Door stop structure

A door suction and slideway technology, applied in door/window fittings, building structures, buildings, etc., can solve the problems of no buffer structure, device damage, loud noise, etc., and achieve the effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

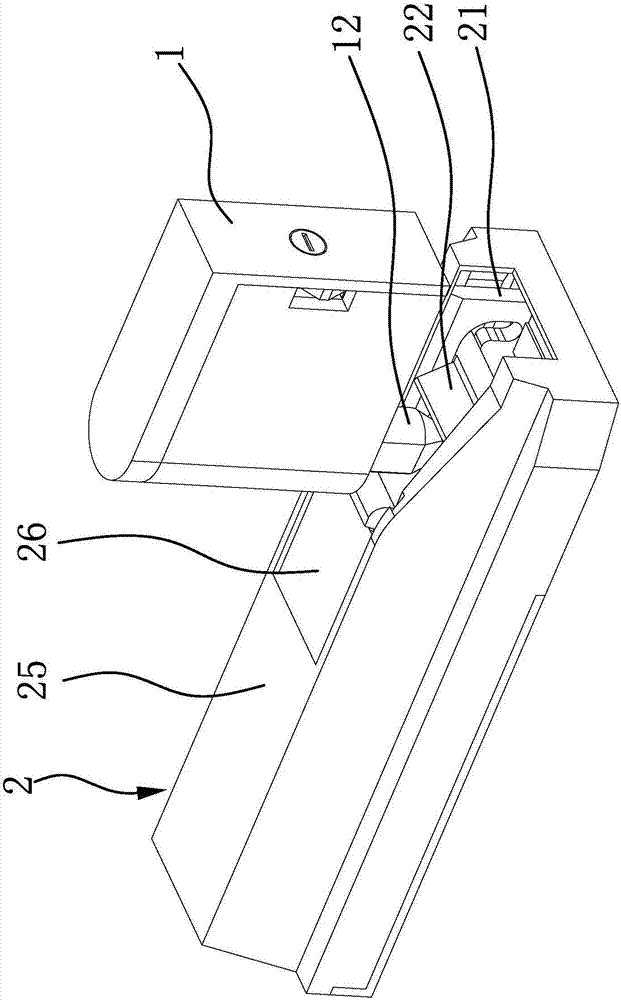

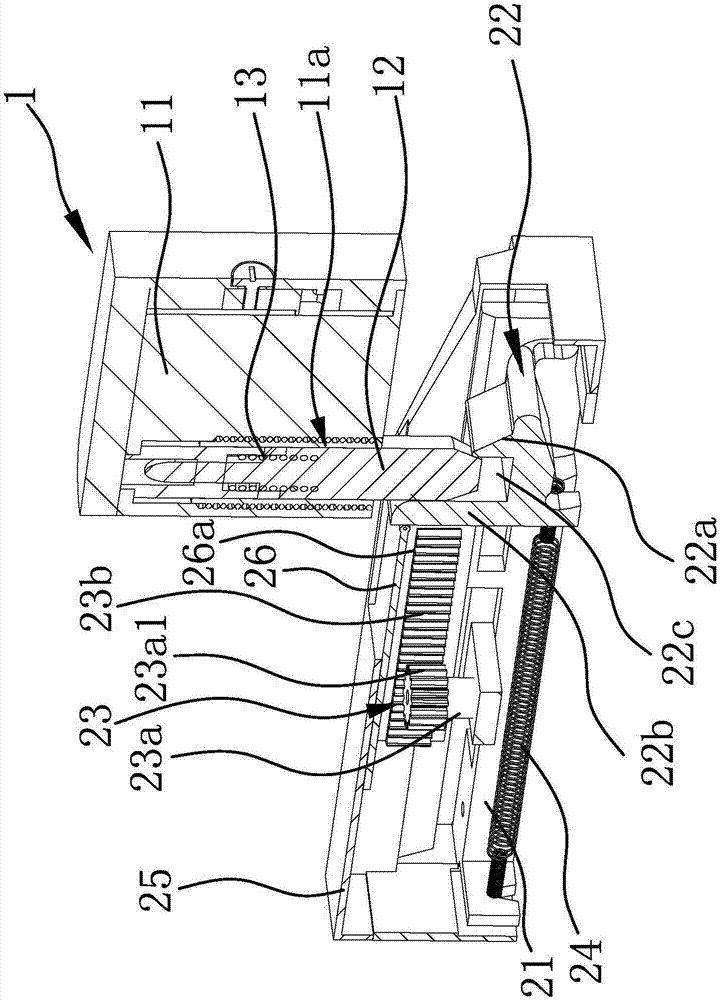

[0042] Such as figure 1 , figure 2 and image 3 As shown, the door suction structure includes a positioning piece 1 and a buffer assembly 2 arranged oppositely. The positioning piece 1 has a snap joint 12; the buffer assembly 2 includes a mounting seat 21 and a return elastic member 24, and the mounting seat 21 is provided with a slideway 21a. , the slideway 21a is provided with a trigger slider 22 capable of reciprocating movement, the trigger slider 22 has a clamping part 22a connected with the clamp joint 12; It is the suction end 21a2, and the clamping joint 12 can engage or disengage between the clamping end 21a1 of the slideway 21a and the clamping part 22a of the trigger slider 22; The sliding block 22 is a rotation damping structure 23 that generates resistance when it moves from the locking end 21a1 of the slideway 21a to the suction end 21a2; The elastic restoring force of the joint end 21a2. Specifically, the mounting base 21 is provided with a housing 25, the ...

