Panel resetting structure of self-wringing mop

A technology of reset structure and panel, applied in the direction of floor cleaning, carpet cleaning, cleaning equipment, etc., can solve the problems of lack of buffer, loose panel and mop seat, fast reset speed of wipes, etc., to improve the sense of control, improve stability and The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

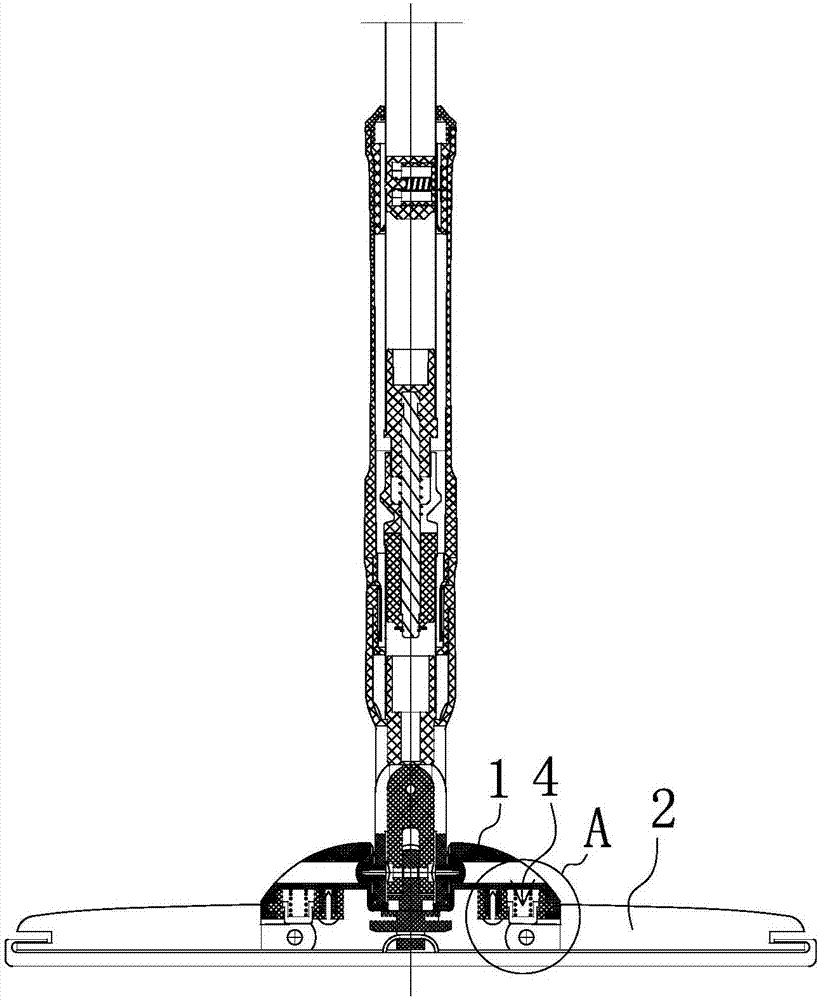

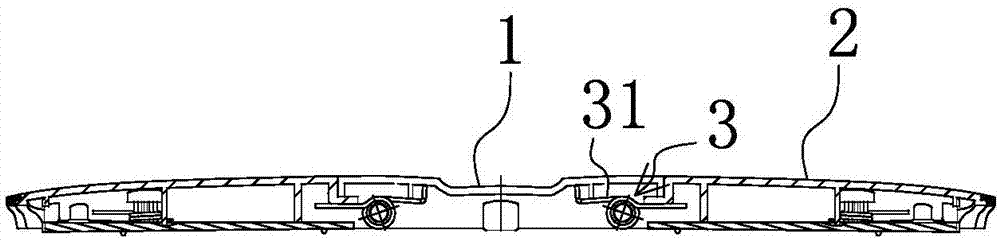

[0041] Such as Figure 1-3 As shown, the panel reset structure of the self-wringing mop includes a mop seat 1 and a panel 2 that is rotatably connected to the mop seat 1, and a panel rotation elastic mechanism 3 is provided between the mop seat 1 and the panel 2, and the mop seat 1 and the panel 2 is also provided with a panel rotation speed change mechanism, preferably, the panel rotation elastic mechanism 3 here is a torsion spring assembly 31 arranged between the mop seat 1 and the panel 2, under the action of the torsion spring assembly 31, it can make The panel 2 is reset, and the main function of the panel rotation speed change mechanism here is to provide damping to the reset force of the torsion spring assembly 31, thus slowing down the speed of panel reset.

