A nanocomposite photocatalytic film material and its preparation method

A photocatalytic thin film and nanocomposite technology, applied in the field of photocatalysis, can solve problems such as poor recycling rate, increased water treatment cost, and difficult recycling, and achieve the effects of low cost, easy control, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

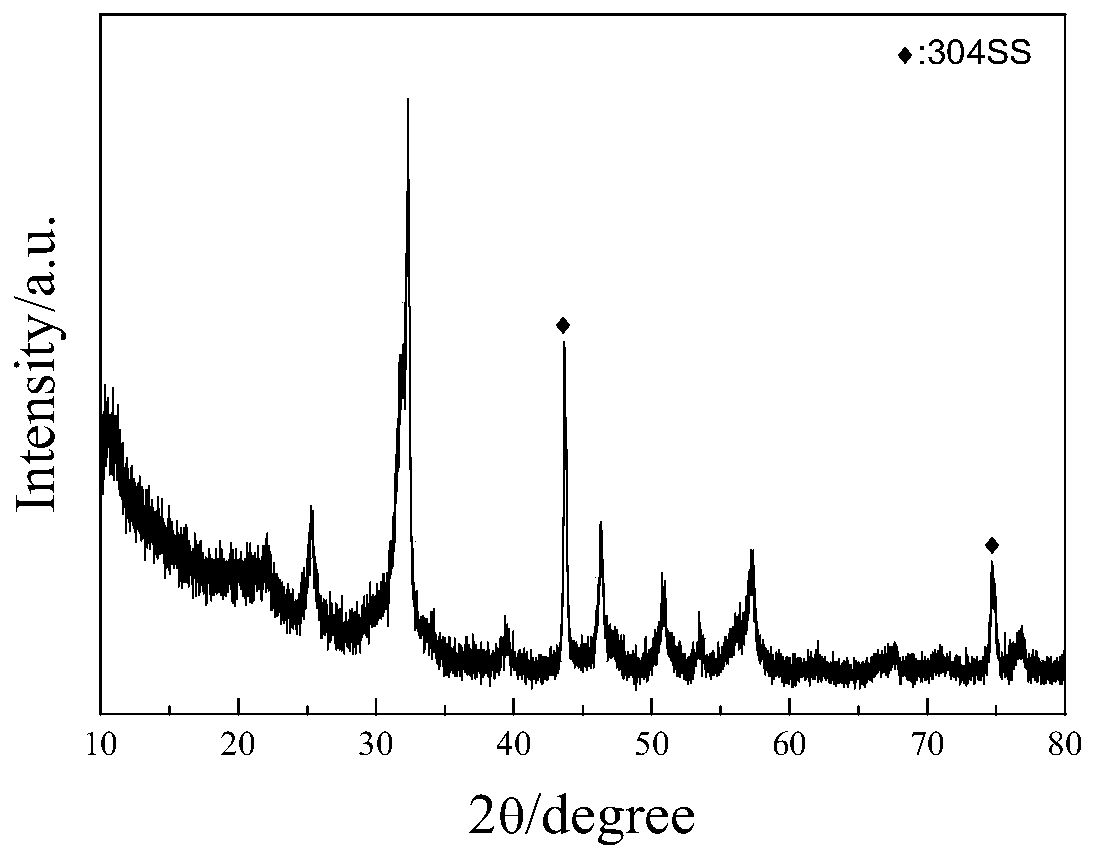

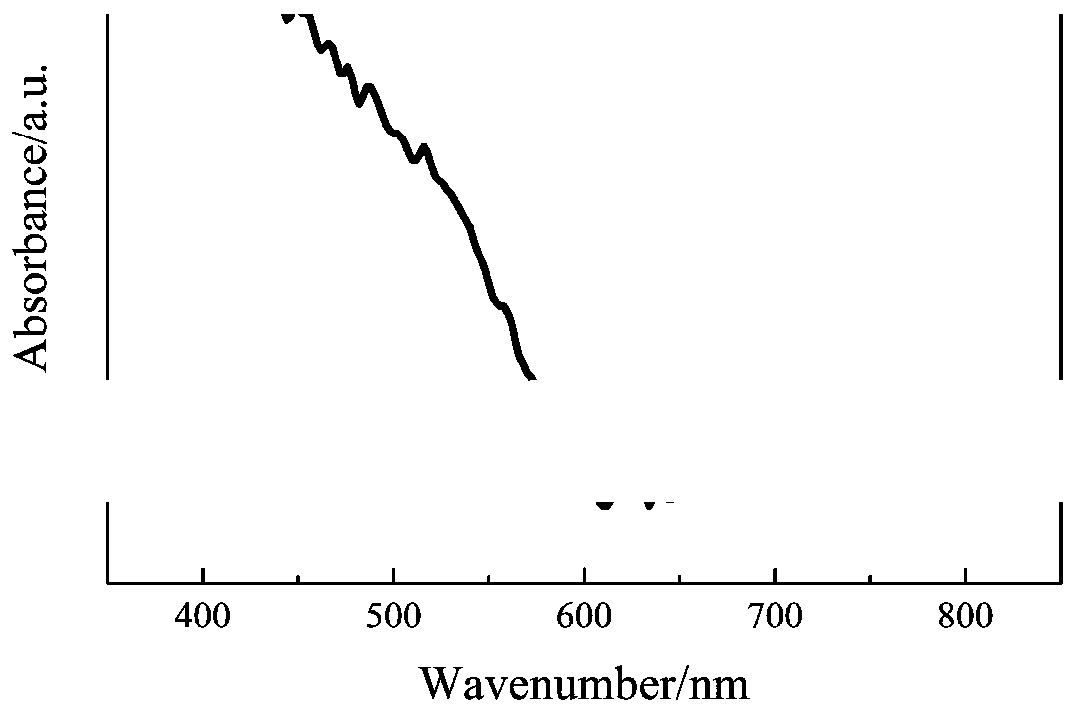

[0025] Example 1: Preparation method of BiOI / BiOBr nano composite photocatalytic film material with sheet-like layered structure

[0026] Firstly, a BiOI precursor film material with a sheet-like layered structure was prepared on the surface of the stainless steel substrate by in-situ growth under hydrothermal conditions. Weigh 8mmol Bi(NO 3 ) 3 ·5H 2 O and 0.1g PVP were added to 70mL ethylene glycol, ultrasonically dispersed for 30min, 8mmol KI was weighed and dissolved in 10mL water, and then the two solutions were mixed uniformly and transferred to a 100mL reactor. The pre-pretreated stainless steel mesh is immersed in the above mixed solution. Then the reaction kettle was heated to 140°C, and the reaction time was 4h. After the completion of the reaction, the stainless steel mesh was taken out, washed with absolute ethanol and distilled water in turn, and finally placed in a drying oven at 60°C for 6 hours. Weigh 0.48mmol of tetrabutylammonium bromide into 80mL of water, ma...

Embodiment 2

[0029] Example 2: Preparation method of BiOI / BiOBr nano composite photocatalytic film material with sheet-like layered structure

