Pulsator washing machine and control method

A pulsator washing machine and pulsator technology, applied in the field of washing machines, can solve the problems of reducing the number of clothes, unreachable water flow, limited waterway height, etc., and achieve the effect of increasing the storage volume, enhancing the washing effect, and strong spraying force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

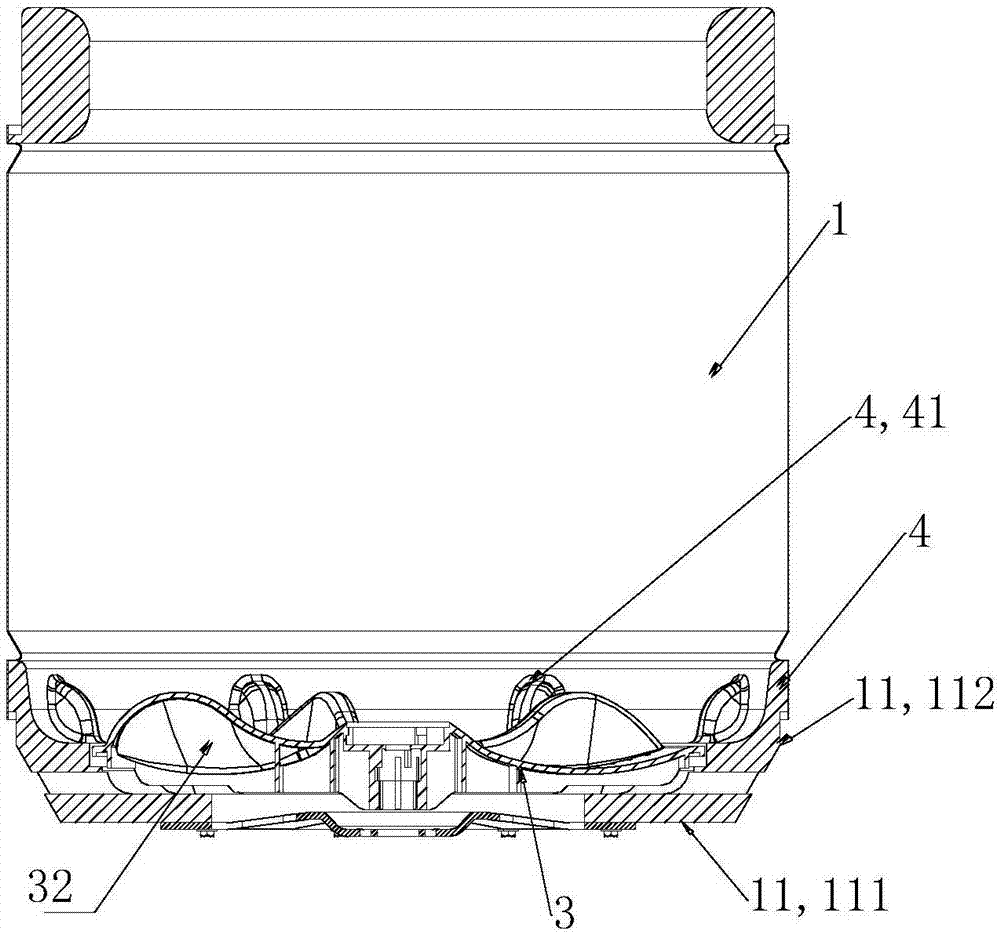

[0039] Such as Figure 1-5 As shown, the present embodiment provides a pulsator 3 washing machine, which includes an inner tub 1 and an outer tub 2, the inner tub 1 includes an inner tub bottom 11, and a pulsator 3 is arranged in the inner tub bottom 11, and the inner tub bottom 11 on the periphery of the pulsator 3 is provided with When the diversion channel 4 and the pulsator 3 rotate, the water flow is pushed along the diversion channel 4 to enter between the inner barrel 1 and the outer barrel 2 , climb up along the outer barrel 2 , and spray into the inner barrel 1 .

[0040] The inner wall of the inner barrel 1 of the pulsator 3 washing machine of the present embodiment is no longer provided with a water channel for spraying, but a diversion channel 4 is set on the bottom 11 of the inner barrel, and an outer barrel cover 5 is installed on the top of the outer barrel 2 . When the pulsator 3 rotates at a relatively high speed, it can push the water flow through the guide c...

Embodiment 2

[0049] Such as Figure 1-5 As shown, this embodiment is a further limitation of Embodiment 1. The inner barrel bottom 11 of this embodiment includes a bottom wall 111 and a side wall 112 connected to each other. The side wall 112 is arranged on the outer peripheral edge of the bottom wall 111. The bottom wall 111 and the The side walls 112 together form the inner barrel bottom 11 . The flow guiding channel 4 is set on the side wall 112 of the inner barrel bottom 11 , or at the junction of the side wall 112 and the bottom wall 111 .

[0050] The bottom wall 111 of the inner bucket bottom 11 is arranged horizontally, and the side wall 112 can be formed by bending the outer edge of the bottom wall 111 upward. On the side wall 112 and at the junction of the side wall 112 and the bottom wall 111, a laterally penetrating diversion channel 4 can be provided, which can divert the rotating water flow between the inner tub 1 and the outer tub 2, but the height of the diversion channel ...

Embodiment 3

[0066] This embodiment provides a control method of the pulsator washing machine in Embodiment 1 or Embodiment 2. Specifically, during washing, the washing machine controls the rotation of the pulsator 3 to push the water flow along the diversion channel 4 to enter between the inner tub 1 and the outer tub 2 , and climb up to the outer barrel cover along the outer barrel, and spray into the inner barrel. This process is a vortex washing process, and the pulsator runs at a higher speed, which is higher than the pulsator speed of the ordinary washing process, which can push the water to climb up to the outer bucket cover and spray into the inner bucket mouth.

[0067] When washing, the washing machine performs at least one vortex washing process. During this process, the inner and outer tubs of the washing machine are fixed, the pulsator runs at a high speed, and the water flow is pushed out by the convex ribs on the pulsator to the outer peripheral side, and passes through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com