A Blasting Construction Method of Equidistant Fan-shaped Holes in Tunnel Excavation and Expansion Area

A construction method and tunnel technology, which is applied in blasting and other directions, can solve problems such as unsatisfactory cutting effect, large clamping force of surrounding rock, and reduced cycle footage, and achieve the effect of promoting rational utilization, improving utilization rate, and uniform and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

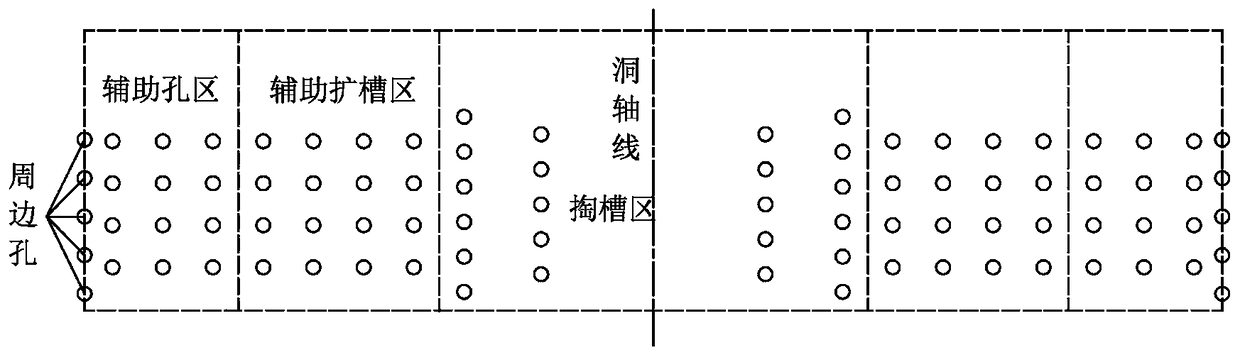

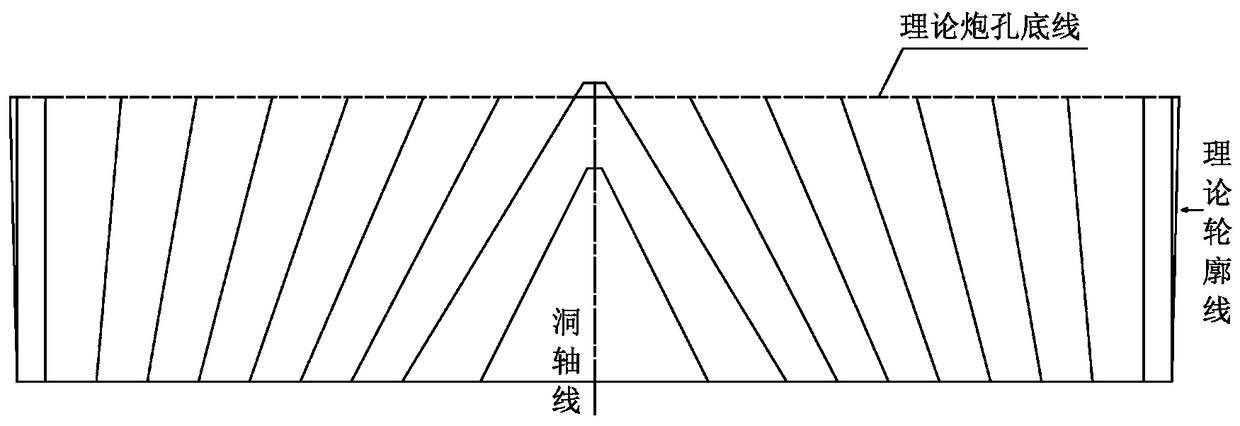

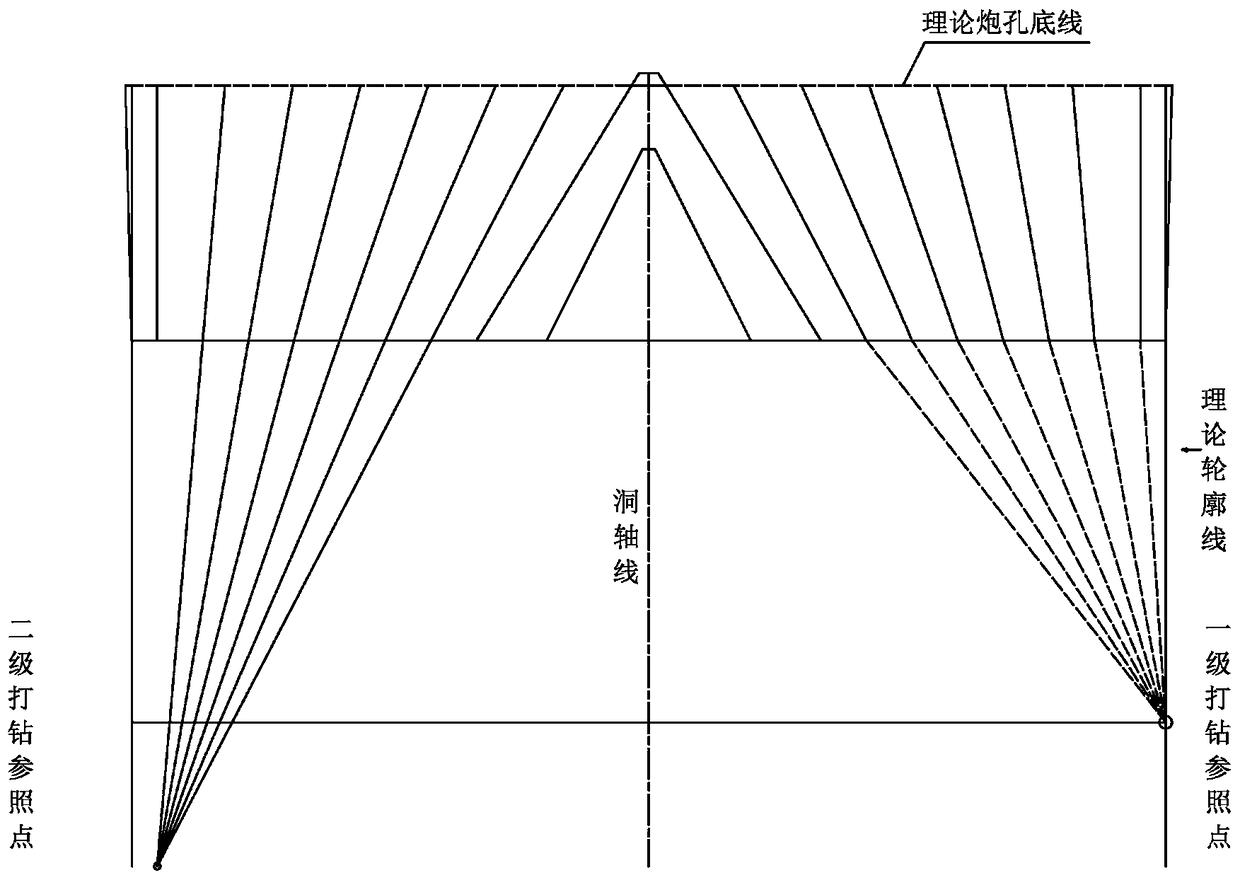

[0025] see Figure 1-3 , a blasting construction method for equidistant fan-shaped holes in a tunnel excavation and expansion area, comprising the following steps:

[0026] Step S1, design and drawing: tunnel blasting drilling forms are generally divided into peripheral holes, buffer holes (two-ring holes), auxiliary holes, expansion holes, cutting holes, etc., and various blast holes should be selected according to the actual situation during construction According to the blasting parameters of the tunnel, the blastholes should be arranged reasonably according to the lithology grade of the tunnel and the blasting design requirements of the tunnel. In order to meet the requirements of the drilling direction and the accuracy of the hole network parameters, the "equidistant fan-shaped hole layout method" is used for CAD software drawing, that is: according to the design hole network parameters and surrounding rock conditions, the tunnel face is excavated and expanded. The hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com