a pot structure

A pot body and pot spout technology, applied in the field of pot body structure, can solve the problems of high tension of the metal shell, insufficient strength of the double-layer electric kettle shell and easy deformation, affecting the user experience, etc., and achieve the effect of easily covering the opening by the handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

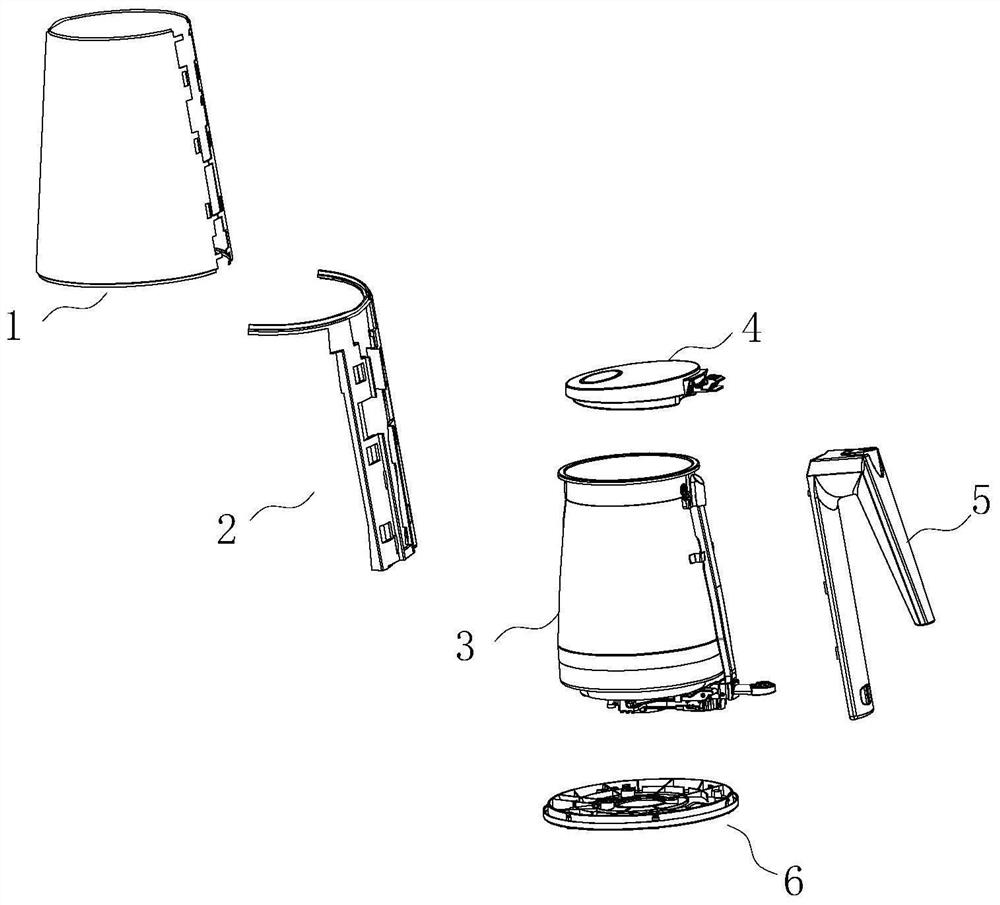

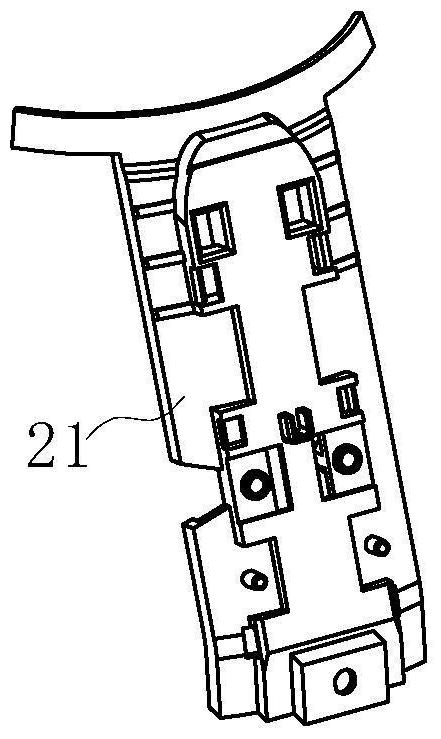

[0046] Such as Figure 1-Figure 2 As shown, a pot body structure, the pot body includes an inner tank 3, a metal shell 1, a handle 5, an opening is provided on one side of the metal shell 1, and the metal shell 1 is sleeved outside the inner tank 3 , the kettle body also includes a plastic bracket 2 arranged between the metal shell 1 and the inner tank 3, the plastic bracket 2 is used to support the metal shell 1, and the plastic bracket 2 includes a first bracket 21. The first bracket 21 is arranged at the opening and axially arranged along the outer wall of the inner container 3, and the handle 5 covers the opening. It should be noted that the first bracket 21 is axially arranged along the outer wall of the inner container 3 (the height direction of the inner container 3 is taken as the axial schematic illustration) should be understood in a broad sense, for example, including that the first bracket 21 is parallel to the axial direction, and at the same time It may also inc...

