Caramel condensed milk

A technology for condensed milk and caramel, applied in dairy products, applications, milk preparations, etc., can solve the problems of unstable crystallization process, shortened product shelf life, difficult to control reaction, etc., and achieves good market prospects, easy implementation, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

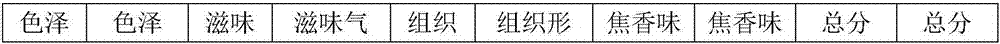

Image

Examples

Embodiment 1

[0029] A caramelized condensed milk prepared as follows:

[0030] (1) Boiling of syrup liquid

[0031] Add 180kg of white granulated sugar to the sugar melting tank, heat to 190°C, add 100kg of water and cool down to 85°C, keep warm for 30min, and obtain a syrup liquid with a solid content of 70%;

[0032] (2) Ingredients

[0033] Add 700kg of water to No. 1 batching tank, heat to 60°C, add 255kg of white sugar, then heat to 98°C, keep warm for 10min, and obtain ingredient I;

[0034] Add 800kg of water, 280kg of whole milk powder, 25kg of anhydrous butter, 5kg of mono- and diglyceride fatty acid esters and 260kg of syrup liquid into the No. 2 batching tank, and then stir within 20 minutes (speed 75 rpm, the same below) Heating to 60°C while heating to obtain ingredient II;

[0035] (3) Sterilization

[0036] Pump the ingredient II into the tubular sterilizer, treat it at 91°C for 30 seconds, then use circulating water to quickly cool it down to 65°C, and put it into the s...

Embodiment 2

[0043] A caramelized condensed milk prepared as follows:

[0044] (1) Boiling of syrup liquid

[0045] Add 180kg of white granulated sugar to the sugar melting tank, heat to 170°C, add 100kg of water and cool down to 75°C, keep warm for 25min, and obtain a syrup with a solid content of 67%;

[0046] (2) Ingredients

[0047] Add 680kg of water to the No. 1 batching tank, heat to 50°C, add 235kg of white sugar, then heat to 90°C, keep it warm for 9 minutes to obtain ingredient I;

[0048] Add 750kg of water, 260kg of whole milk powder, 20kg of anhydrous butter, 5kg of mono- and diglyceride fatty acid esters and 250kg of syrup liquid into the No. 2 batching tank, and then heat to 50°C while stirring within 20 minutes to obtain ingredient II;

[0049] (3) Sterilization

[0050] Pump the ingredient II into the tubular sterilizer, treat it at 91°C for 30 seconds, then use circulating water to quickly cool it down to 60°C, and put it into the storage tank for use;

[0051] (4) va...

Embodiment 3

[0057] A caramelized condensed milk prepared as follows:

[0058] (1) Boiling of syrup liquid

[0059]Add 180kg of white granulated sugar to the sugar melting tank, heat to 180°C, add 100kg of water and cool down to 80°C, keep warm for 20min, and obtain a syrup liquid with a solid content of 68%;

[0060] (2) Ingredients

[0061] Add 720kg of water to No. 1 batching tank, heat to 55°C, add 275kg of white sugar, then heat to 95°C, keep it warm for 8 minutes to obtain ingredient I;

[0062] Add 850kg of water, 300kg of whole milk powder, 30kg of anhydrous butter, 5kg of mono- and diglyceride fatty acid esters and 270kg of syrup liquid into the No. 2 batching tank, and then heat to 55°C while stirring within 20 minutes to obtain ingredient II;

[0063] (3) Sterilization

[0064] Pump the ingredient II into the tubular sterilizer, treat it at 91°C for 30 seconds, then use circulating water to quickly cool it down to 62°C, and put it into the storage tank for use;

[0065] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com