CFRP Porosity Characterization Method Based on Recursive Quantitative Analysis of Ultrasonic Backscattered Signals

A technology of ultrasonic backscattering and quantitative analysis, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves. It can solve the problems that the production process cannot establish a general porosity curve, high manufacturing difficulty, and bottom echo limitations. It achieves good promotion and Application prospects, low detection environment requirements, and the effect of overcoming strict requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

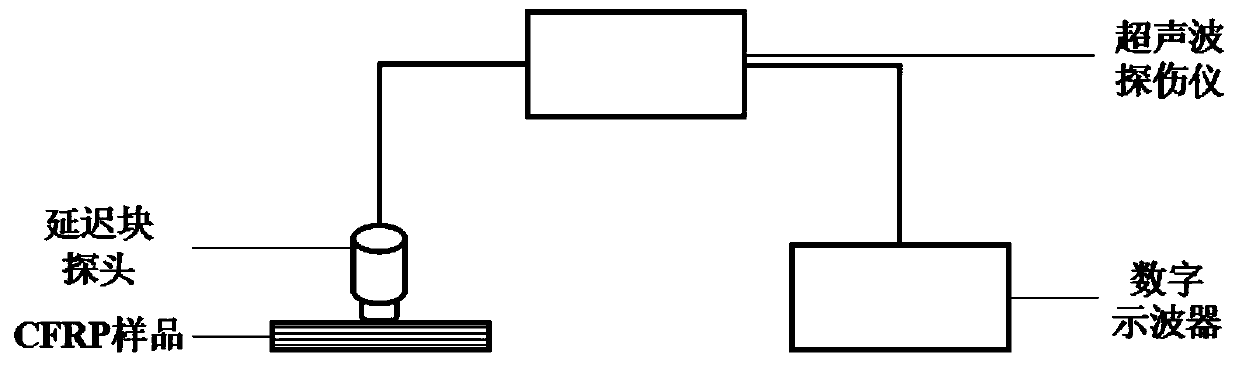

[0031] The connection diagram of the ultrasonic signal acquisition system used in the present invention is as follows figure 1 Shown. The experimental sample in this embodiment is a multi-directional CFRP laminate prepared by hot pressing of prepreg, with a fiber content of 69±3%. The specific calculation steps are as follows:

