A slab-column structure assembly system and its floor prefabricated components

A technology of prefabricated components and slab-column structures, which is applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of high technical requirements for construction personnel, a large number of supports and formwork installations, and non-structural forms, so as to reduce construction difficulty and save Effects of building materials and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

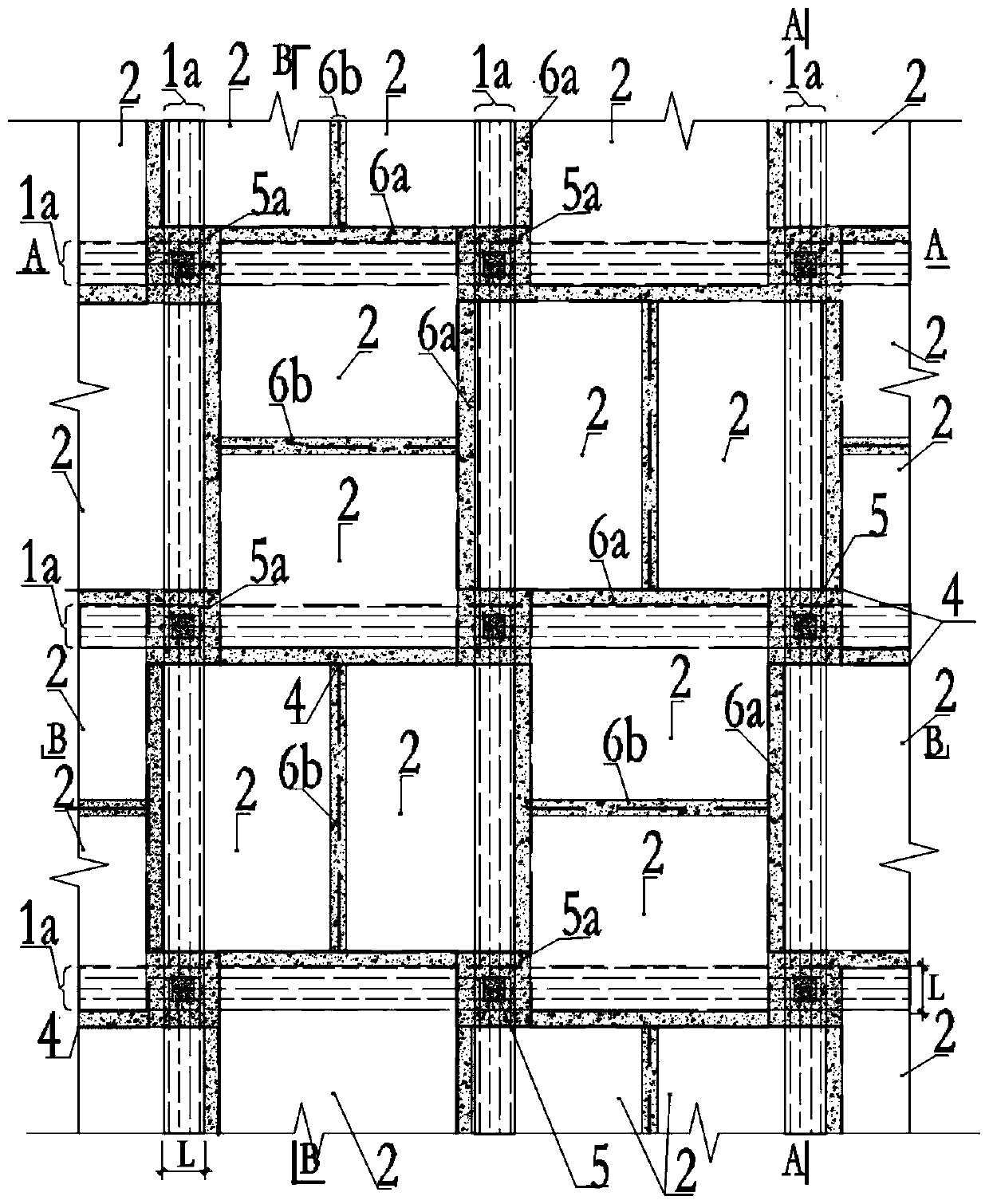

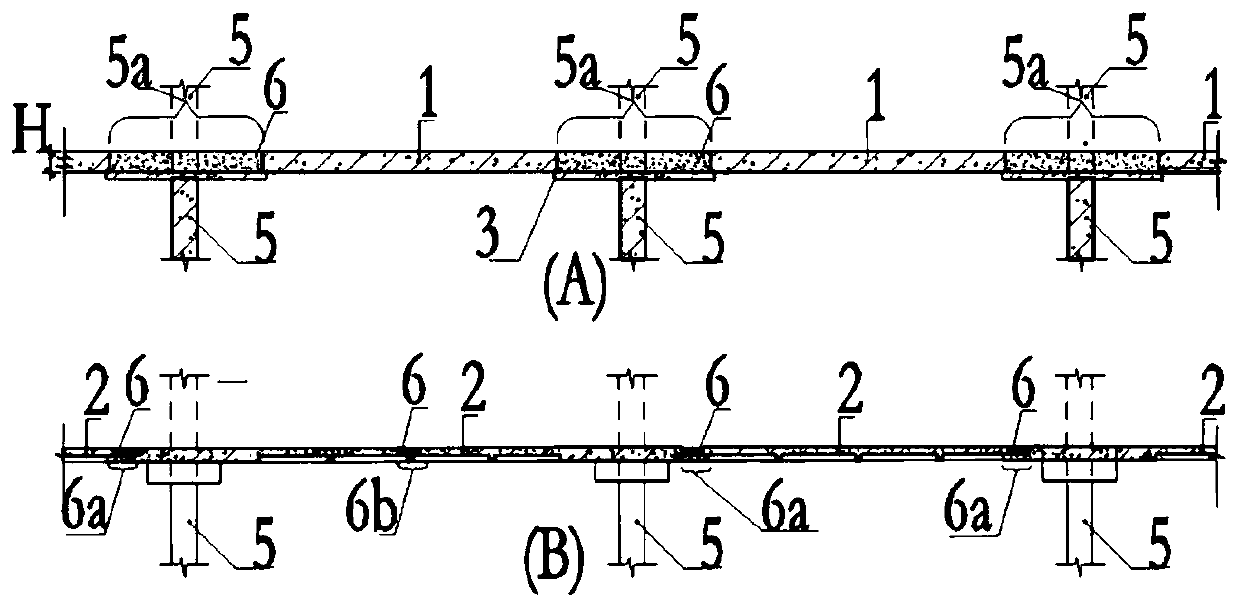

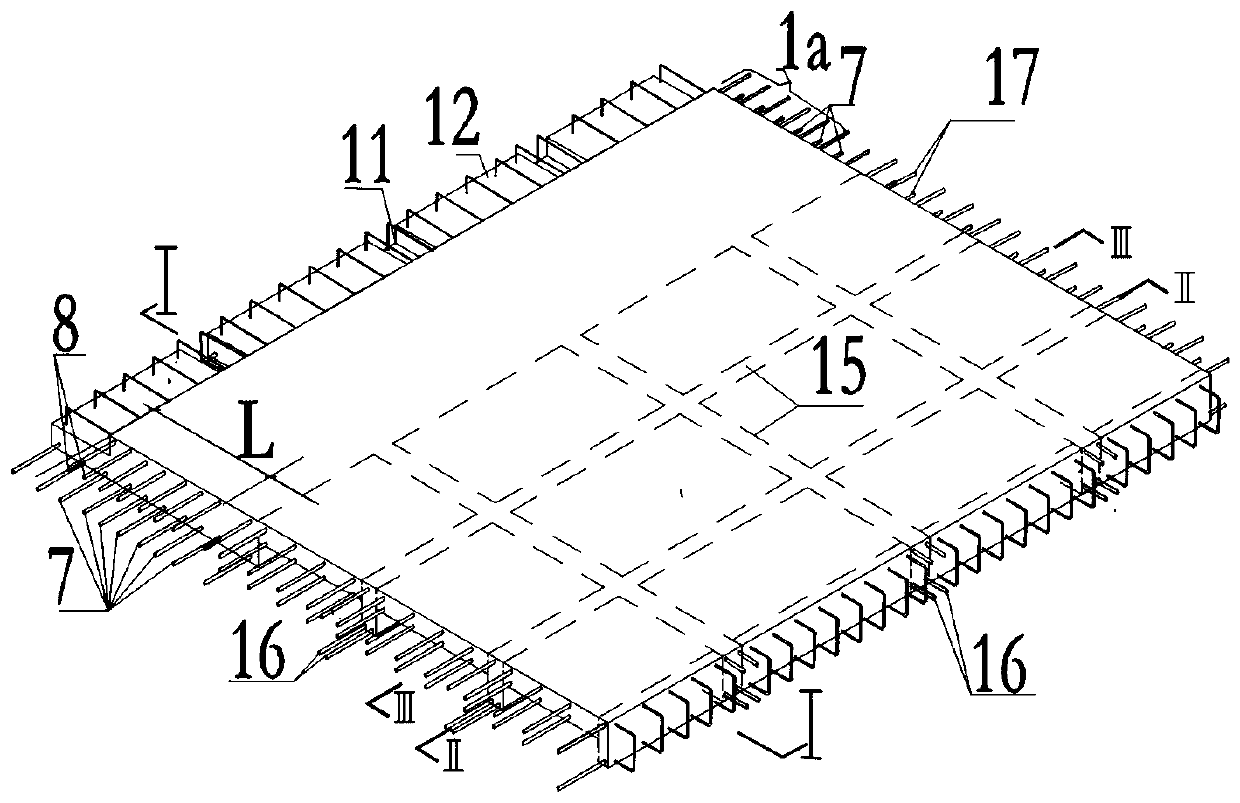

[0052] Such as Figure 1-23 As shown, the slab-column structure assembly system includes columns 5, prefabricated column caps or pallets 3, floor prefabricated components, connecting nodes (5a, 6a and 6b) and supplementary reinforcement. The prefabricated floor slab consists of a part 1 with a column cap connecting plate and a part 2 without a column cap connecting plate, and the form or thickness of the part 1 containing a column cap connecting plate and the part 2 without a column cap connecting plate cannot be completely same, (and the slab prefabricated elements are similarly shaped elements). The prefabricated column cap or supporting plate 3 is inserted into the top of the column 5, and the end of the connecting plate belt part 1 including the column cap in the length direction of the prefabricated floor slab is la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com