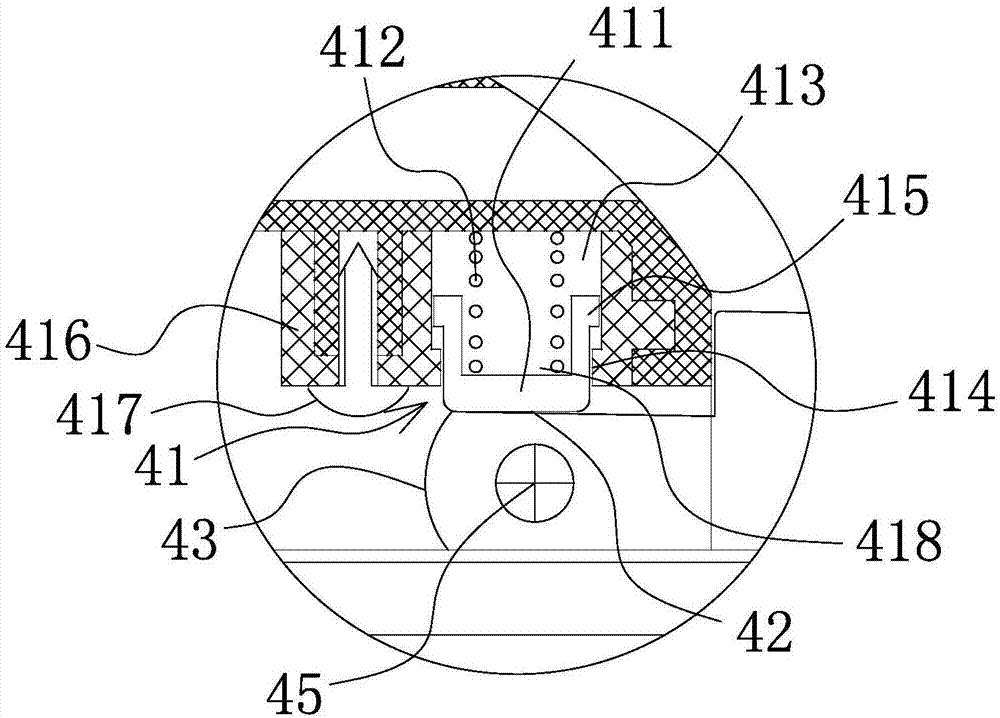

[0042] Specifically, the panel rotation speed change mechanism here includes a damping structure 4 arranged between the mop base 1 and the panel 2 , for example, the damping structure 4 here is an elastic damping...

Embodiment 2

[0049] Such as Figure 8-10 As shown, the structure, principle and implementation steps of this embodiment are similar to those of Embodiment 1, the difference is that the second pressing surface 43 here is an inclined plane, when the second pressing surface 43 here is an inclined plane, along with When the panel 2 swings back from the inside to the outside, the pressing area 44 will gradually change from the outside of the hinge point 45 between the panel 2 and the mop seat 1 to the inside of the hinge point 45 between the panel 2 and the mop seat 1. The difference is that , when the pressing area 44 is located outside the hinge point 45 of the panel 2 and the mop seat 1, the elastic pressing member 41 plays a role of damping the swing reset of the panel 2, realizing the effect of reducing the swing speed of the panel 2, when the second When the pressing surface 43 is in close contact with the first pressing surface 42, it has the function of a brake, which can make the panel...

Embodiment 3

[0051] Such as Figure 11-13 As shown, the structure, principle and implementation steps of this embodiment are similar to the first embodiment, the difference is that the damping structure 4 here is also an elastic damping structure, but different from the first and second embodiments, the damping structure 4 here It includes an elastic sheet 46 arranged on the mop seat 1 and a blocking surface 47 arranged on the panel 2. The outer end of the elastic sheet 46 is arranged obliquely downward, and the elastic sheet 46 described in the process of unfolding the panel 2 The outer end can abut against the blocking surface 47 , preferably, the blocking surface 47 here is an inner wall of a slot 48 provided on the panel 2 . That is to say, when the panel 2 is reset under the action of the torsion spring assembly 31, when the panel 2 is reset to a certain angle, the end of the elastic sheet 46 is inserted into the slot 48 and the end is in contact with the inner wall of the slot 48 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com