A kind of blasting charge method

A blasting charge and charging technology, which is applied in blasting and other directions, can solve problems such as nonel failure, difficulty in entering holes, and rising labor costs, and achieve the effects of avoiding the probability of failure, saving labor costs, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

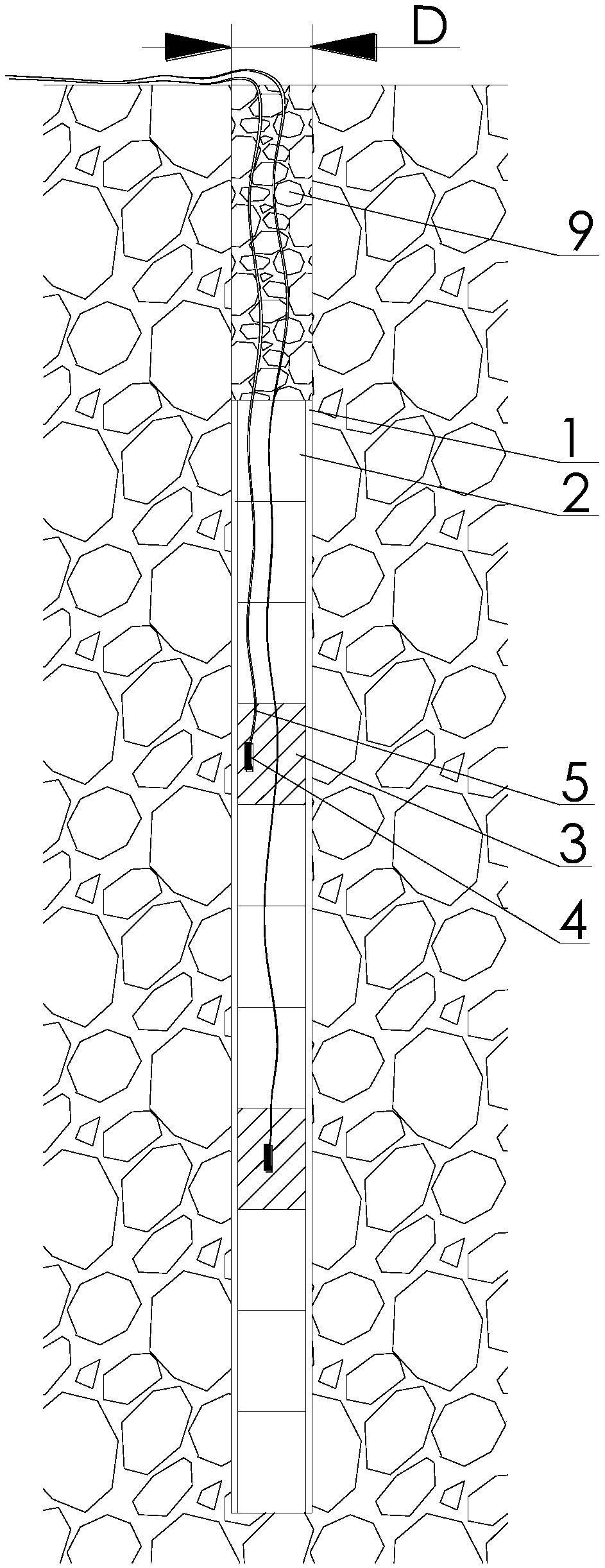

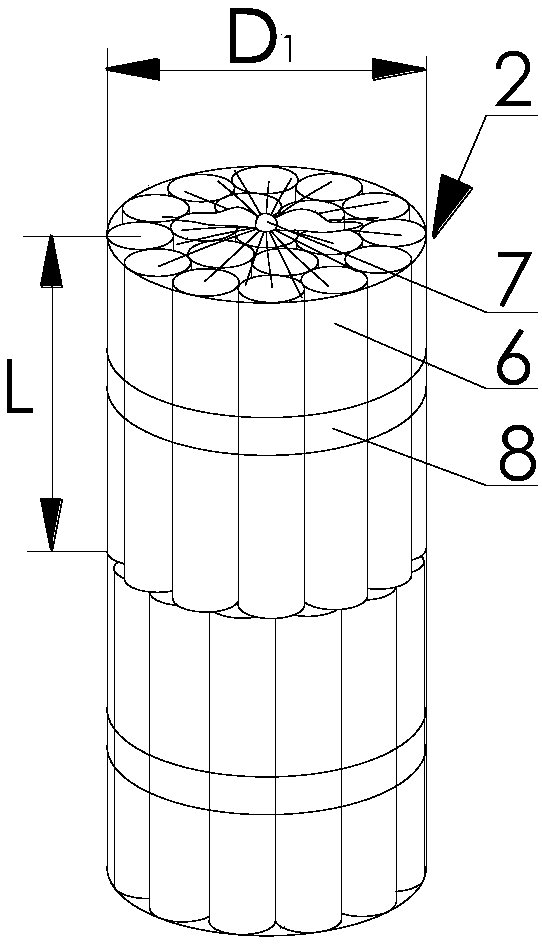

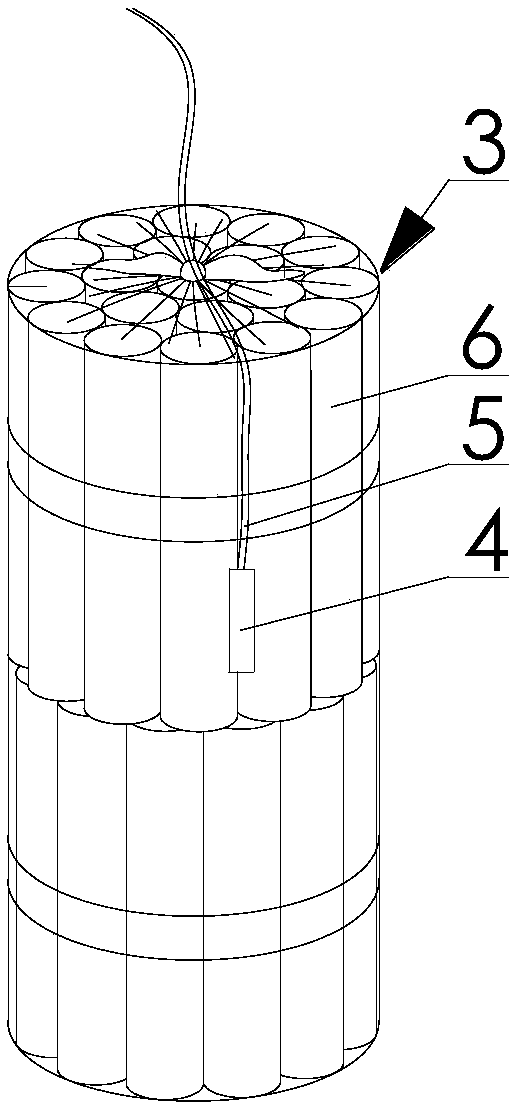

[0031] Such as figure 1 , figure 2 with image 3 The blasting charge structure shown includes a blasting charge column filled into the blast hole 1 and a sealing soil 9 for backfilling the blast hole 1. The blasting charge column is composed of staggered charge pack sections and detonating charge packs 3, The number of initiating charge packs 3 is at least two, and the charge pack sections are all composed of multiple charge packs 2 arranged along the length of the blast hole 1. The charge pack 2 includes a medicine bag 7 and a roll filled in the medicine bag 7 The explosive charge 6 and the detonating charge package 3 are composed of a charge package 2, a detonating tube detonator 4 arranged in the charge package 2, and a detonating tube 5 connected with the detonating tube detonator 4 and led out of the blast hole 1.

[0032] It should be noted that the blasting charge column is composed of staggeredly arranged charge pack sections and detonating charge packs 3, and the charge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com