Finishing equipment for adjusting leaflets

A technology for equipment and adjustment components, applied in thin material handling, stack receiving device, transportation and packaging, etc., can solve the problems of reducing work efficiency, increasing time cost, spending extra time, etc., to improve work efficiency and reduce finishing time, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

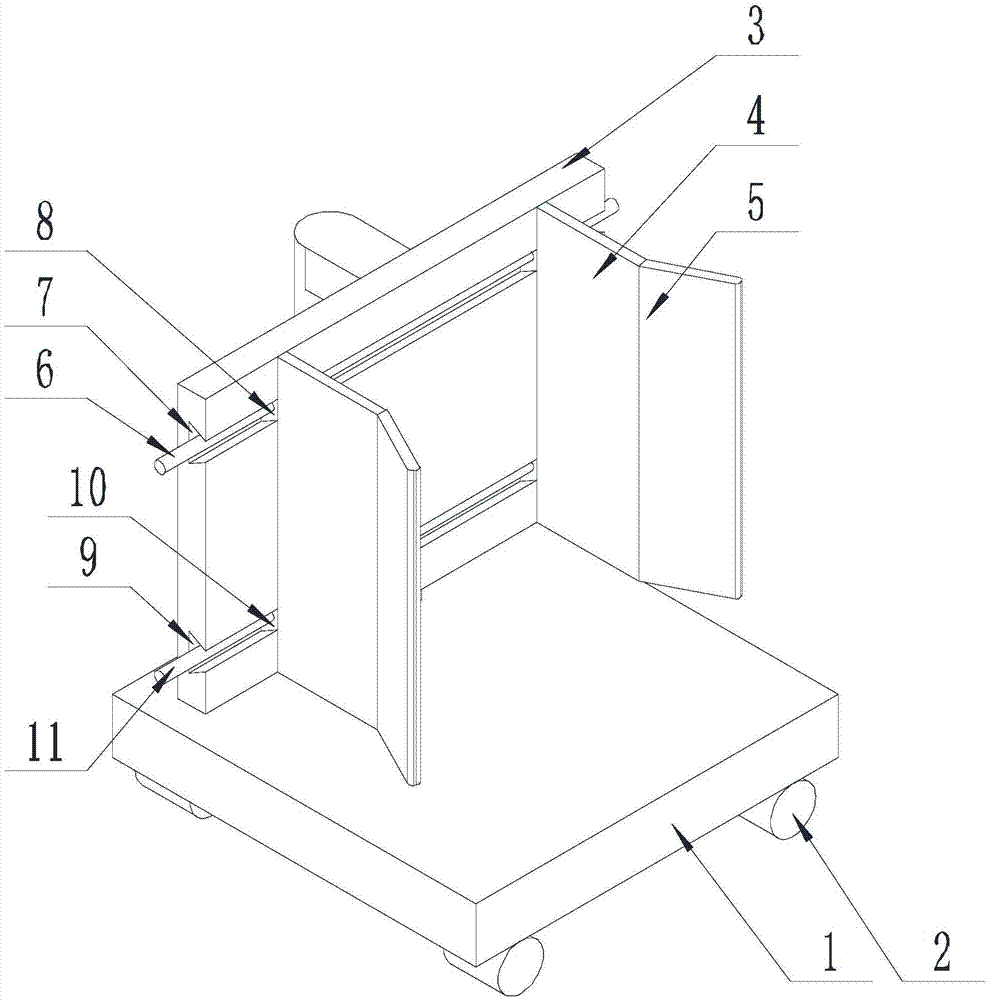

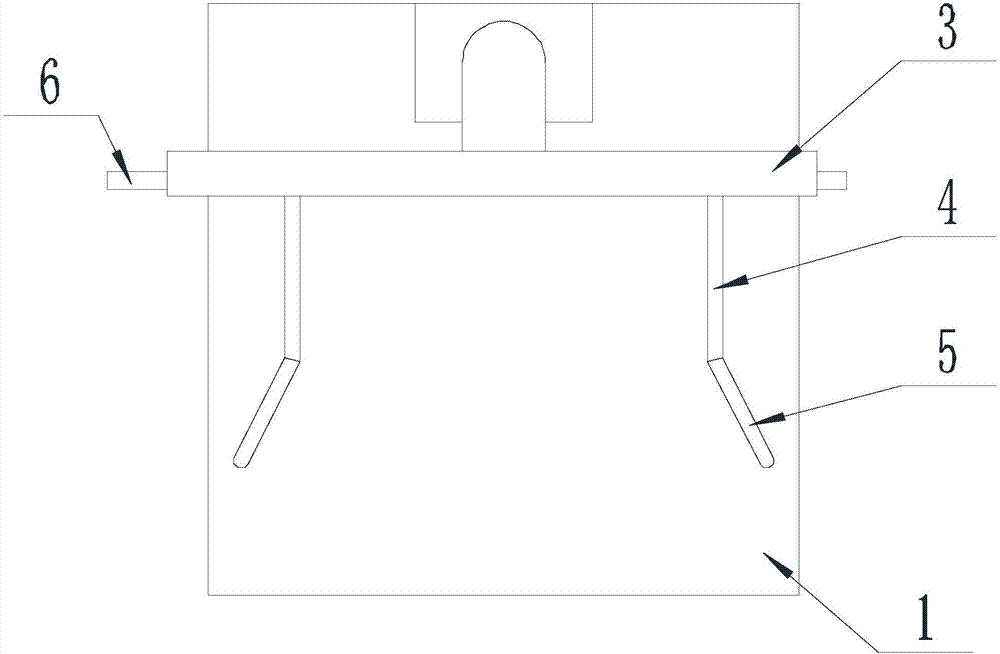

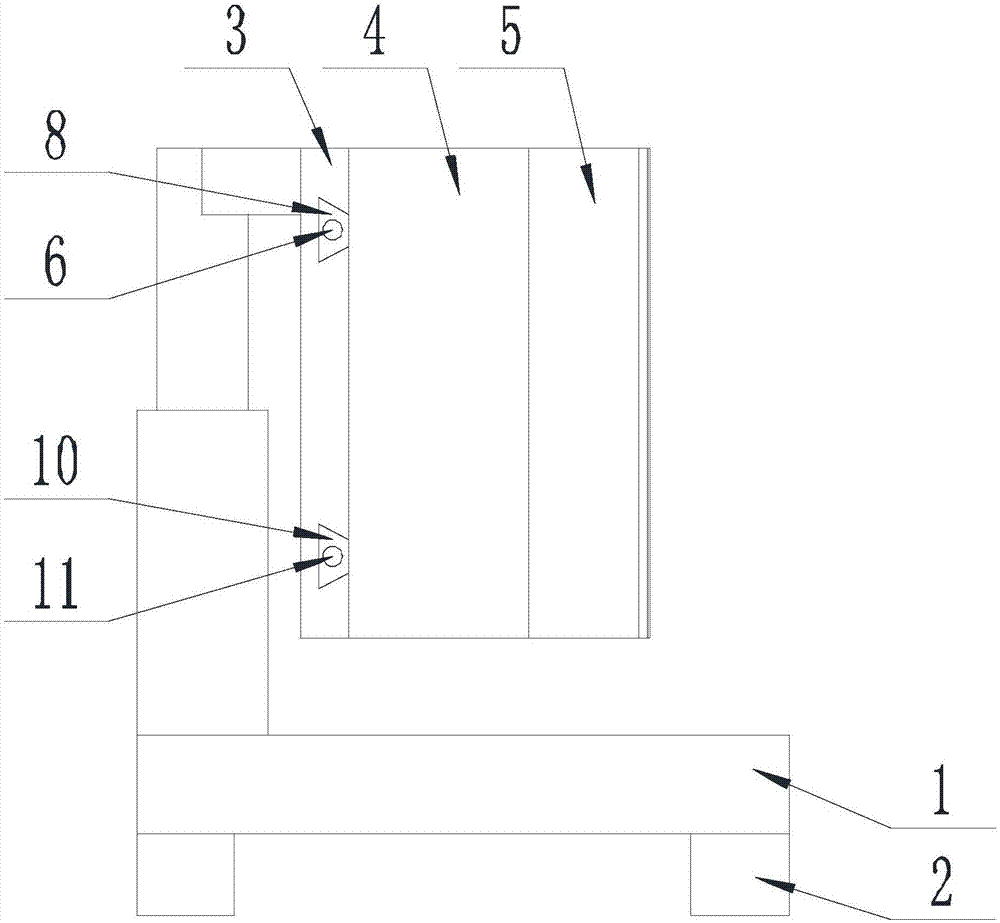

[0036] like Figure 1-Figure 3 As shown, the present invention is used to adjust the sorting equipment of leaflets, which includes a bearing plate 1 provided with rollers 2 on the bottom surface, and a driving mechanism and an adjustment assembly connected in sequence are arranged on the upper surface of the bearing plate 1, and the driving mechanism The drive adjustment assembly is away from or close to the carrier plate 1. The adjustment assembly includes a positioning plate 3 connected in sequence, a driving device and a pair of moving plates 4. The driving device drives the moving plates 4 to approach or move away from each other, and the movement of the moving plate 4 The rails are parallel to the carrying plate 1 and the positioning plate 3 at the same time.

[0037] Start the driving mechanism according to the required height, so that the adjustment components are located at a suitable height; then start the driving device, so that the distance between the moving boards...

Embodiment 2

[0039] The present invention is based on embodiment 1, and the present invention is further described.

[0040] like Figure 1-Figure 3 As shown, the present invention is used to adjust the sorting equipment of leaflets. On the end of the moving plate 4 away from the positioning plate 3, a guide plate 5 is provided. The guide plate 5 is perpendicular to the bearing plate 1, and between the guide plates 5 The distance between them gradually increases as the guide plate 5 moves away from the moving plate 4 .

[0041] The setting of guide plate 5 has improved the smoothness of placing advertisement sheet.

[0042]Further, the driving device includes a screw rod 6 and a motor connected in sequence, and a driving groove 7 is arranged on the surface of the positioning plate 3 close to the moving plate 4, and the axis of the driving groove 7 is parallel to the moving track of the moving plate 4 , on the moving plate 4, one end close to the positioning plate 3 is provided with a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com