Light diffusion plate and preparation method and purpose thereof

A light diffusion plate and light diffusion technology, applied in optics, optical components, instruments, etc., can solve the problems of high price, increased thickness, and significant cost of the light diffusion film, and achieve the improvement of haze and luminance, and increase the luminance , The effect of reducing the thickness of the module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] A method for preparing a light diffusion plate as described above, comprising the following steps:

[0074] 1) Preparation of light diffusing substrate;

[0075] 2) preparation of light diffusion coating;

[0076] 3) coating the light-diffusing coating on one or both sides of the light-diffusing substrate;

[0077] 4) Curing.

[0078] Preferably, the preparation of the light-diffusing substrate in step 1) includes adding light-diffusing particles into a molten transparent substrate material to make a light-diffusing plate.

[0079] Preferably, step 2) includes adding the light-diffusing particles into the binder resin and the diluent and mixing uniformly to prepare the light-diffusing coating.

[0080] Preferably, step 3) before coating the light-diffusing coating on one or both sides of the light-diffusing substrate, the surface of the light-diffusing substrate is treated with corona or plasma before coating. Surface corona or plasma treatment is performed to enhan...

Embodiment 1

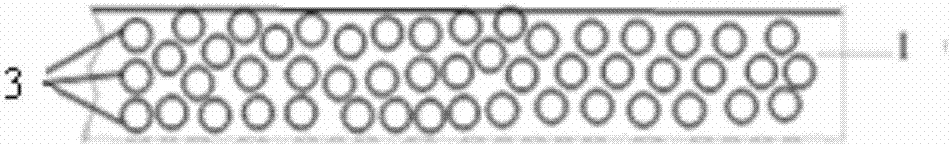

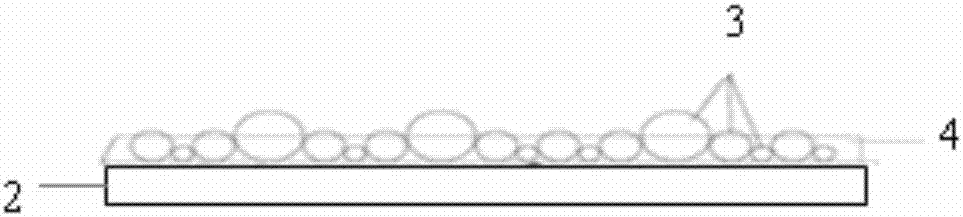

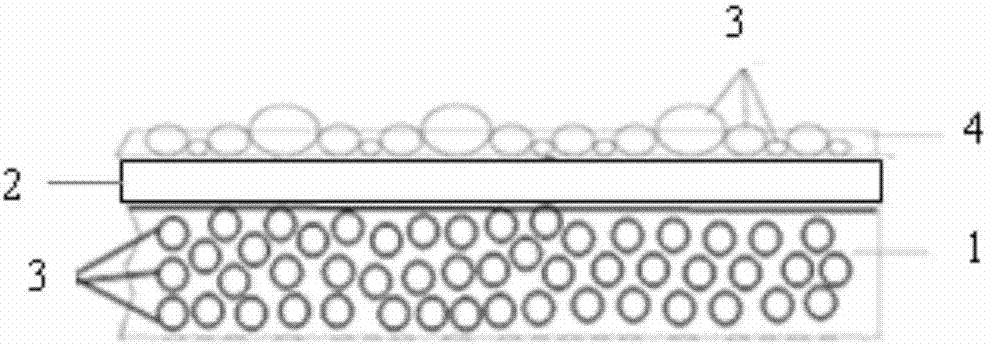

[0083] This embodiment discloses a light-diffusing substrate. The transparent substrate 100 in the light-diffusing substrate is a transparent PET substrate with a thickness of 1.50 mm. Organic light-diffusing particles are added to the molten PET material to make the light-diffusing substrate; A light-diffusing coating is provided on one or both surfaces of the diffusing substrate. The organic light-diffusing particles added inside the light-diffusing substrate are PMMA with an average particle diameter of 2 μm.

[0084] The binder resin in the light-diffusing coating is polyurethane, and the light-diffusing particles in the coating include organic large light-diffusing particles, organic small light-diffusing particles and inorganic light-diffusing particles. The organic light-diffusing particles are PMMA, and the inorganic light-diffusing particles are titanium dioxide. Among them, the particle size of the organic large light-diffusing particles is 10-13 μm, the maximum par...

Embodiment 2

[0089] This embodiment discloses a light-diffusing substrate, the transparent substrate 100 in the light-diffusing substrate is a transparent PMMA substrate with a thickness of 1.50 mm, and organic light-diffusing particles polysiloxane are added to the molten PMMA material to make light-diffusing Substrate; a light-diffusing coating is provided on one or both surfaces of the light-diffusing substrate. The polysiloxane light-diffusing particles added in the light-diffusing substrate have an average particle diameter of 2 μm.

[0090] The binder resin in the light diffusion coating is polyurethane, and the light diffusion particles in the light diffusion coating include organic large light diffusion particles, organic small light diffusion particles and inorganic light diffusion particles. The organic large light-diffusing particle is PMMA; the organic small light-diffusing particle is polysiloxane, and the inorganic light-diffusing particle is titanium dioxide. The average pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com