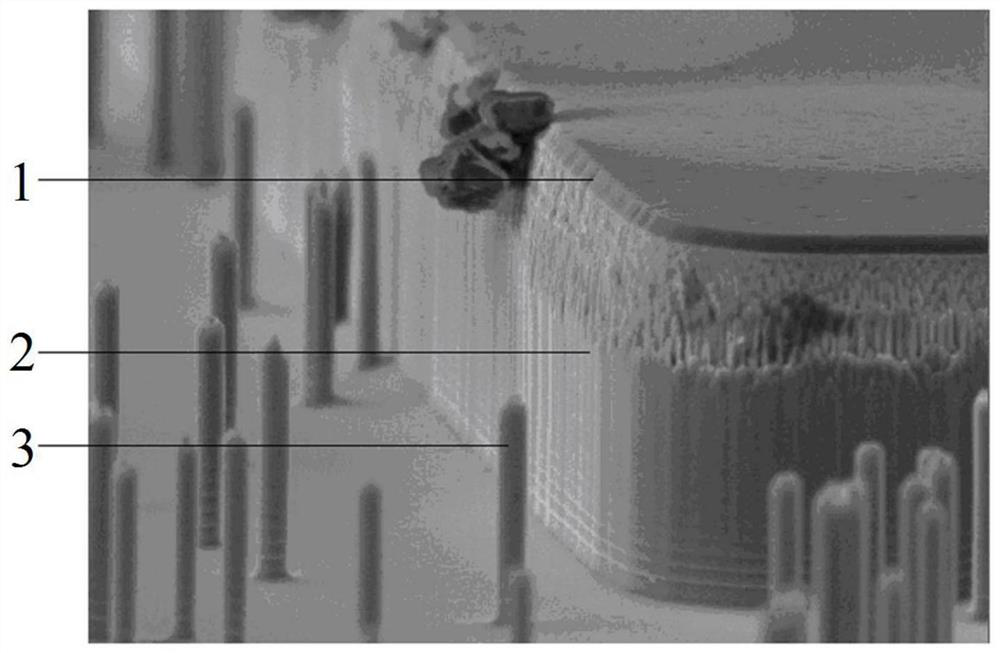

A method of etching inp material using rie equipment and etching inp material

An equipment and technology to be etched, applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problem of polymer by-product contamination of samples, etc., to achieve high machinable aspect ratio, controllable precision, and high graphics accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0037] Main equipment used among the present invention and term are explained as follows:

[0038] RIE, the full name is Reactive Ion Etching, reactive ion etching, is a dry etching process in the microelectronics industry.

[0039] When the Reactive Ion Etching (RIE, Reactive Ion Etching) equipment is working, it will generate an ion sheath with a thickness of hundreds of microns by applying a high-frequency voltage (RF, radio frequency) of 10 to 100 MHZ between the plate electrodes. A sample is placed in it, and ions hit the sample at high speed to complete chemical reaction etching.

[0040] Plasma Enhanced Chemical Vapor Deposition (PECVD, Plasma Enhanced Chemical VaporDeposition) equipment, which uses microwave or radio frequency to ionize the gas containing the constituent atoms of the film to form plasma locally, and the plasma chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com