A kind of antibacterial silver-plated fiber core-spun yarn, antibacterial fabric and antibacterial socks

A silver-plated fiber and core-spun yarn technology, which is applied in fiber treatment, fiber type, biochemical fiber treatment, etc., can solve problems such as unwinding failure, difficult transmission of unwinding mechanism, and influence on the application of silver-plated fiber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

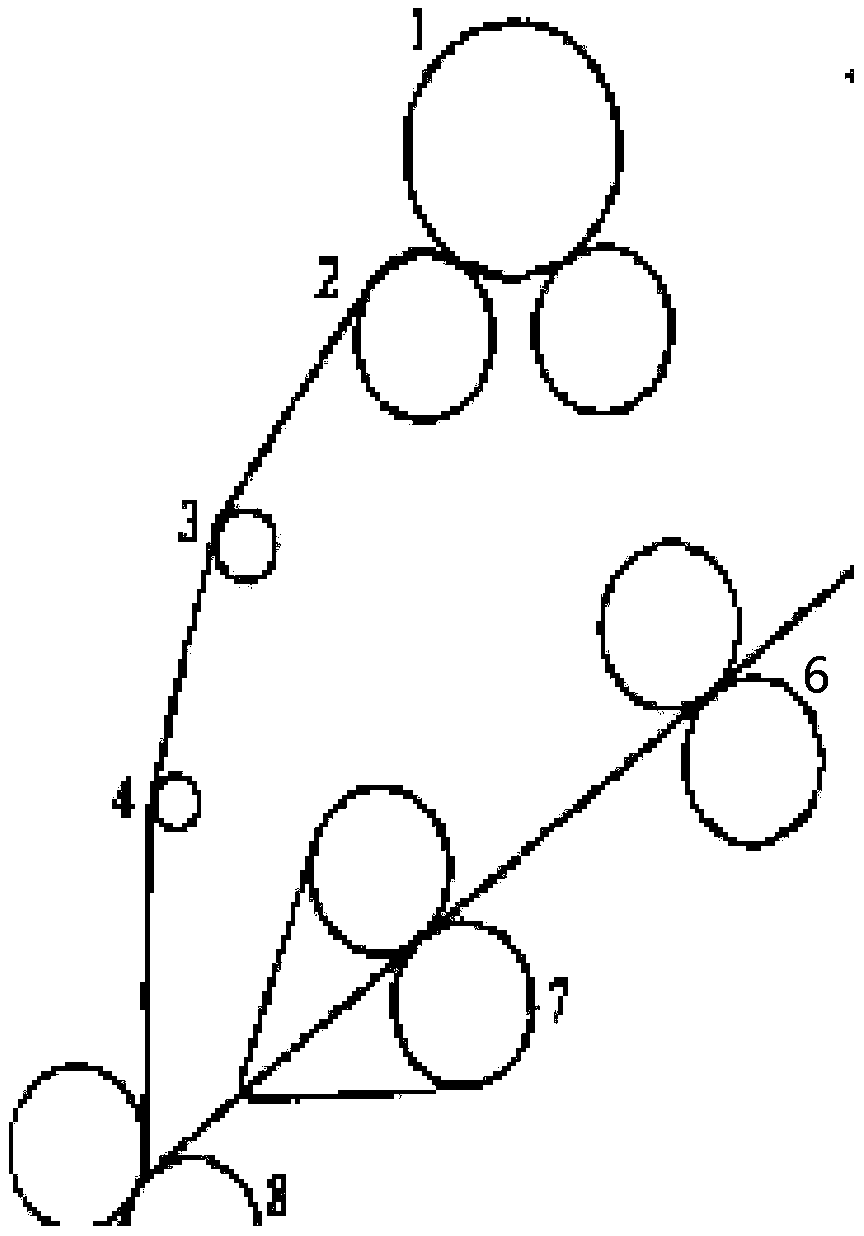

Image

Examples

preparation example Construction

[0044] The preparation method of silver salt solution:

[0045] (1) 1g AgNO 3 First dissolve in 60 mL of water, and add 30 wt% ammonia water dropwise with constant stirring until the precipitated Ag2 The O precipitate was completely dissolved, and 0.1 mol / L NaOH was added to make the solution black again; continue to add ammonia water dropwise until it was completely clear to obtain A solution;

[0046] (2) dissolve 40g glucose and 20g tartaric acid in 500mL water, boil for 10min, add 100mL ethanol and 400mL water after cooling to obtain B solution;

[0047] (3) Mix the two solutions of A and B in a volume ratio of 1:2 to obtain a silver salt solution.

