A Method for Observing and Controlling the Interface of Inkjet Printing Film and Substrate

An inkjet printing and thin-film technology, which is applied in the direction of copying/marking methods, chemical instruments and methods, printing, etc., can solve the problems of long time consumption, high cost of sample preparation, high cost, etc., and achieve low equipment cost requirements, reliable observation results, The effect of simple sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below.

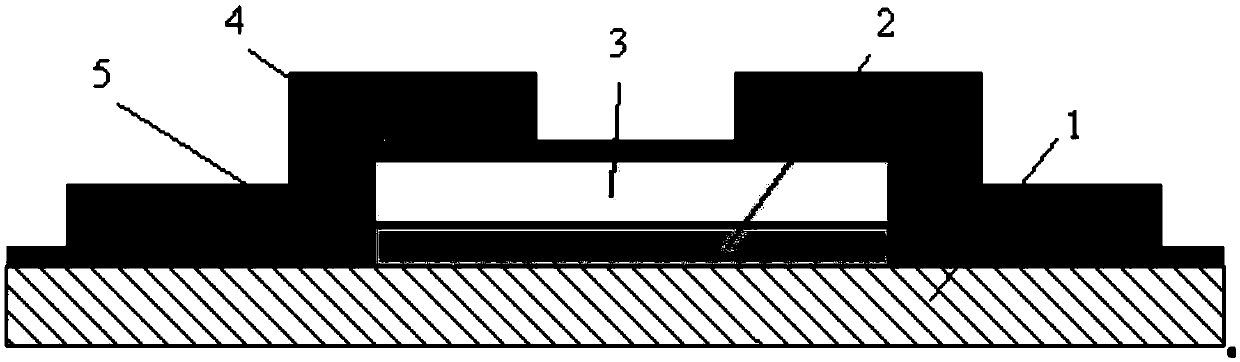

[0029] A method for observing and regulating the interface between an inkjet printing film and a substrate, comprising the following steps: first, printing an electrode pattern on a cleaned and dried substrate with a printer;

[0030] Secondly, the electrode inkjet printing film 5 undergoes the following solidification process: (1) first place the electrode inkjet printing film 5 in a liquid state at a temperature below 0°C for a period of time; The electrode inkjet printing film 5 is cured using high-power UV curing equipment, and the electrode inkjet printing film 5 moves during the curing process, exposing the interface area between the electrode inkjet printing film 5 and the substrate;

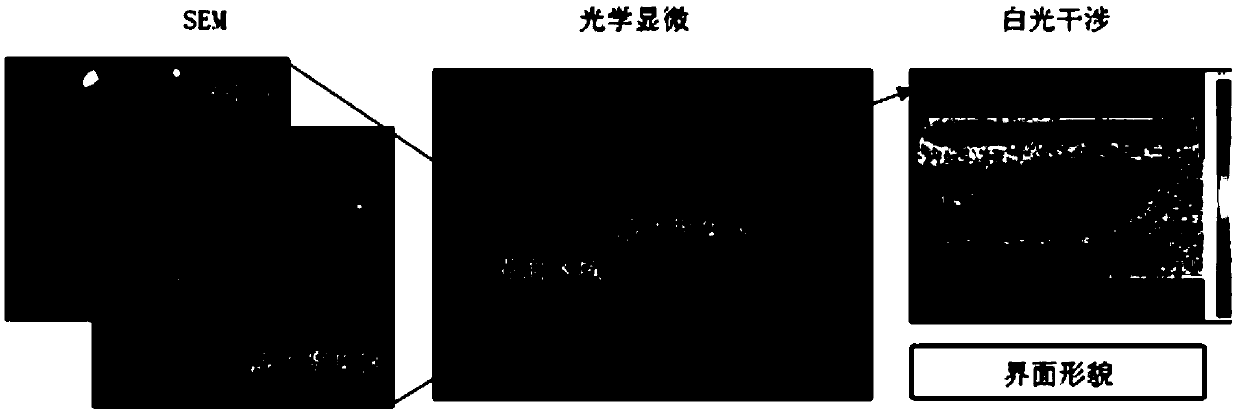

[0031] Finally, the interface morphology, composition and other information are directly observed and regulated by means of optical and electron microscopes.

[0032] The specific steps are:

[0033] Printer prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com