Corn reaping and threshing device

A technology of corn and threshing rollers, which is applied in the direction of harvesters, cutters, loaders, etc., can solve the problems of high energy consumption, reduce the efficiency of harvesting and detachment, and achieve the effects of safe operation, good crushing effect, and small harvest loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

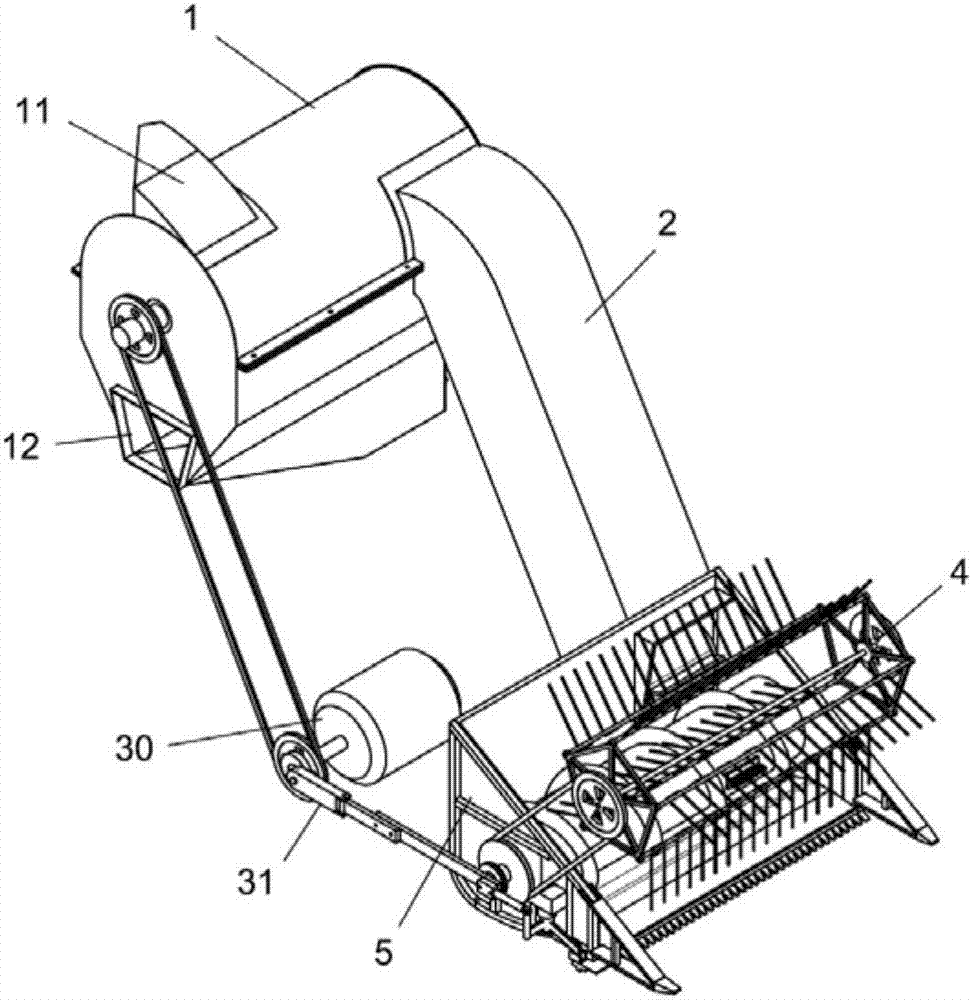

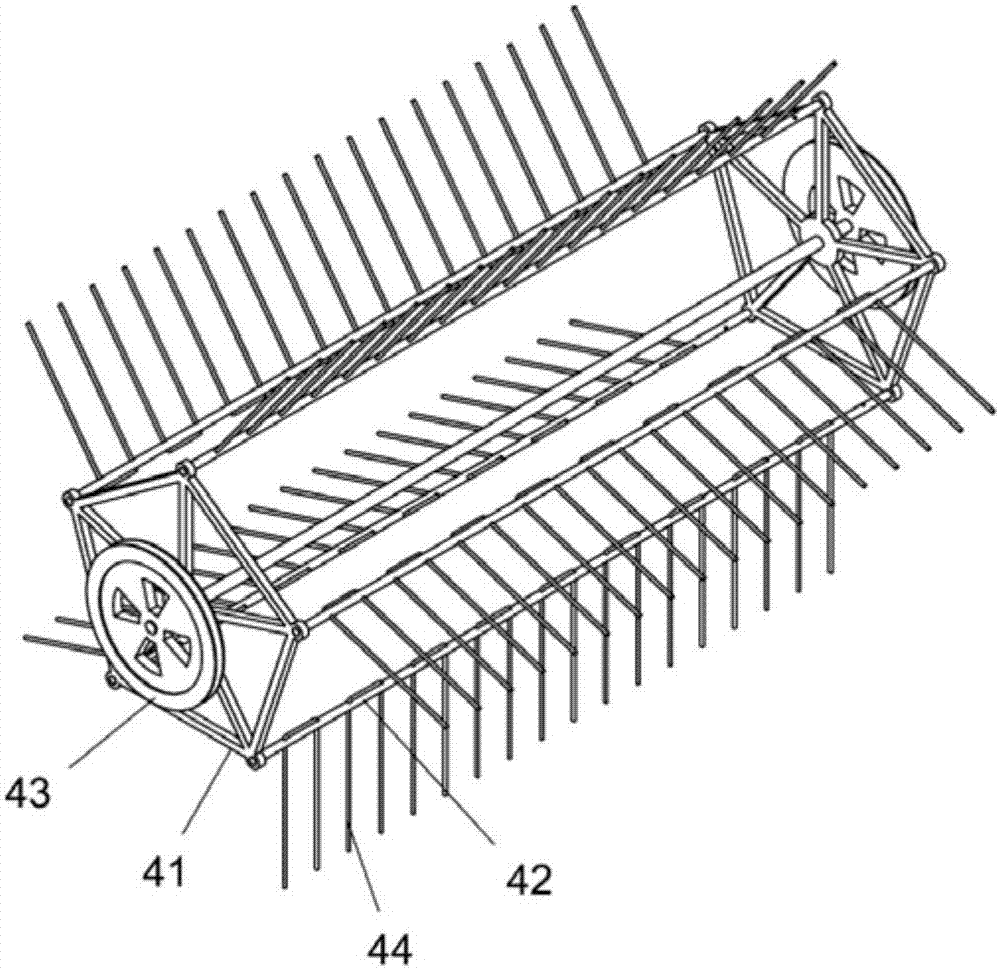

[0018] Such as Figure 1-4 Shown, a kind of corn harvesting granulating device, it comprises cutting guide ear unit 5, and cutting guide ear unit 5 comprises cutting guide ear frame 51, is provided with guide ear mouth 510 at the rear portion of cutting guide ear frame 51, and cutting guide ear The middle part of the frame 51 is equipped with a spiral plucking ear roller 52 through a bearing, and a spiral guide plate 53 is welded on the spiral plucking ear roller 52. The bottom surface end of the cutting ear guide frame 51 is fixedly provided with a cutting tooth 56, and one side of the cutting ear guide frame 51 is fixed. There is a mounting plate 511, the lower part of the mounting plate 511 is equipped with a transmission folding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com