Embodiment 2

[0064] When there is a large gap between the metal shell 1 and the inner tank 3, if there is no supporting member to support the pot body during the user's use or transportation, the metal shell 1 is easily impacted by external force and causes indentation, which affects the appearance of the pot body sex.

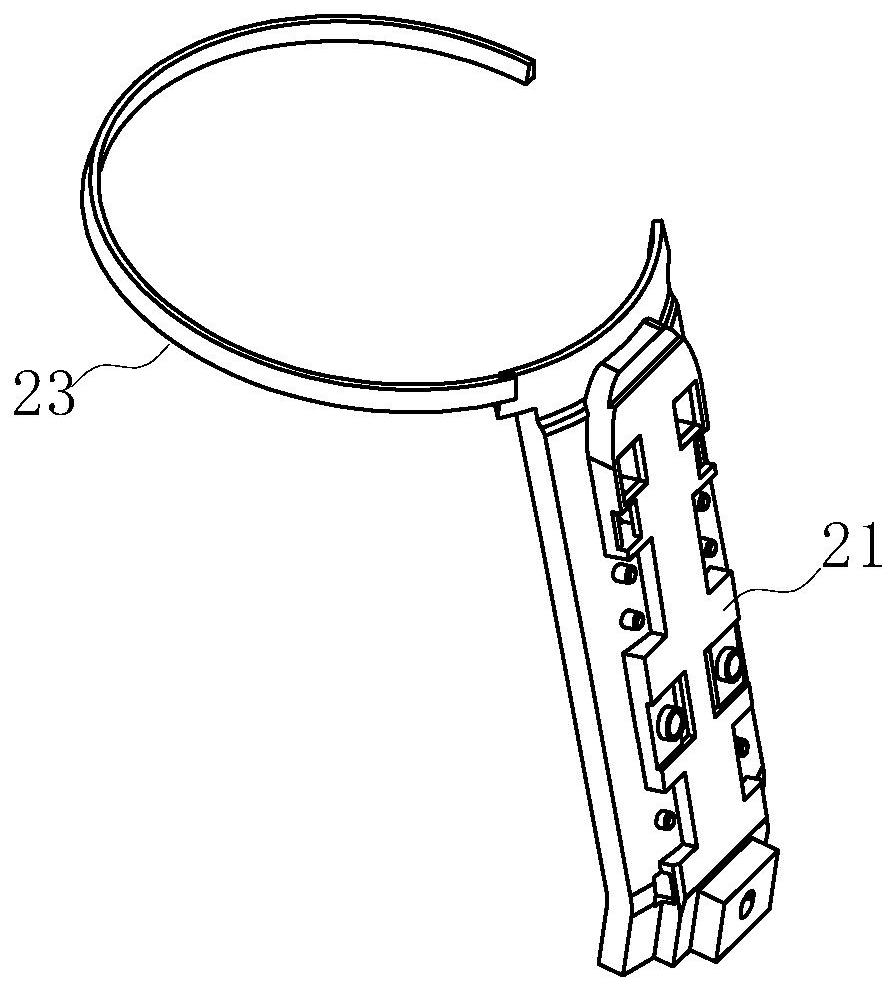

[0065] Based on the structure of embodiment 1, such as Figure 3-4 As shown, further, the plastic bracket 2 also includes a second bracket, which is a first extension bracket connected to one side of the first bracket 21 and extending circumferentially along the outer wall of the inner container 3 twenty three. It should be explained that the "circumferential direction" in "the second bracket is the first extension bracket 23 connected to the side of the first bracket 21 and extending along the outer wall of the inner container 3" (to surround the inner container 3 axis direction is a schematic illustration of the circumferential direction) should be understood in a broa...

Embodiment 3

[0080] Based on the structure described in embodiment 1 or 2, such as Figure 5 As shown further, when the size of the above-mentioned metal casing 1 is inconsistent up and down, the overall strength of the metal casing 1 is inconsistent, especially when the above-mentioned second installation port is large, the strength of the lower part of the metal casing 1 is weak, easy to deform, and cannot maintain its round shape. shape, in addition to increasing the ring bracket 24 described in embodiment 2 to strengthen the strength of the lower part of the metal shell 1, the base 6 can also be used to strengthen the strength. The base 6 can be shaped like a bowl, and its height is preferably 30 mm to 40 mm, so as to increase the overall rigidity of the base 6 , that is, the base 6 itself has enough rigidity to support the metal shell 1 .

[0081] Further, the above-mentioned bowl-shaped base 6 is provided with reinforcements, and a plurality of reinforcements are arranged at interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com