Preparation method of seasoned green shrimp

A technology of shrimp and green shrimp, applied in the functions of food ingredients, food freezing, food ingredients as taste improvers, etc., can solve the problems of surface crushing, desizing, affecting the taste and appearance of finished products, etc. Enhanced and convenient factory production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

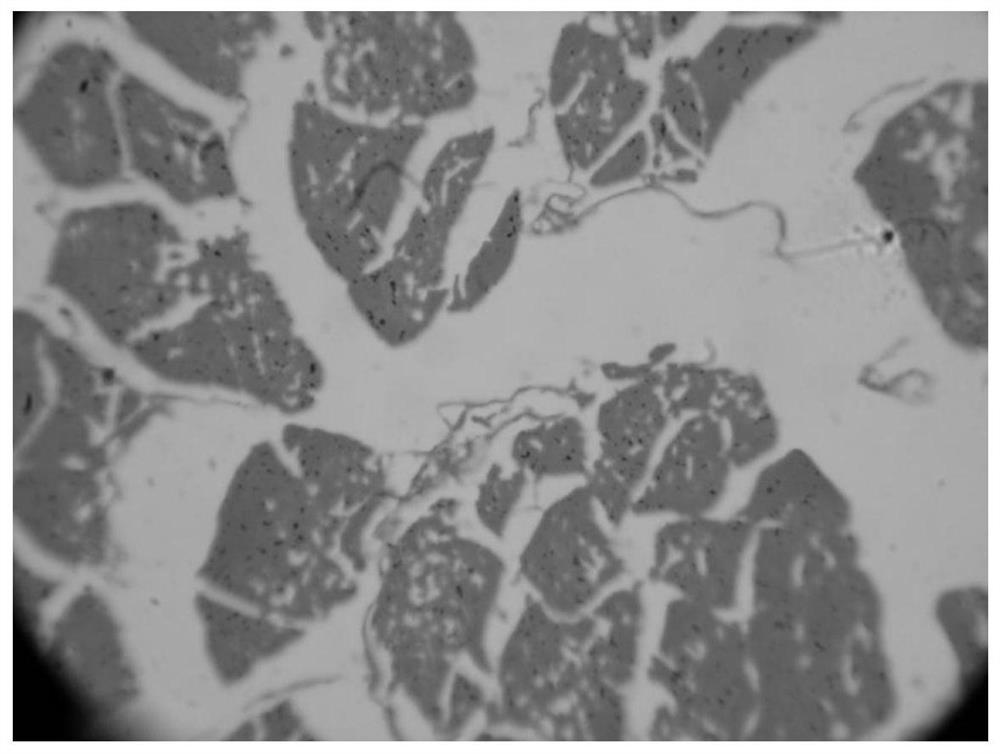

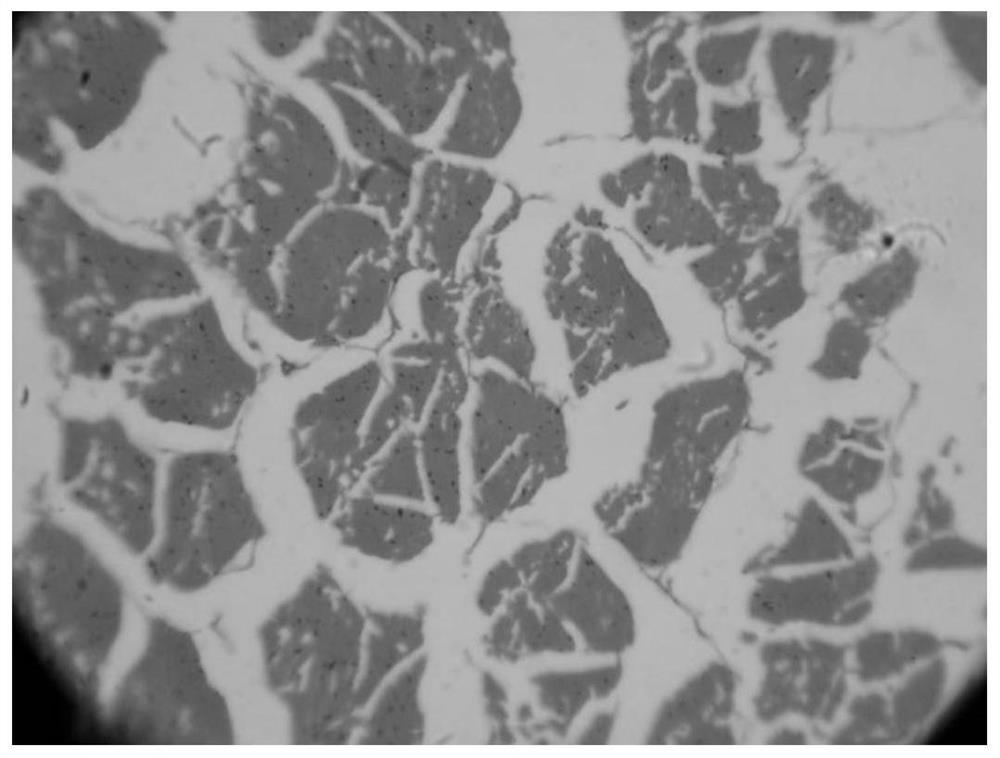

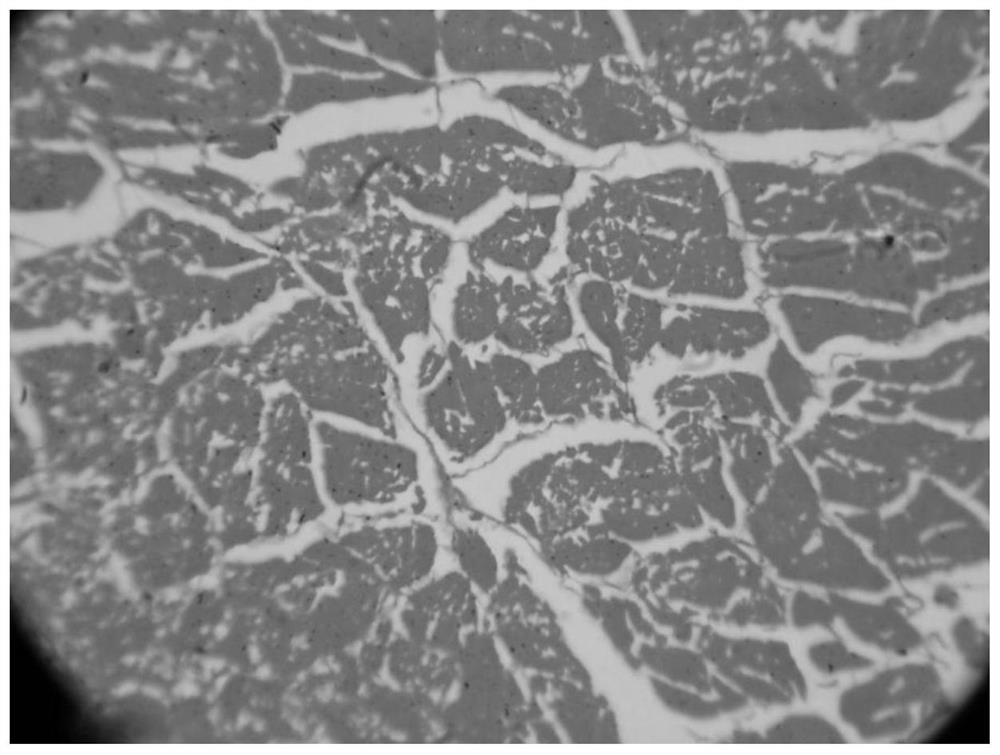

[0025] Such as figure 1 , 2 As shown, the present invention provides a preparation method of seasoned green shrimp, which comprises the following steps: before the pickling treatment, the fresh shrimp is repeatedly subjected to freezing and microwave thawing treatment, and the number of repetitions is twice; after the pickling treatment, the fresh shrimp is Carry out dehydration treatment to remove 10-15% of moisture. The present invention uses repeated freezing and microwave thawing treatments before pickling to partially destroy the muscle tissue of the shrimp, and the low-temperature freezing causes the ice crystals produced in the shrimp to cause mechanical damage to the muscle cells and tissues. At the same time, the heat from the inside out further promotes the fluffy muscle tissue. When the first microwave thawing is also the second freezing, more space can be formed in the shrimp muscle tissue to facilitate the formation of ice crystals. Shrimp muscle tissue will be...

Embodiment 1

[0035] The preparation method of the seasoned green shrimp of the present invention comprises the following steps:

[0036] 1) Put the fresh and live green shrimp into ice water to die suddenly, remove the head and shell, take the meat, and wash.

