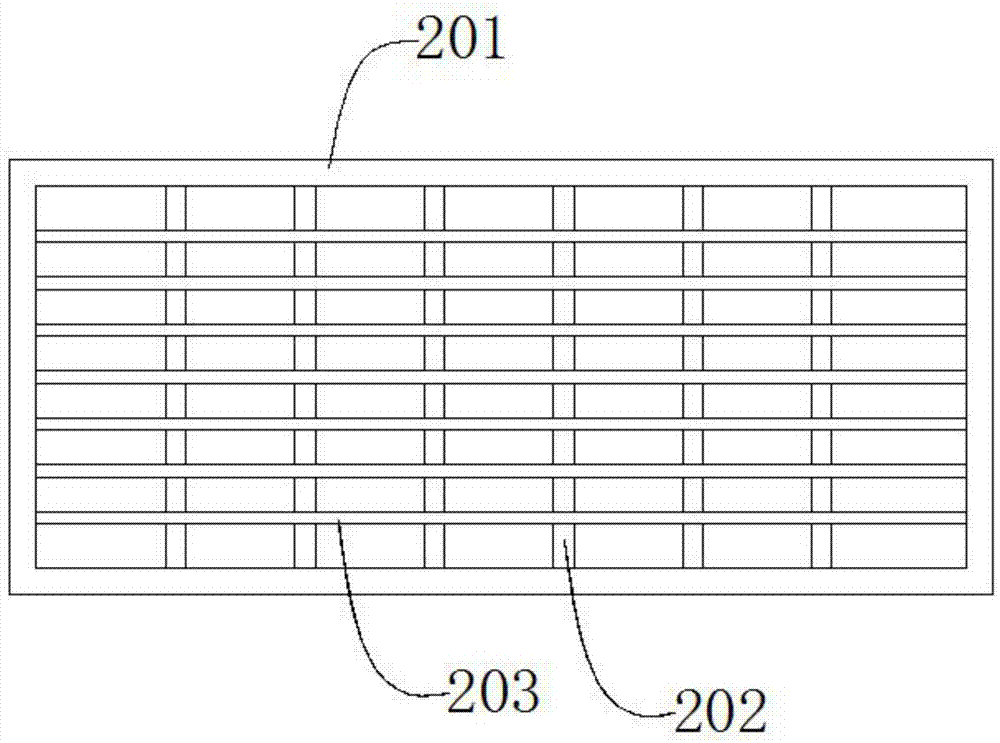

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a sludge shredding device includes a support plate 1, a lower grid 2, a guide rod 3, an upper grid 4, a bracket 5, a power mechanism 6, a rotating shaft 7, a cam 8, a slide plate 9, and a guide wheel 10 , connecting plate 11, reset mechanism 12, limit plate 13, steel ball 14, described lower grid 2 is located at the upper end of support plate 1, described lower grid 2 is connected with support plate 1 threadedly, described lower grid A guide rod 3 is provided on both sides of the grid 2, and the guide rod 3 is threadedly connected with the lower grid 2, and the upper grid 4 is located at the upper end of the lower grid 2 and runs through the guide rod 3. The grille 4 is connected to the guide rod 3 with gaps, the bracket 5 is located at the upper end of the support plate 1, the bracket 5 is screwed to the support plate 1, the power mechanism 6 is located on the right side of the bracket 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com