One-drag-one type laminaria japonica harvesting device

A technology of harvesting device and kelp, which is applied to harvesters, tow/push equipment, transportation and packaging, etc., can solve the problems of time-consuming and labor-intensive, low harvesting efficiency, difficult transportation, etc., and achieves improved harvesting efficiency, simple structure, and convenient disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

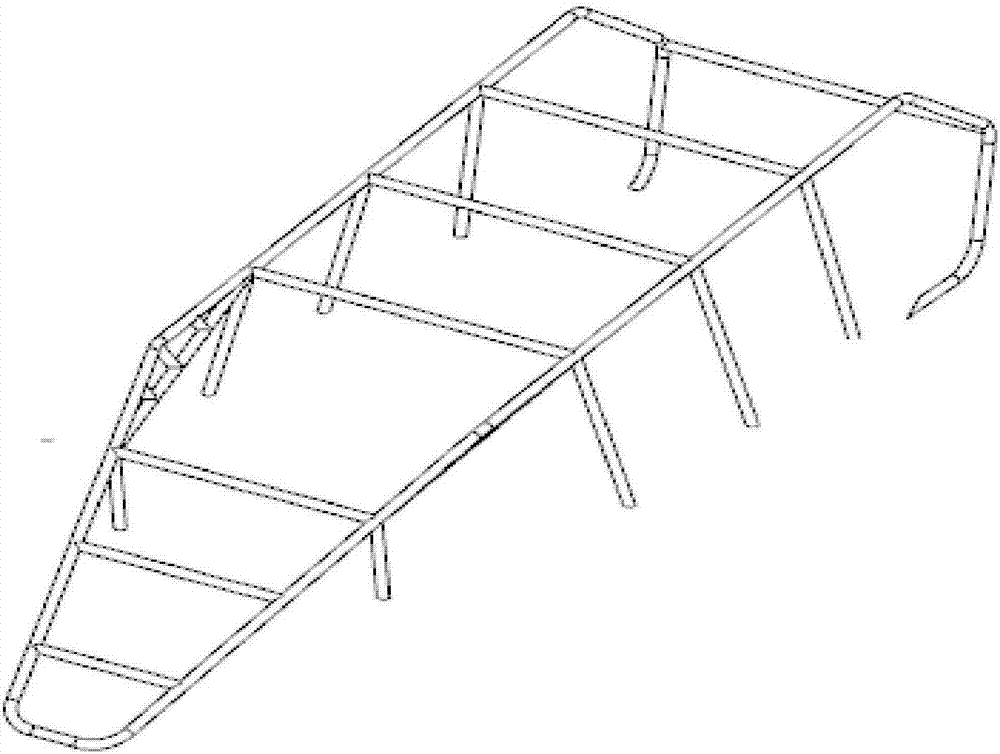

[0010] A "one-to-one" type kelp harvesting device adopts an ordinary ship as the hull (1) of the kelp harvesting device, supported by a detachable kelp harvesting frame (2), and the hull (1) of the kelp harvesting device and the transport ship (5) are connected by cables , and the stern is facing the stern, and the rubber wheel (7) in the middle plays a role in buffering and alleviating collisions, and wherein the transport ship (5) serves as the use of the kelp harvesting cabin. The detachable kelp harvesting frame (2) stretches into below the sea surface, and the engine (4) provided by the kelp harvesting device hull (1) itself provides power to advance the kelp seedling rope together with the kelp, and along with the kelp harvesting device hull (1 ) and the transport ship (5) move forward together, and the kelp seedling rope and the kelp are transmitted to the transport ship (5) after crossing the cockpit (3) backward together, and at this moment, the unbuckled workers (6) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com