Embodiment 1

[0049] Preparation method of silver-plated fiber:

[0050] S1 surface roughening treatment: add cotton fiber 6 fiber to 100g / L sodium hydroxide solution, soak it for 60min at 60 ℃, to obtain cotton fiber 6 fiber after surface roughening treatment; the cotton fiber 6 fiber is combined with The bath ratio of sodium hydroxide solution is 1Kg: 20L;

[0051] S2 surface sulfhydrylation treatment: add 30 parts by weight of roughened cotton fiber 6 fibers and 3 parts by weight of mercapto compound into 80 parts by weight of water, adjust the pH to 4 with 0.1 mol / L hydrochloric acid, add 2 parts by weight of 1- (3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 2 parts by weight of N-hydroxysuccinimide were stirred at L sodium hydroxide was adjusted to pH 7, 0.3 parts by weight of tris(2-carboxyethyl) phosphine hydrochloride was added, and stirred at 30°C and 1000 rpm for 20 hours to obtain cotton fiber 6 after surface thiolation treatment. fiber;

[0052] S3 Electroless ...

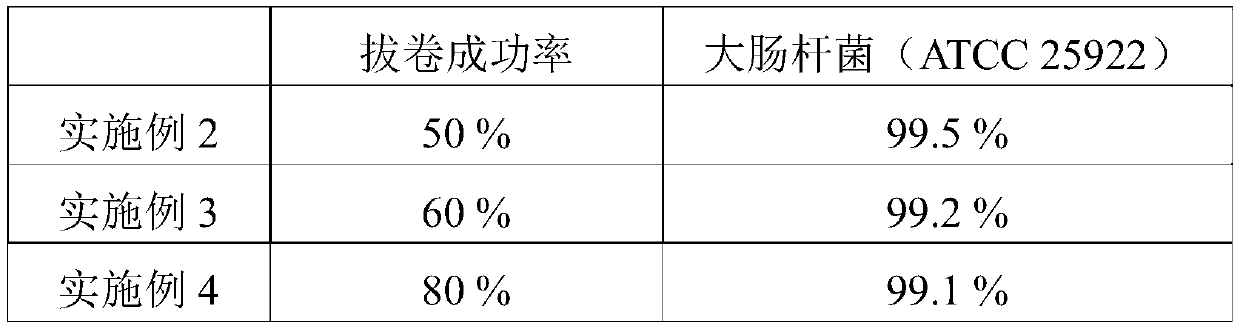

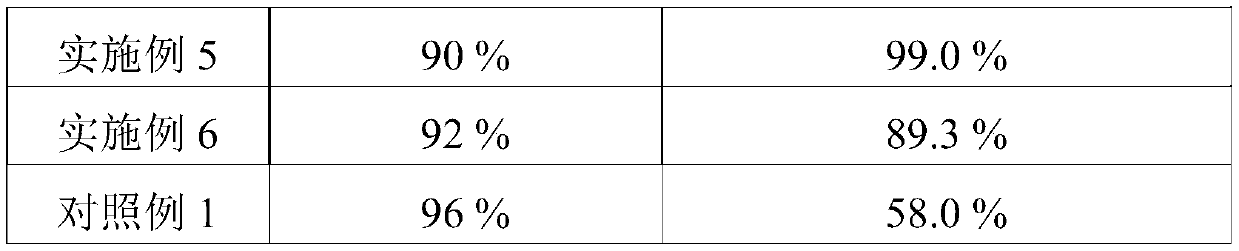

Embodiment 2

[0056] An antibacterial silver-plated fiber core-spun yarn is characterized in that it consists of a core yarn and a covered yarn.

[0057] The preparation method of the covered yarn: the cotton fiber and the silver-plated fiber are prepared through the conventional cleaning process, carding process, drawing process, grit process, spinning process, and winding process to prepare the covered yarn; wherein the cotton fiber 50wt%, and silver-coated fiber accounts for 50wt%.

[0058] The silver-coated fibers were prepared in Example 1.

[0059] The linear density of the covered yarn was 27.8 dtex.

[0060] The core yarn is spandex yarn, the spandex yarn is commercially available spandex yarn, and the linear density of the spandex yarn is 38 dtex.

[0061] The preparation method of antibacterial silver-plated fiber core-spun yarn:

[0062] The invention adopts the ZP-40 ring spinning frame (Shanghai Zhuopeng Science and Trade Co., Ltd.) to prepare the core-spun yarn. The spande...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com