Unipolar-power rotary switch contact resistance motor

A rotary switch, unipolar technology, applied to synchronous motors for single-phase current, connected to control/drive circuits, shape/style/structure of winding conductors, etc., can solve low work efficiency, increased current, and waste of energy etc. to achieve the effects of low production cost, increased torque, and reduced electricity cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

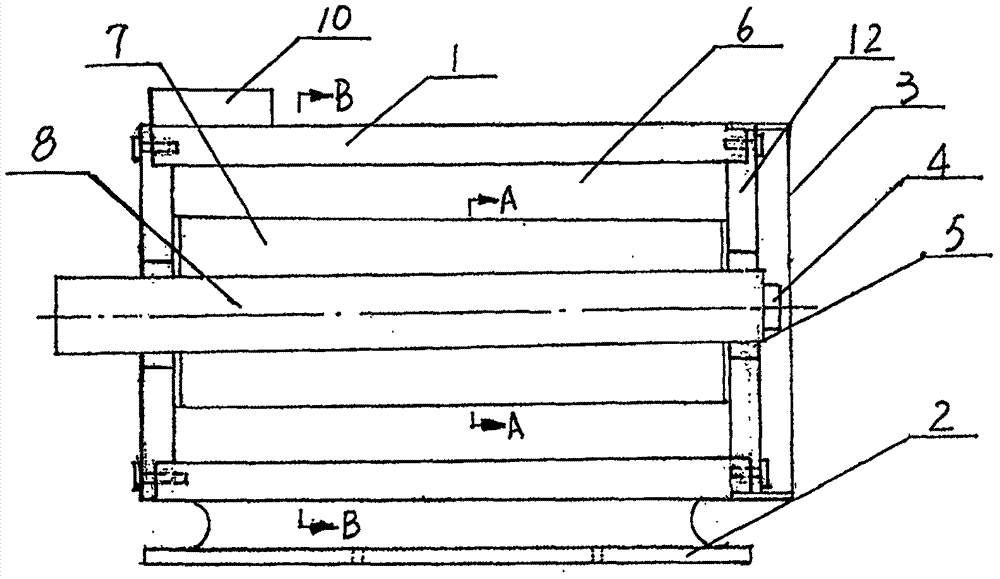

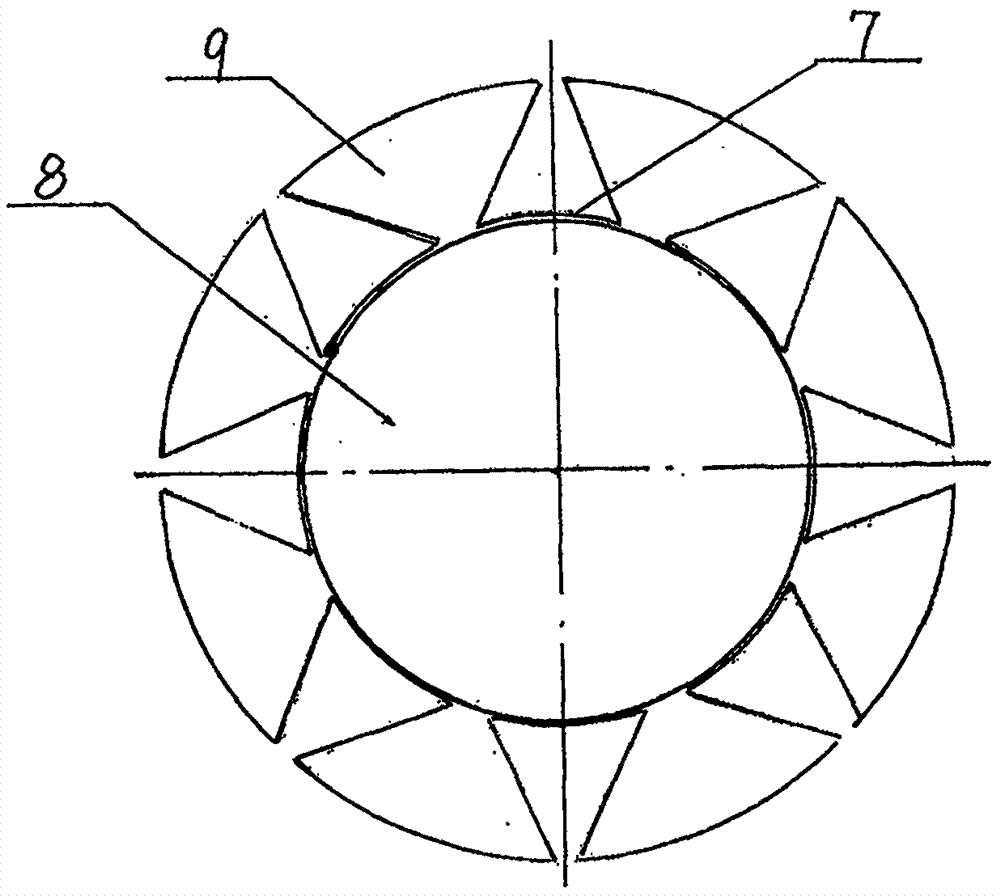

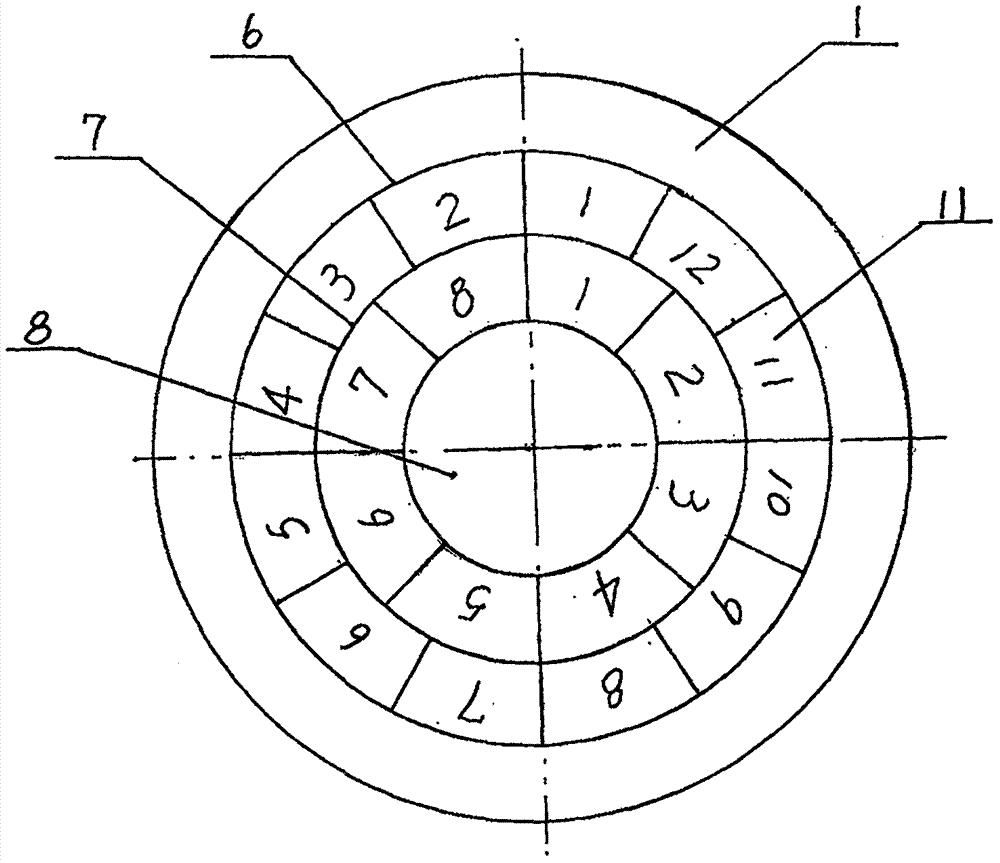

[0009] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, the end cover 12 of a unipolar power supply rotary switch bumper motor is arranged on both sides of the casing 1 with bolts, the copper sleeve 5 is fixedly arranged on the inner middle of both sides of the end cover 12, and the two ends of the rotating shaft 8 are movable on the copper In the sleeve 5, the stator 6 is fixed in the casing 1, the rotor 7 is fixedly arranged on the rotating shaft 8, and is movable in the middle of the stator 6, and the non-winding magnetic steel sheets 9 are sector-shaped, with 8 poles equidistantly arranged on the rotor 7 On the outer periphery, 12-pole rectangular winding coils 11 are arranged around the stator 6, the controller 10 is arranged on the upper left end of the casing 1, and is connected to the stator 6, and the sensor 4 is fixed on the right end of the rotating shaft 8, and communicated with the controller 10. The power supply of the stator 6 starts from the 1st pol...