[0030] Firstly, a BiOI precursor film material with a sheet-like layered structure was prepared on the surface of the stainless steel substrate by in-situ growth under hydrothermal conditions. Weigh 4mmol Bi(NO 3 ) 3 ·5H 2 O and 0.2g PVP were added to 70mL ethylene glycol, ultrasonically dispersed for 30min, 4mmol KI was weighed and dissolved in 10mL water, then the two solutions were mixed uniformly and transferred to a 100mL reactor. The pre-pretreated stainless steel mesh is immersed in the above mixed solution. Then the reaction kettle was heated to 160°C, and the reaction time was 8h. After the completion of the reaction, the stainless steel mesh was taken out, washed with absolute ethanol and distilled water in turn, and finally placed in a drying oven at 60°C for 6 hours. Weigh 0.80mmol of tetrabutylammonium bromide and add it to 80mL of wate...

Embodiment 3

[0031] Example 3: Preparation method of BiOI / BiOBr nanocomposite photocatalytic film material with sheet-like layered structure

[0032] Firstly, a BiOI precursor film material with a sheet-like layered structure was prepared on the surface of the stainless steel substrate by in-situ growth under hydrothermal conditions. Weigh 12mmol Bi(NO 3 ) 3 ·5H 2 O and 0.05g PVP were added to 70mL ethylene glycol, ultrasonically dispersed for 30min, 12mmol KI was weighed and dissolved in 10mL water, then the two solutions were mixed uniformly and transferred to a 100mL reactor. The pre-pretreated stainless steel mesh is immersed in the above mixed solution. Then the reaction kettle was heated to 120°C, and the reaction time was 12h. After the completion of the reaction, the stainless steel mesh was taken out, washed with absolute ethanol and distilled water in turn, and finally placed in a drying oven at 60°C for 6 hours. Weigh 0.16mmol of tetrabutylammonium bromide and add it to 80mL of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com