Cutting table

A cutting table and slitting technology, applied in sawing components, sawing equipment, circular saws, etc., can solve the problems of inability to adjust the height of use, no vacuuming device, no lifting table, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

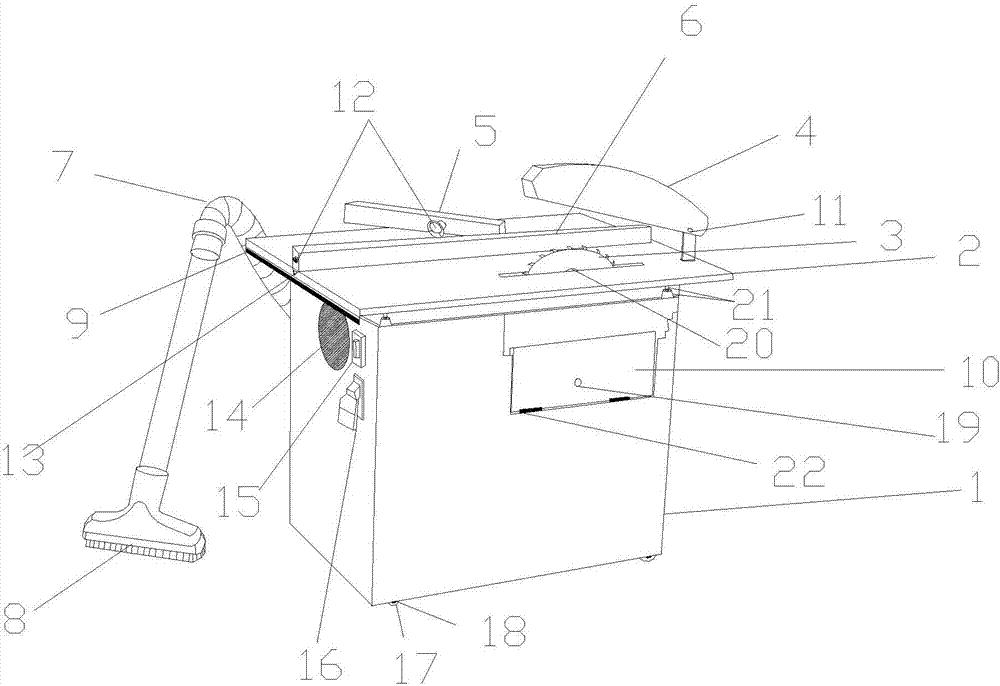

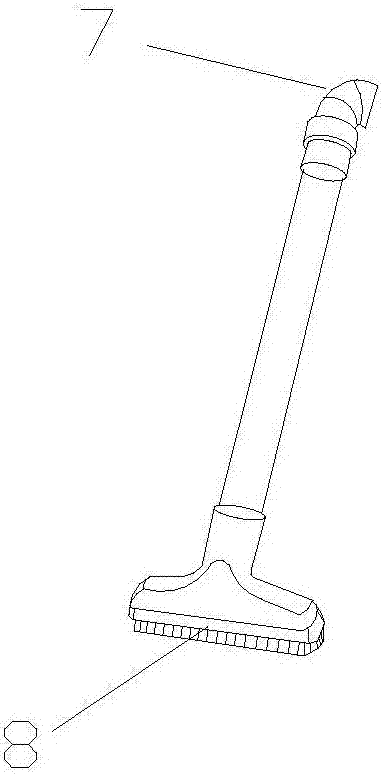

[0017] refer to figure 1 , figure 2 and image 3 A kind of cutting platform, its structure comprises base 1, lifting table 2, saw blade 3, protective cover 4, angle push ruler 5, slitting backer 6, vacuum telescoping pipe 7, vacuum brush 8 and measuring ruler 9, described The base 1 is connected with the lifting table 2 through the lifting support 21, the base 1 is provided with the saw blade 3 through the rotation shaft 20, the saw blade door 10 is arranged on the base 1 through the folding 22, and the saw blade warehouse The door 10 is provided with a door opening 19, the base 1 is provided with a roller 17 through a roller 18, the base 1 is provided with a saw blade power switch 15 cooling outlet 14, and the lifting platform 2 is respectively provided with a movable rotary 12. An angle pusher 5 and a slitting backer 6 are provided, the slitting backer 6 is provided with a pointer 13, the protective cover 4 is movably installed on the lifting platform 2 by screws 11, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com