[0037] 2) After freezing the green shrimp at -40°C for 48 hours, put it into a tunnel-type microwave device for thawing. Tunnel microwave setting parameter power is 2-3KW, transmission speed is 0.2m / min, and processing capacity is 30kg / h. Repeat the above operation once.

[0038] 3) Add 0.8% sodium bicarbonate and 1% Nacl to marinate the shrimp after microwave thawing for 40 minutes, and rinse twice. Wherein the added amount of 0.8% baking soda is: 8mg / g; the added amount of 1% NaCl is: 10mg / g.

[0039] 4) Place the marinated shrimps in a dehydration device to remove 10% of the water.

[0040] 5) Place the dehydrated green shrimp in a vacuum tumbler, and put in the ingredients for tumbling. The tumbling time is 10min, and the tu...

Embodiment 2

[0044]The preparation method of the seasoned green shrimp of the present invention comprises the following steps:

[0045] 1) Put the fresh and live green shrimp into ice water to die suddenly, remove the head and shell, take the meat, and wash.

[0046] 2) Freeze fresh green shrimps at -40°C for 48-72 hours, then put them into tunnel microwave equipment for thawing. Tunnel microwave setting parameter power is 2-3KW, transmission speed is 0.2m / min, and processing capacity is 30kg / h.

[0047] 3) Add 0.8% sodium bicarbonate and 1% Nacl to marinate the shrimp after microwave thawing for 40 minutes, and rinse twice. Wherein the added amount of 0.8% baking soda is: 8mg / g; the added amount of 1% NaCl is: 10mg / g.

[0048] 4) The shrimp is placed in a dehydration device to remove 15% of the moisture.

[0049] 5) Place the dehydrated green shrimp in a vacuum tumbler, and put in the ingredients for tumbling. The tumbling time is 10min, and the tumbling speed is 20r / min. The ingredien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com