Goods storage system and shared bicycle storage system using system

A storage and retrieval system and cargo technology, applied in the field of cargo storage and retrieval systems and shared vehicle storage and retrieval systems, can solve the problems of expired and damaged underlying cargo, large space for loose cargo, and easy deformation and damage in stacking, so as to prevent deterioration and damage. , saving floor space and preventing shaking and tremor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

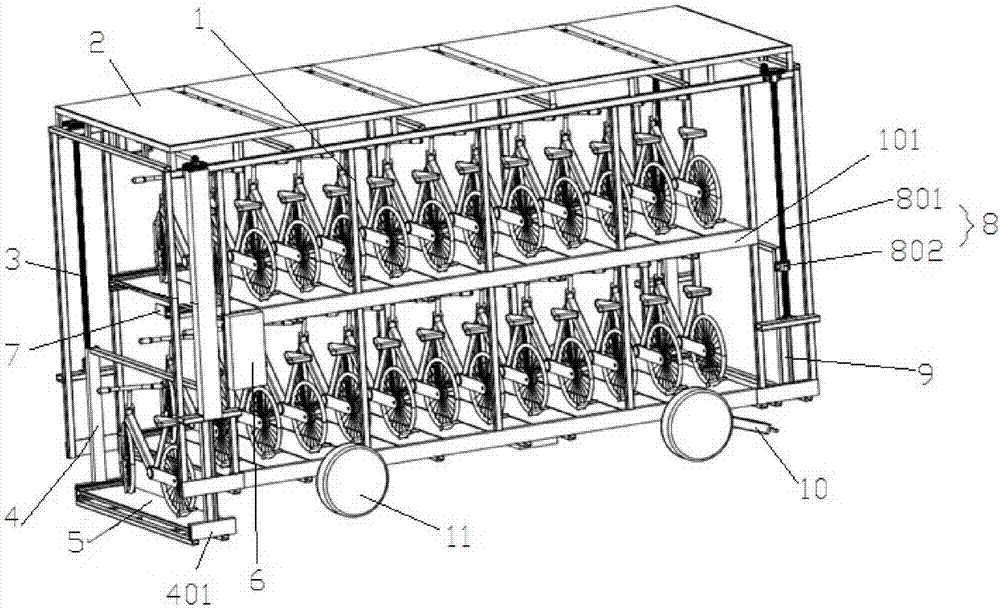

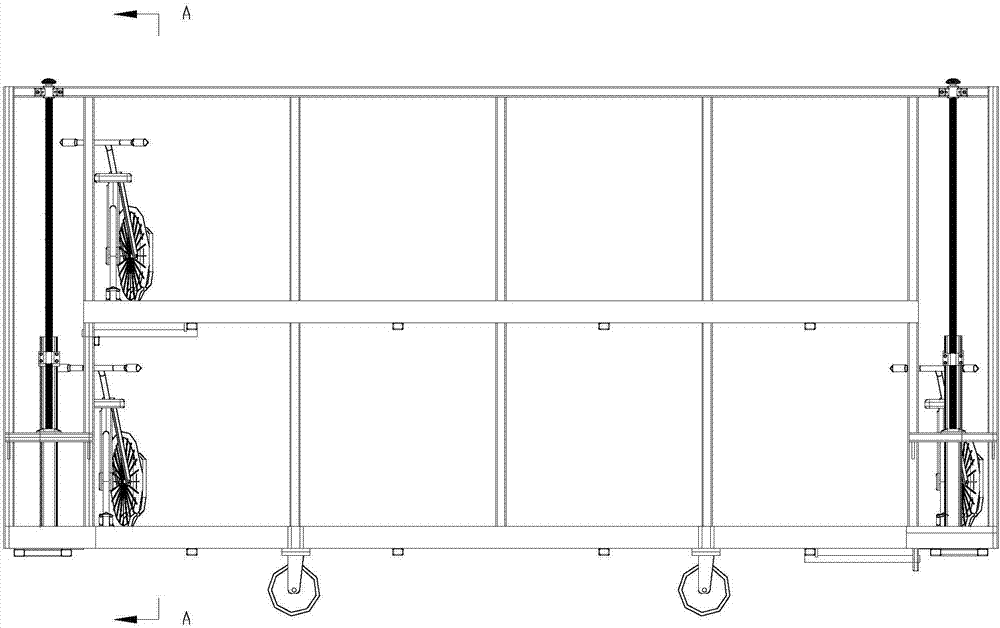

[0052] Such as Figure 1~5 As shown, the present embodiment is a cargo access system, comprising: a frame body 1, a first lifting mechanism 3, a second lifting mechanism 8, a first lifting frame body 4, a second lifting frame body 1, at least two traction device 7 and a plurality of carrier plates 5;

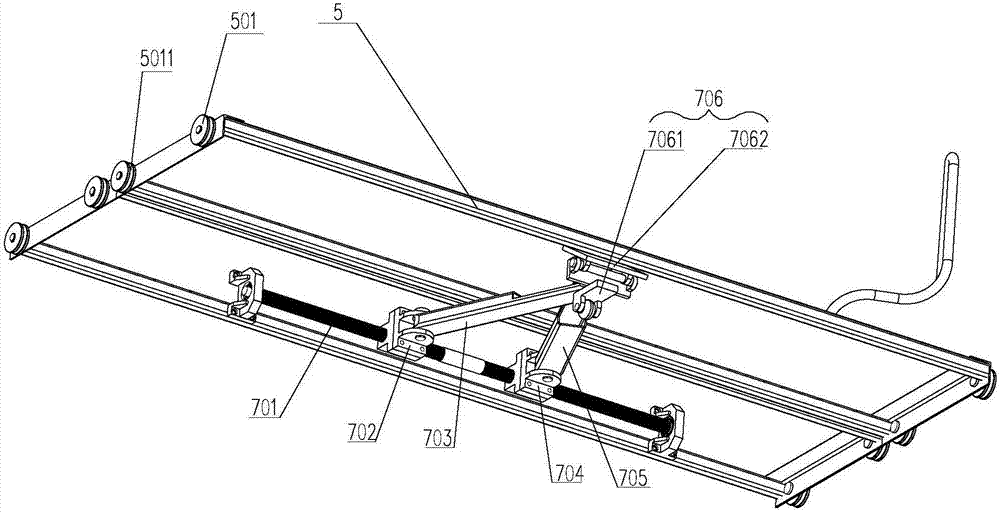

[0053] The frame body 1 is provided with at least two guide bearing parts linearly arranged along the height direction. The guide bearing parts include two horizontal brackets 101 fixedly installed on the frame body 1 and at least one horizontal linear moving guide part. The brackets 101 are respectively arranged on the front and rear sides of the frame body 1. The two horizontal brackets 101 and at least one horizontal linear movement guide part are all parallel to each other and extend linearly along the left and right direction of the frame body 1. All the horizontal linear movement guide parts and The lengths of all horizontal brackets 101 are equal and are integer multiple...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is that the horizontal linear movement guide part and the lifting horizontal linear movement guide part in this embodiment are arranged between the front and rear vertical plates 1012 of the two horizontal brackets 101 on the same cargo storage layer The linear movement track of (such as Figure 6 shown), the guide module on the loading plate 5 is directly served by the rotating shafts of the rollers 501 arranged on both sides of the loading plate 5 , and a gap is formed between the vertical plates on both sides and the shaft ends of the roller rotating shafts on both sides of the loading plate 5 . The horizontal linear movement pair, the loading plate 5 can advance along the track between the two vertical plates in a straight line under the traction of the traction device 7 .

Embodiment 3

[0074] The difference between this embodiment and Embodiment 1 is that the first lifting mechanism and the second lifting mechanism in this embodiment are two winches arranged on the front and rear sides of the frame body, and the traction ropes of the winches go around the fixed The pulleys are respectively connected with the first lifting frame body or the second lifting frame body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com