Template accurate sample turning and batching system based on BIM

A batching system and template technology, which is applied in the field of template accurate batching system, can solve problems such as size deviation, and achieve the effects of reducing template deviation, improving use efficiency, and facilitating classification and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further illustrated below by specific examples.

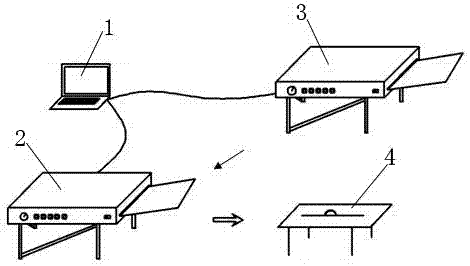

[0017] Such as figure 1 , figure 2 The shown BIM model-based template accurate batching system, the system consists of a PC terminal 1, template raw material automatic branch line inkjet printer 2, template automatic slag cleaning size scanning inkjet printer 3, and cutting table 4;

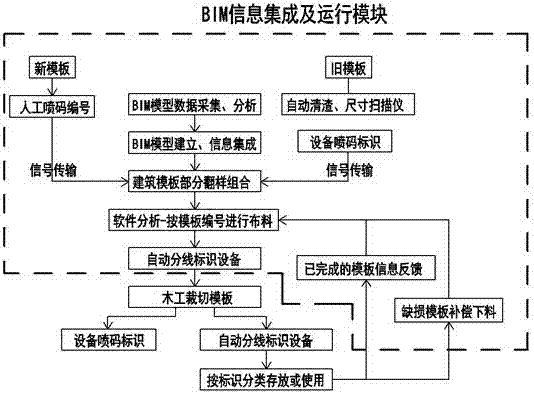

[0018] Collect the design parameters and data of the building, establish a BIM model for data integration processing, information import, analysis and export, analyze the whole process and the whole building, calculate the basic parameters of the template, and automatically divide the template into blocks Ingredients, and data feedback on the processed parts at the same time;

[0019] After the template raw materials are prepared, firstly, the cleaning and marking equipment is used for automatic cleaning and coding, and the coding information is automatically fed back to the BIM model system to realize the unique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com