Coal mine rock tunnel three-axis slotting punching rock breaker

A technology of rock breaking device and undercutting chisel, which is applied to driving devices for drilling in wellbore, drilling equipment, drilling with liquid/gas jet, etc. Continuity, low drilling efficiency and other problems, to achieve the effect of reducing construction costs, improving blasting procedures, and reducing drilling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

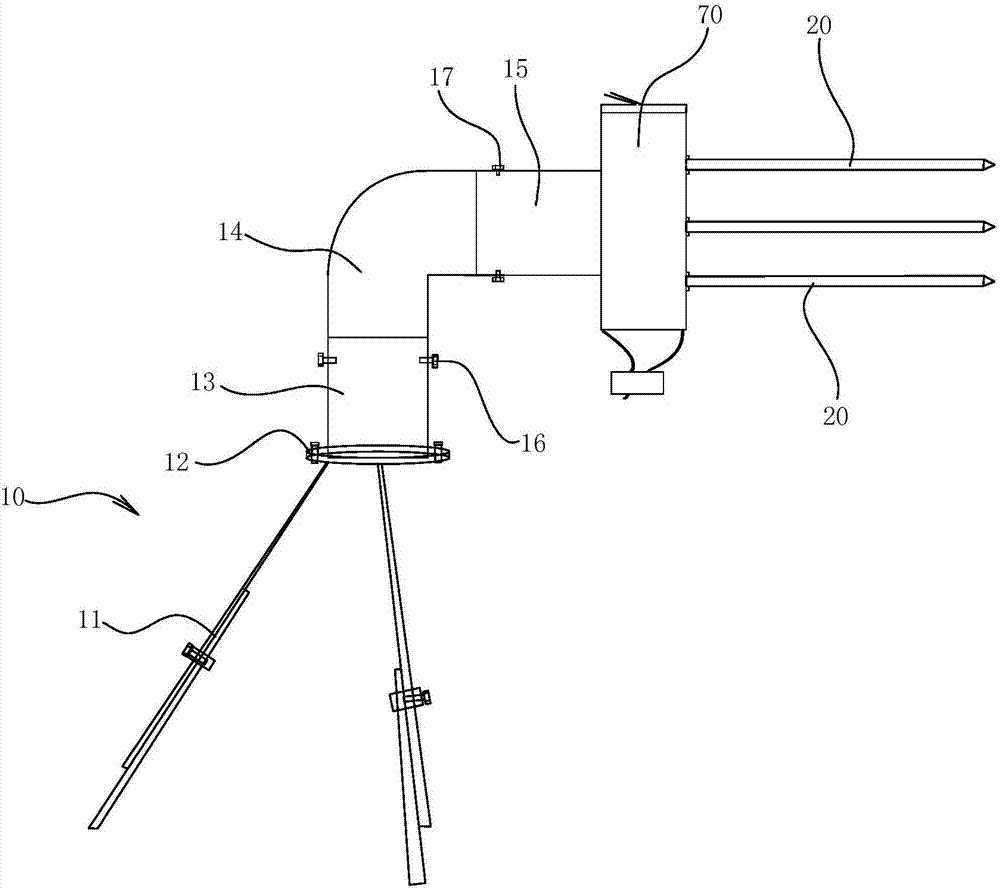

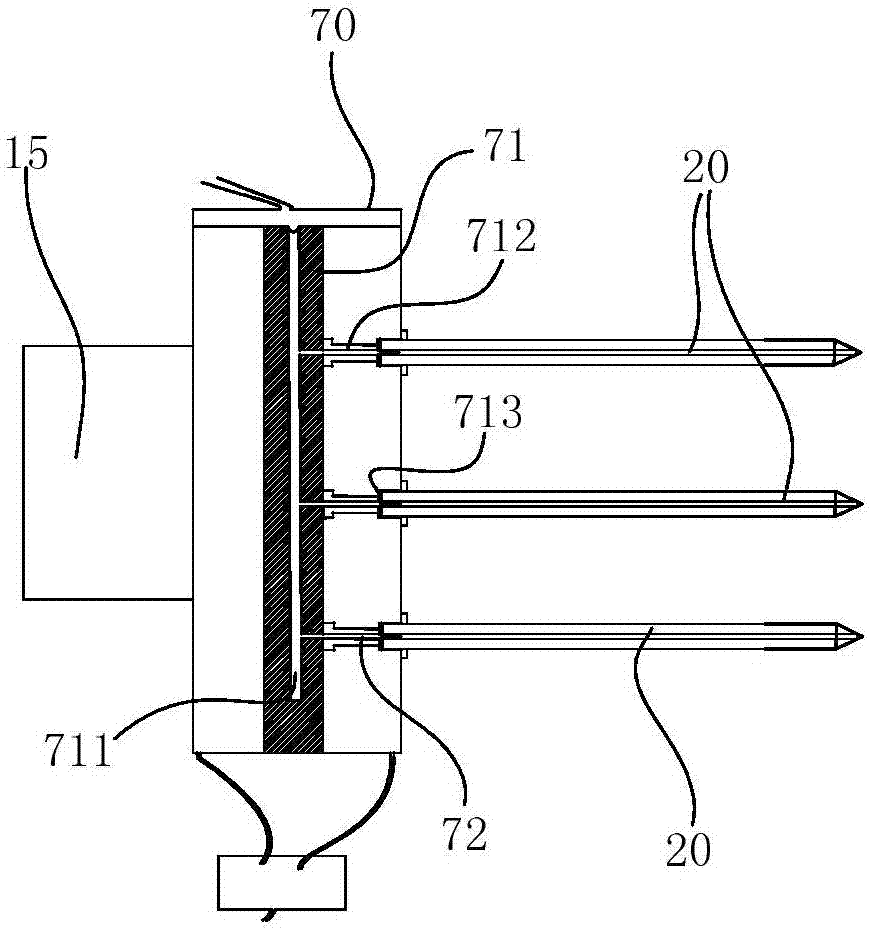

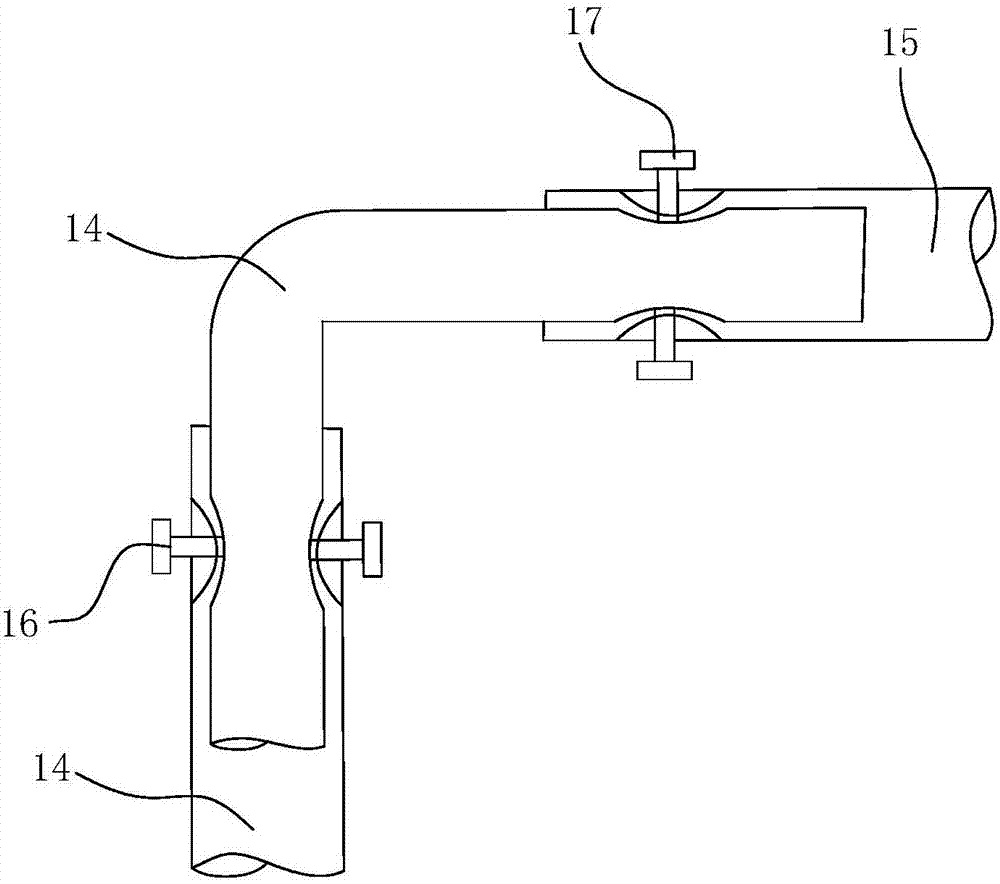

[0020] combine Figure 1 to Figure 4 , the present invention is further described:

[0021] Coal mine rock roadway three-axis cutting drilling hole rock breaking device, including the drill rod 20 arranged on the adjustment bracket 10, the length direction of the drill rod 20 is horizontal and one end is connected with the horizontal drive mechanism, the drill rod 20 is located on the adjustment bracket 10 is provided with a plurality of parallel intervals, and the horizontal drive mechanism drives the drill rod 20 to move horizontally back and forth and implement the drilling operation. The spatial position of the drill rod 20 located on the adjustment bracket 10 is adjustable;

[0022] combine figure 1 As shown, in the actual blasting, firstly, the device is used to cut and drill holes in the area to be blasted according to the design drawings. The cutting and drilling mechanism itself is arranged on the adjustment bracket 10, and the spatial position of the adjustment brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com