Pipeline basket type rotational flow filter

A cyclone filter and cyclone technology, applied in the direction of filtration separation, cyclone device, filtration loop, etc., can solve the problem of unsatisfactory separation effect of cyclone, achieve good filtration effect, prevent back mixing, and facilitate later stages The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following specific examples illustrate the implementation of the present invention. Those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

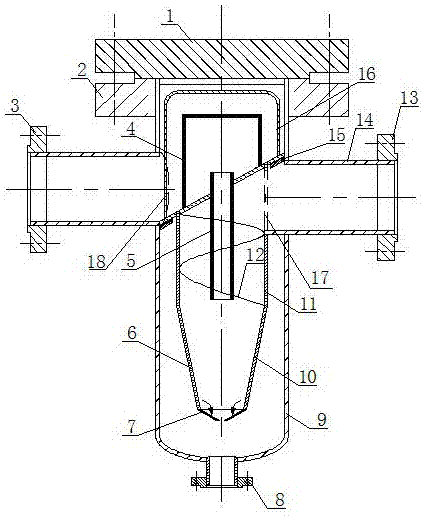

[0017] Such as figure 1 Shown is a schematic diagram of the overall structure of the present invention. A pipe basket cyclone filter includes a blind plate 1, a barrel 9, a stainless steel tube 14, a cyclone 6, and a sewage outlet 8. The stainless steel pipe 14 passes through the barrel 9 transversely. , The stainless steel tube 14 communicates with the cylinder body 9, the stainless steel tube 14 and the cylinder body 9 form a cross structure, the upper end of the cylinder body 9 is fixedly connected with the blind plate 1, and the blind plate 1 is connected to the upper end of the cylinder body 9 through the flange 2 For a fixed connection, a sewage outlet 8 is fixedly installed at the lower end of the cylinder 9, the cyclone 6 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com