Embodiment 2

[0010] Embodiment 2: as figure 1 , figure 2 , image 3 As shown, the 1, 4, 7, and 10 poles of the stator 6 winding coil 11 of the unipolar power supply rotary switch bumper motor are energized first, so that they pull the 1, 3, and 5 poles of the rotor 7 non-winding magnetic steel sheet 9 , 7 poles move to the 2, 5, 8, 11 pole directions of the stator 6 winding coil 11, when the 1, 3, 5, 7 poles of the rotor 7 non-winding magnetic steel sheet 9 move to the 1, 4 poles of the stator 6 winding coil 11 , 7, and 10 poles are directly below, the 1, 4, 7, and 10 poles of the stator 6 winding coil 11 are powered off, and at the same time the 2, 5, 8, and 11 poles of the stator 6 winding coil 11 are energized, pulling the rotor 7 non-winding magnetic steel The sheet 9 continues to move towards the 3, 6, 9, and 12 poles of the winding coil 11 of the stator 6. The 2, 5, 8, and 11 poles of the 6-winding coil 11 are powered off, and at the same time, the 3, 6, 9, and 12 poles of the st...

Embodiment 3

[0011] Embodiment 3: as figure 1 , figure 2 , image 3 As shown, a base 2 is provided at the lower part of the housing 1 of the unipolar power supply rotary switch bumper motor, and a shield 3 is provided at the right end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com