[0032] (1) Acquisition of ultrasonic backscatter signal

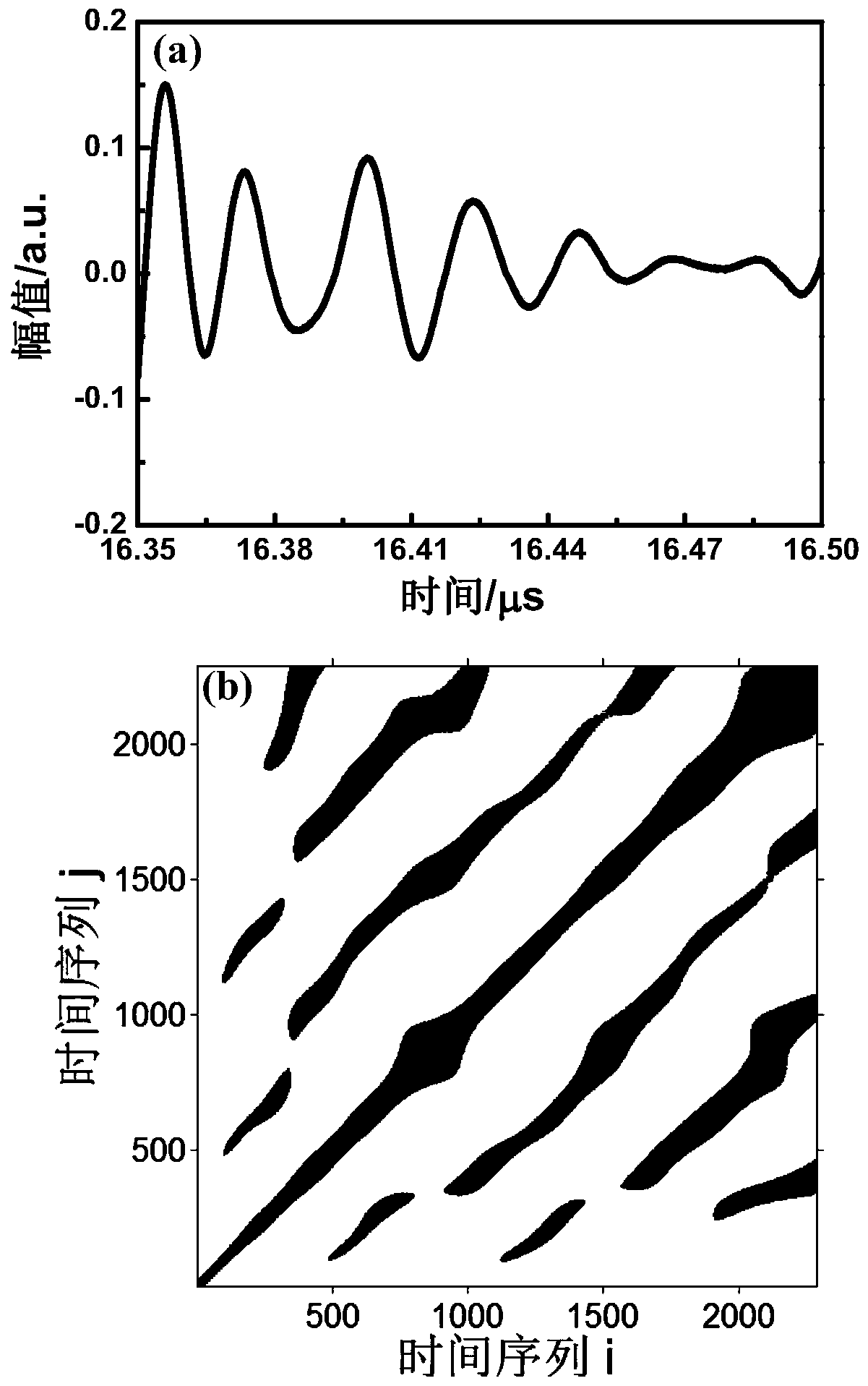

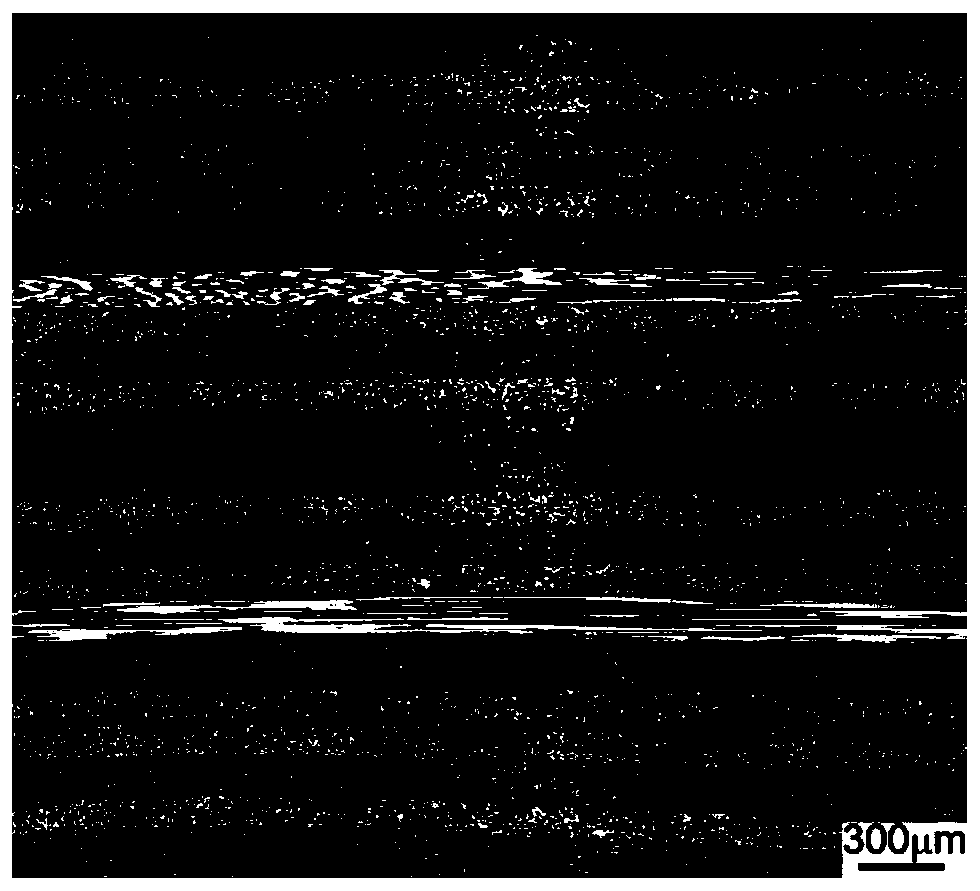

[0033] With the help of the ultrasonic C scanning system, the CFRP laminate is scanned by the ultrasonic reflection method, and the area with more uniform color is selected as the area to be studied according to the obtained scan image, using such as figure 1 The shown ultrasonic signal acquisition system performs ultrasonic backscatter signal acquisition on 32 locations in the study area, and uses the signal as the time series to be studied, such as figure 2 (a) Shown.

[0034] (2) Phase space reconstruction

[0035] For an ultrasonic backscatter signal containing 2500 points {x i }(i = 1, 2,..., 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com