Supporting base structure

A technology of support seat and support frame, applied in mechanical equipment, fixtures, etc., can solve the problems of poor mechanical strength, damage, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

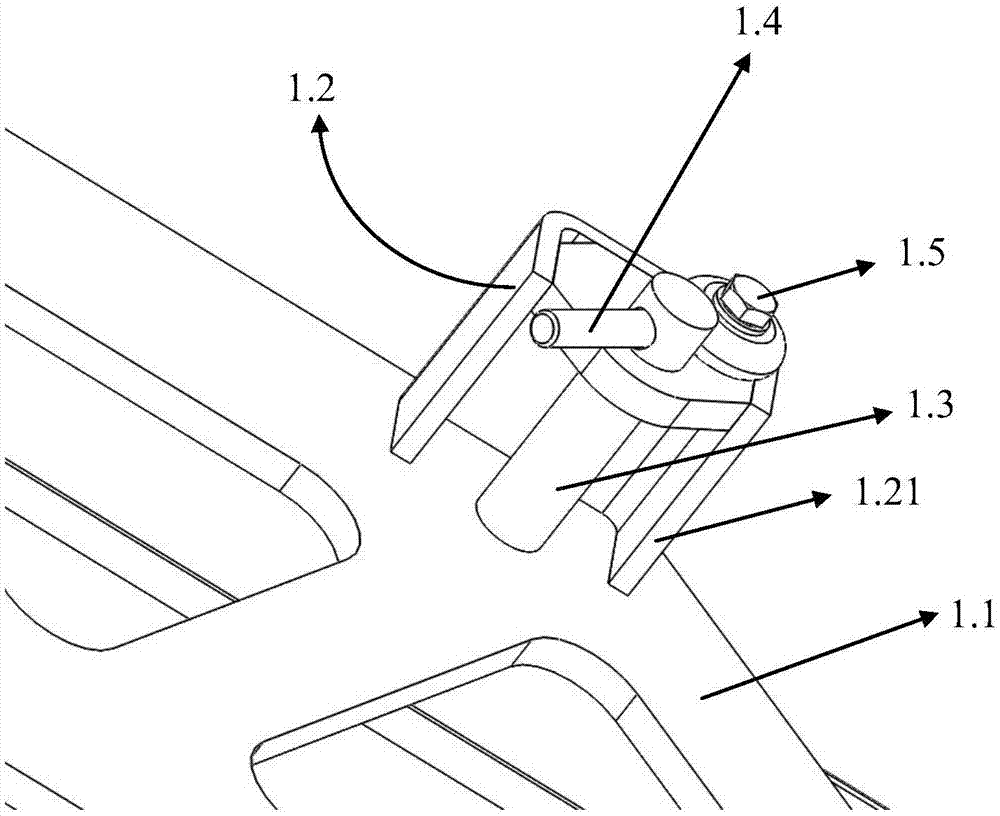

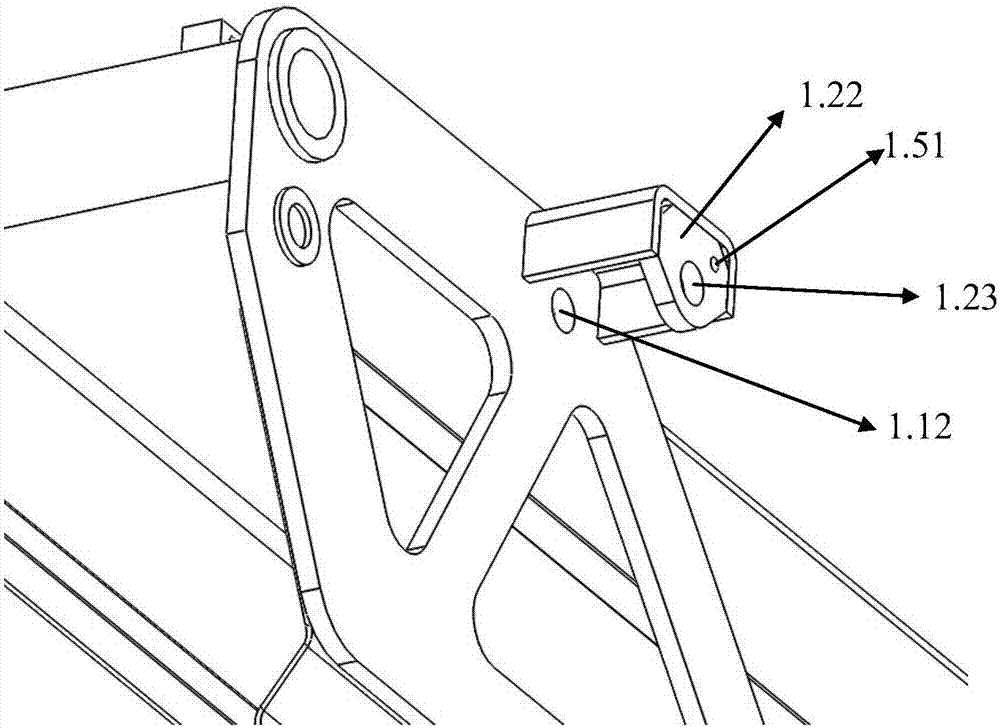

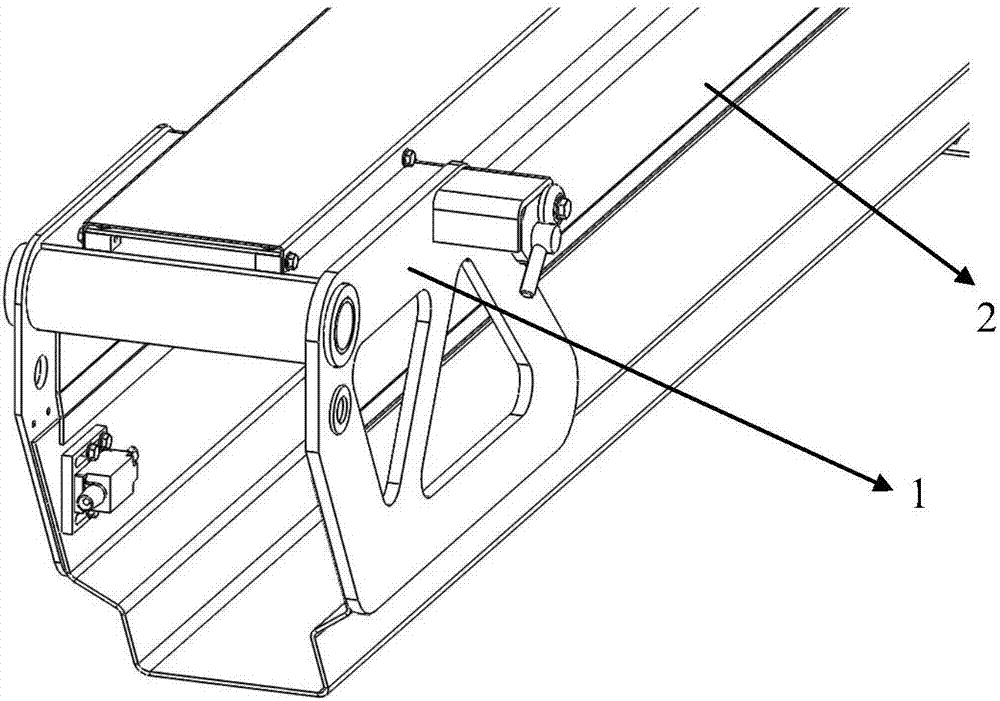

[0018] As shown in the figure, a supporting base structure 1 is used to fix the to-be-connected mechanism 2 on the supporting base structure 1. It includes a support frame 1.1 and a fixing seat 1.2 arranged on one side of the support frame. The support frame 1.1 includes at least a fixed side wall 1.11, and the fixed side wall has a through fixing hole 1.12; the fixing seat 1.2 has a connecting portion 1.21 and a limit plate 1.22 , The connecting portion 1.21 has three connecting surfaces, all of which are connected to the fixed side wall 1.11 and the limit plate 1.22. The limit plate 1.22 has a through fixing hole 1.23, and the fixing hole 2.1 on the connecting mechanism 2 is to be fixed. The fixing holes 1.12 on the side wall and the fixing holes 1.23 on the limiting plate are distributed in a straight line, and the fixing shaft 1.3 is inserted into the three fixing holes for fixing.

[0019] The fixed shaft 1.3 has a limit hole that allows the limit shaft 1.4 to pass through, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com