Full-automatic steel bar bundling equipment

A fully automatic, reinforced technology, applied in the direction of bundling materials, parts of bundling machinery, paper/cardboard containers, etc., can solve problems such as low bundling efficiency, waste of steel wire, and substandard bundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

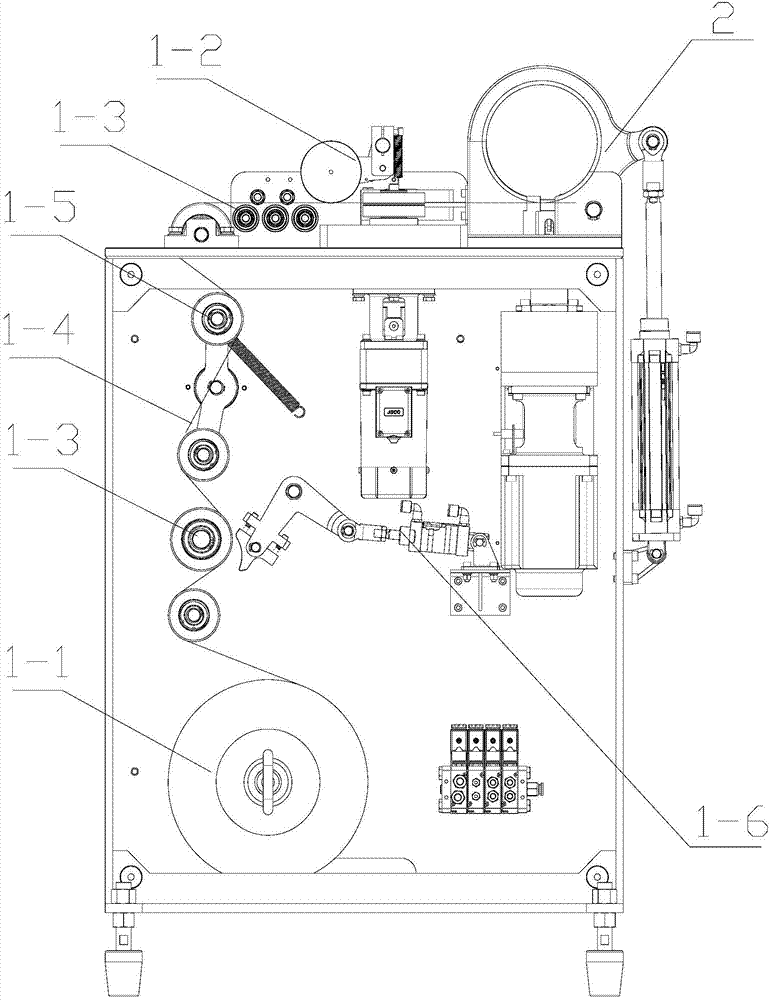

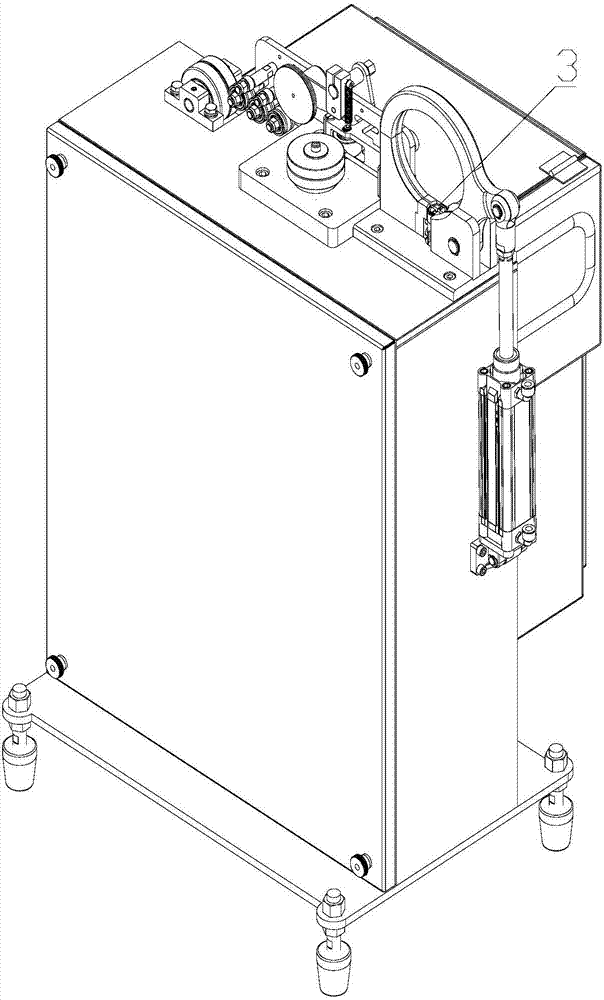

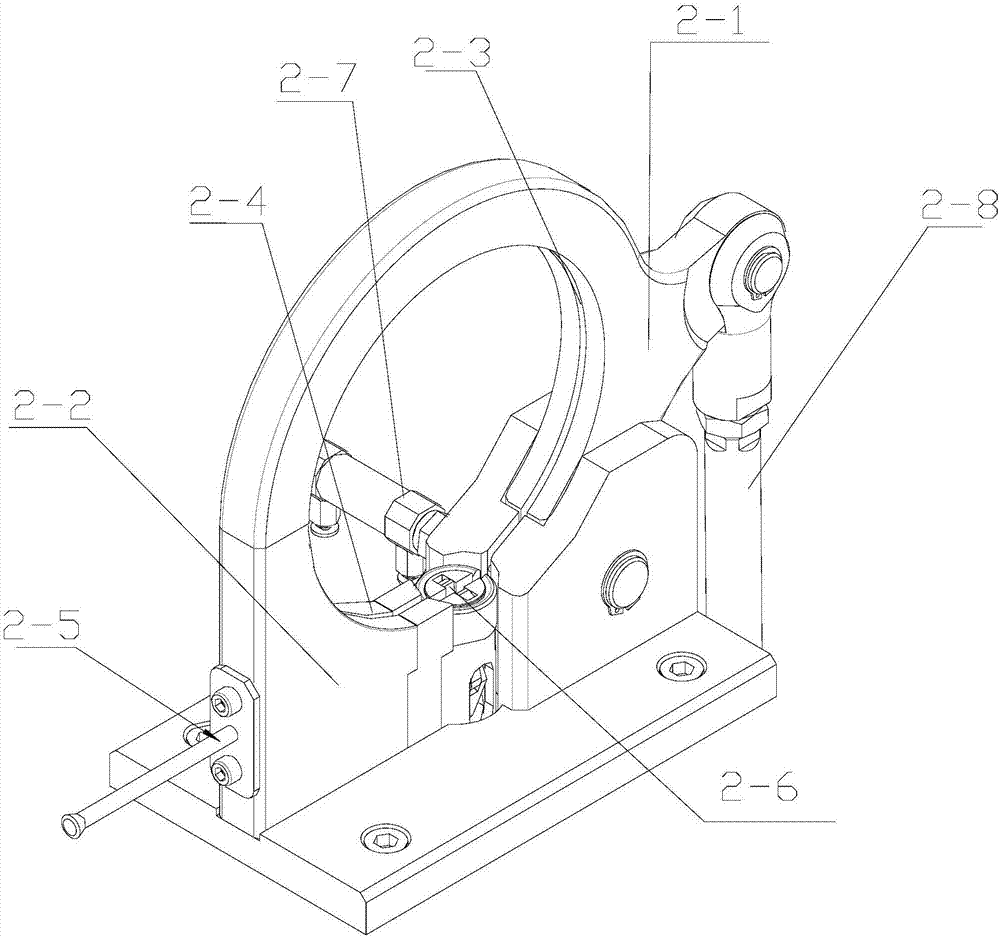

[0029] The present invention proposes a fully automatic steel bar binding equipment, which includes a frame, and the frame is provided with a wire feeding device 1, a guiding device 2 and a binding device 3;

[0030] The wire feeding device includes a wire feeding reel 1-1 and a fixed-length wire feeding and receiving mechanism 1-2, and several straightening rollers 1-3 are arranged between the wire feeding reel and the fixed-length wire feeding and receiving mechanism. The fixed-length wire feeding and collecting mechanism is used to transport / retract the bundled wires 1-4 on the wire feeding reel to the guide device for a preset length, and one side of the straightening roller is set to keep the bundled wires tensioned all the time s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com