Embodiment 2

[0046] Such as Figure 4 and Figure 5 As shown, this embodiment is substantially the same as Embodiment 1, the difference is that the rotation damping structure 23 in this embodiment includes a rack 23b fixed on the mounting base 21 and a rotating body 23a connected to the trigger slider 22 The rotating body 23a has buffer damping and is hinged with the trigger slider 22 through the connecting plate; the rotating body 23a has a gear 23a1; the rack 23b is arranged along the length direction of the slideway 21a, and the gear 23a1 is meshed with the rack 23b; 23a is connected to the trigger slider 22 and can move accordingly, the rack 23b is fixed on the mounting seat 21, and the snap joint 12 on the positioning part 1 pushes the trigger slider 22 from the locking end 21a1 of the slideway 21a to the suction end 21a2 When moving, the rotating body 23a and the gear 23a1 on the rotating body 23a are driven to move, the rack 23b meshes with the gear 23a1 on the rotating body 23a, a...

Embodiment 3

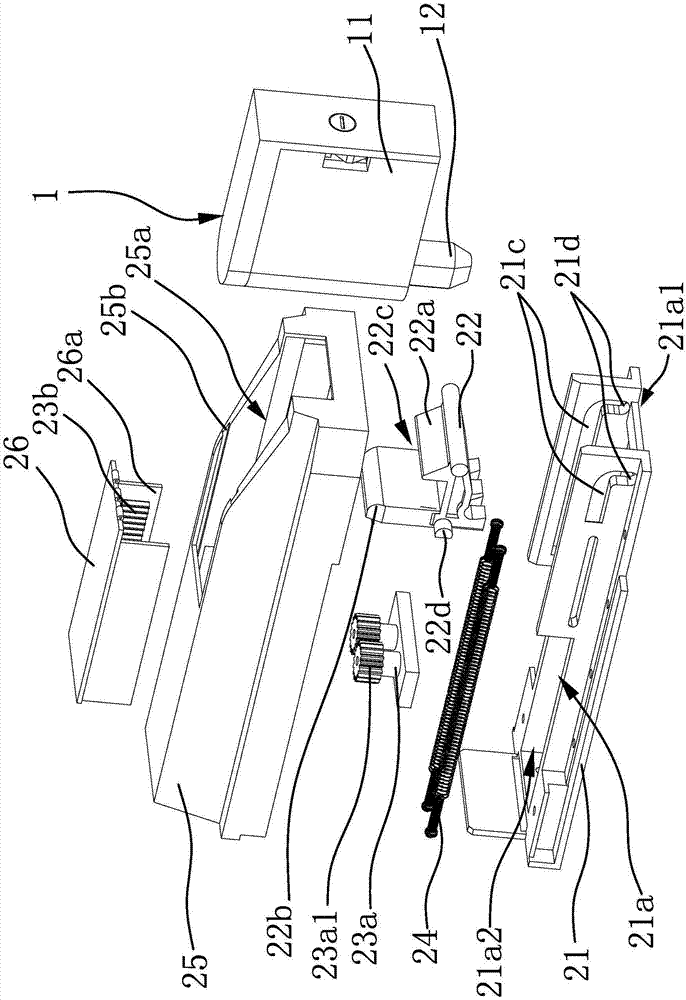

[0048] Such as Figure 6 and Figure 7 As shown, this embodiment is substantially the same as Embodiment 2, the difference is that the specific installation position of the rack 23b in the rotation damping structure 23 and the specific structure of the rotating body 23a are different; the number of racks 23b in this embodiment is two and are respectively located on both sides of the slideway 21a. The rack 23b is arranged along the length direction of the slideway 21a. The rotating body 23a is hinged with the trigger slider 22. The rotating body 23a has a horizontal setting and both ends pass through the rotating body 23a. The external rotating shaft 23a2; the two ends of the rotating shaft 23a2 have a gear 23a1 which is in transmission connection with the rack 23b. When the snap joint 12 on the positioning member 1 pushes the trigger slider 22 to move from the locking end 21a1 of the slideway 21a to the suction end 21a2, it drives a rotating body 23a to move, and both ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com