Auxiliary drive capacitor protection structure of electric vehicle all-in-one controller

A technology for auxiliary drive and electric vehicles, applied in the direction of printed circuits, electrical components, printed circuits, etc. connected with non-printed electrical components, can solve problems such as vibration and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

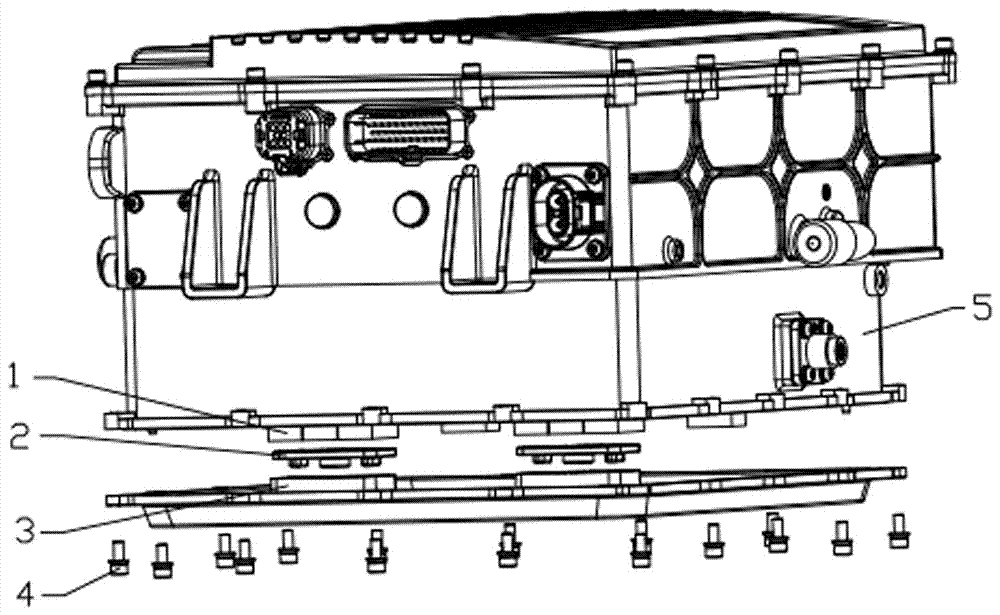

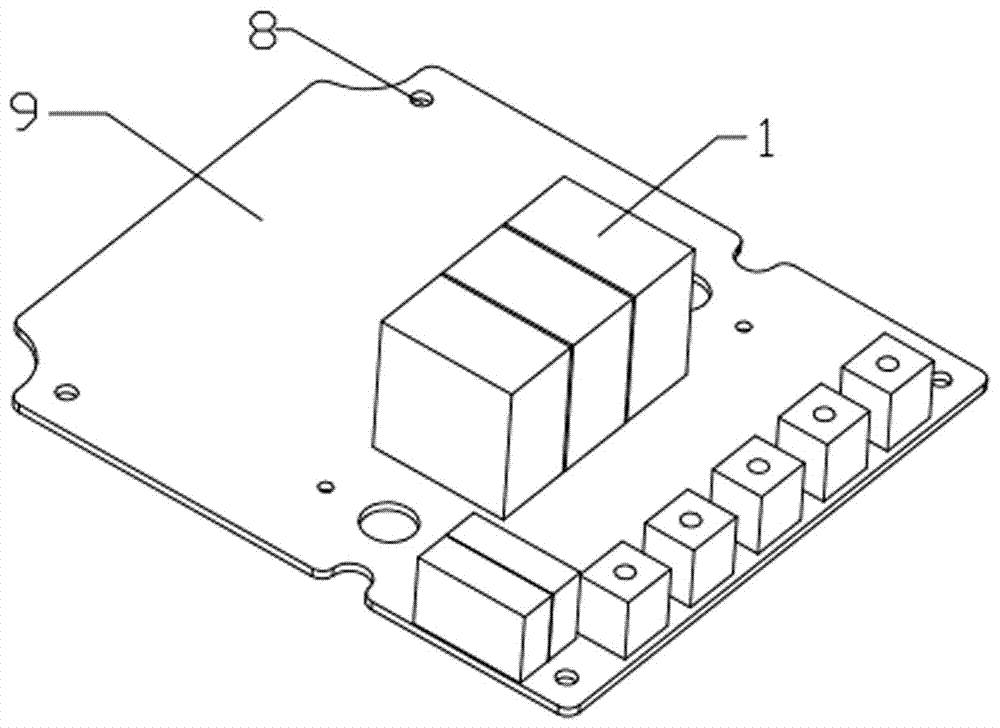

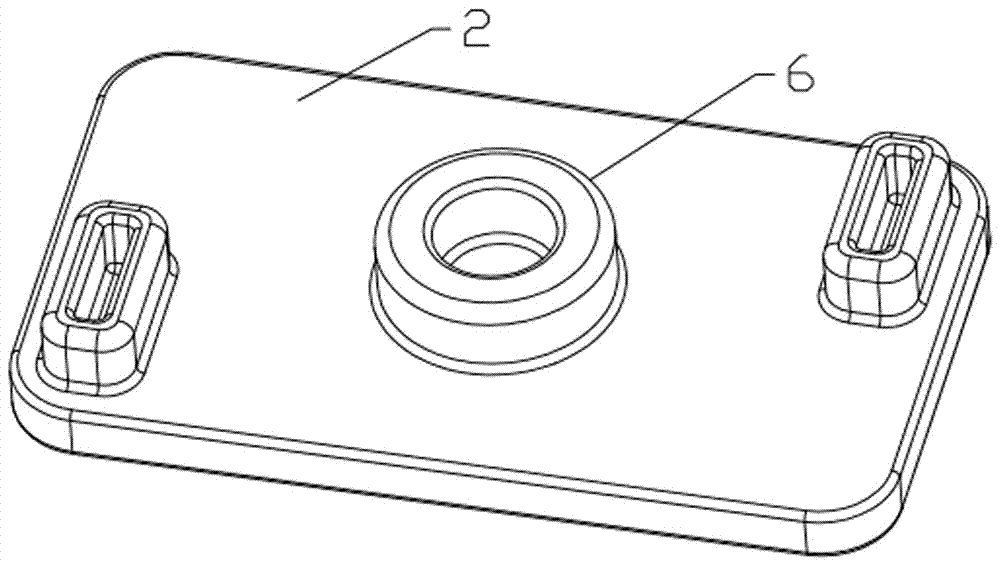

[0019] Example: such as Figure 1-4 As shown, an electric vehicle multi-in-one controller auxiliary driving capacitor protection structure of the present invention includes two capacitors 1, and the capacitors 1 are all welded on the PCB board 9, and several screw holes 8 are provided around the PCB board 9, The PCB boards 9 are all fixed on the box body 5 by screws 4; a base plate 3 is provided below the capacitor 1, and two bosses 6 are arranged on the top of the base plate 3, so that the shock absorbing pad 2 is fixed on the bosses 6, so that The shock-absorbing pad 2 between the bottom plate 3 and the capacitor 1 reduces the vibration transmitted to the capacitor 1, so that the welding between the capacitor 1 and the PCB board 9 will not be affected by the vibration, and the pins of the capacitor will not be damaged. Solder breakage occurs, and then the service life of the controller is increased; a shock pad 2 is placed on the top of the boss 6, and the front of the shock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com