Quickly replace the cylinder rod of the bending cylinder and the operation method of the gland seal

A gland sealing and operation method technology, applied in metal processing equipment, contour control, metal processing, etc., can solve the problems of potential safety hazards, affecting production rhythm, wasting hydraulic oil, etc., to reduce seal replacement time and improve maintenance efficiency and maintenance quality, and the effect of improving the operating rate of the rolling mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

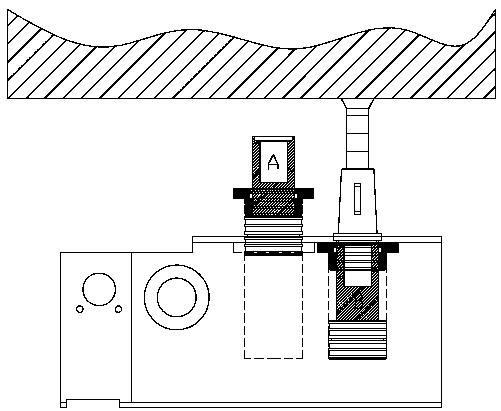

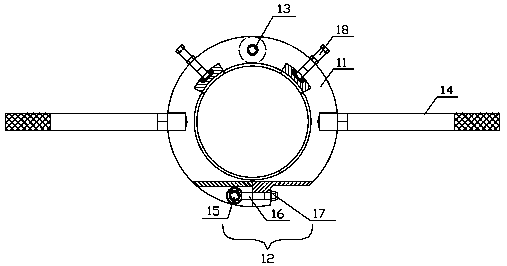

[0031] The operation method for quickly replacing the cylinder rod of the bending cylinder and the seal of the gland is characterized in that it includes the following steps:

[0032] Keep the hydraulic valve of the bending cylinder open, remove the bolts on the gland of the bending cylinder to be replaced, keep only the four diagonal bolts, and loosen the four bolts by at least one buckle;

[0033] Extend the cylinder rod A of the first roll bending cylinder that needs to be replaced through the hydraulic system, close the hydraulic valve of the roll bending cylinder and release the pressure, and then remove all the remaining four bolts on the gland;

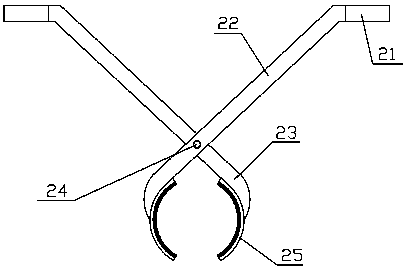

[0034] The second bending cylinder cylinder rod B on the same moving block as the first bending cylinder cylinder rod A is pressed back by the first jack, and the hydraulic oil inside the bending cylinder corresponding to the second bending cylinder cylinder rod B Jack up the cylinder rod A of the first roll bending cylinder th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com