Hollow type drive and control integrated intelligent modular joint

An intelligent module, hollow technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of low modularity, chaotic external wiring, large quality and volume, etc., and achieve high flexibility and compact structure design. , The effect of small transmission clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

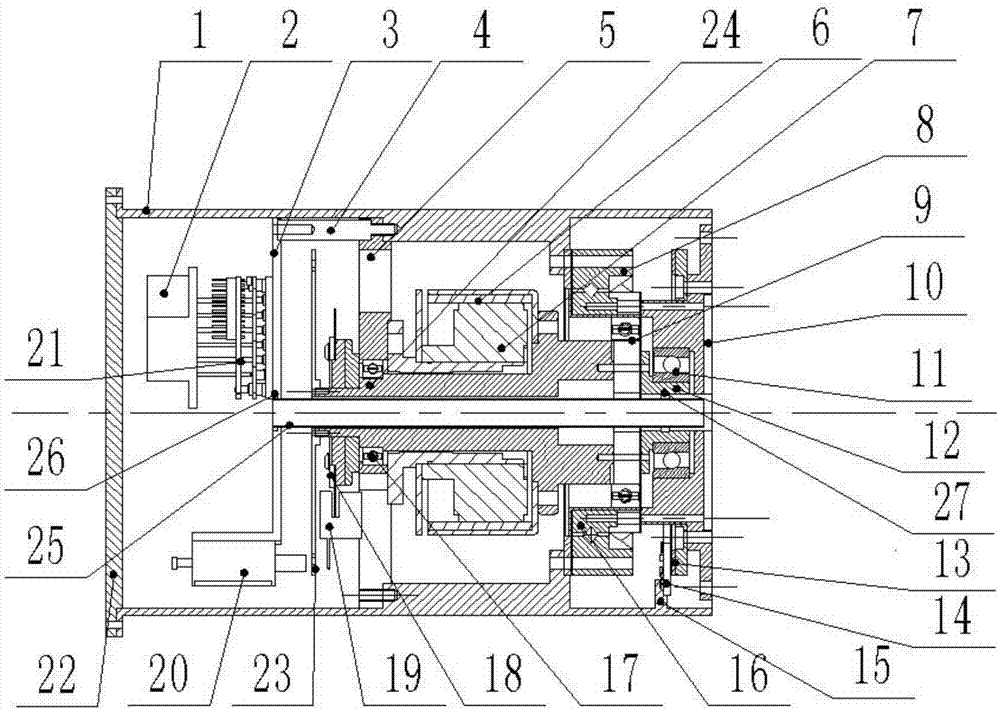

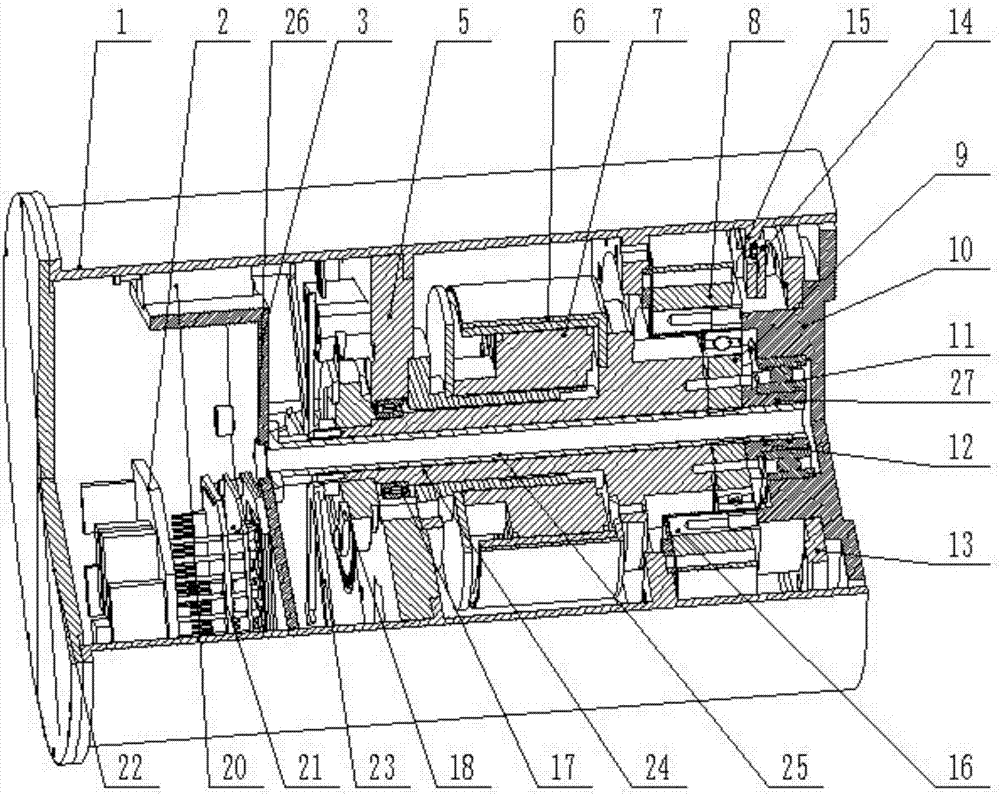

[0060] The overall size of the joint initially designed in this embodiment is 100mm in diameter, 145mm in length, and the maximum rated torque is 16.7N m. The outer diameter of the DC servo motor is 60mm, and the maximum rated torque is 319mN.m. The outer diameter of the harmonic reducer is is 80mm, the reduction ratio is 1:100, the maximum output torque of the harmonic reducer is 20N.m, and the length of the motor output shaft 24 is 73.5mm.

[0061] In this embodiment, the hollow drive-control integrated intelligent modular joint is small in size and light in weight, and the brake device dissipates heat quickly, and the brake device of this joint is directly connected to the output shaft of the motor without gear transmission. Transmission of large torque, the shell design of this joint is integrated, easy to process, good sealing, more modular characteristics, the harmonic reducer of this joint is directly connected with the output flange, which greatly reduces the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com