A kind of high-gloss anti-friction varnish and its preparation method

A technology of varnish and tung oil, applied in the direction of coating, wax coating, etc., can solve the problems of poor surface adhesion of printed matter, hinder the development of water-based varnish, poor wear resistance, etc., achieve enhanced friction resistance and gloss, reduce Cleaning and maintenance costs, the smooth effect of ink conjunctiva

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

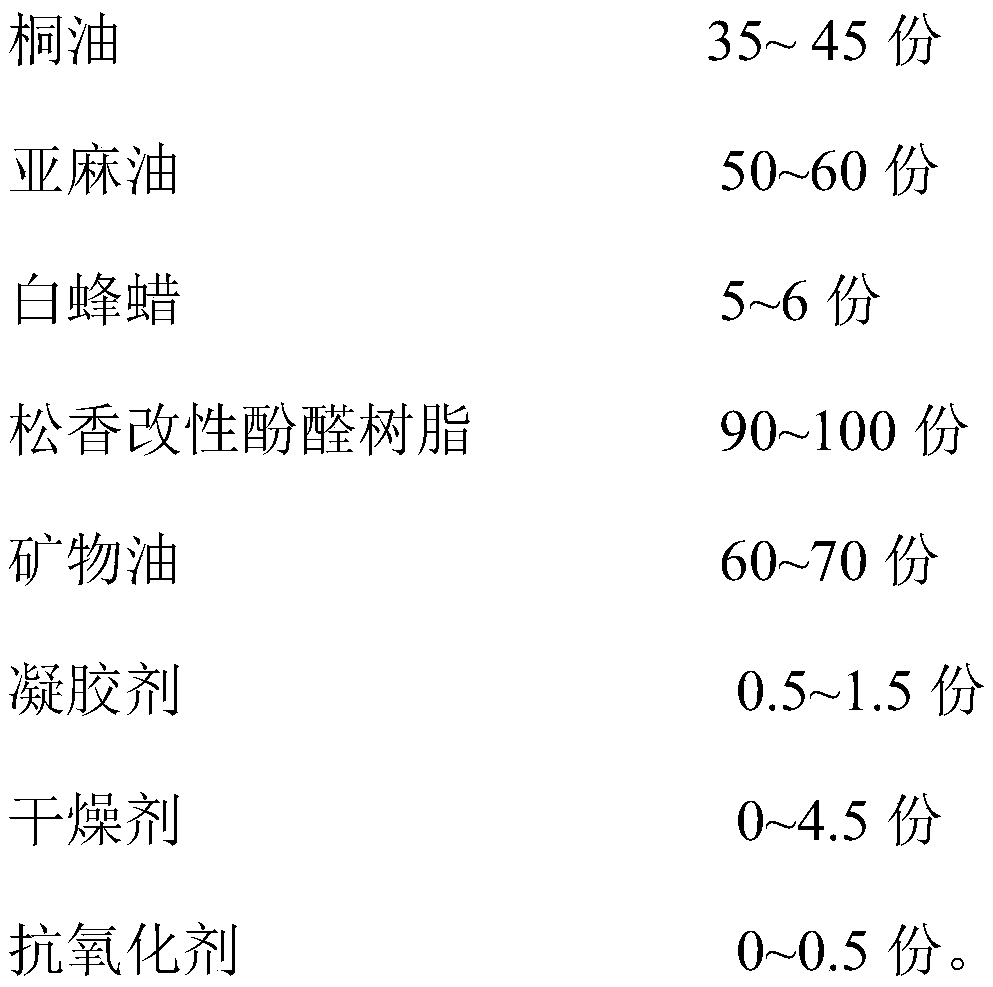

[0032] A kind of glazing oil, it is made up of the raw material of following weight part:

[0033]

[0034] Among them: rosin modified phenolic resin is 8376# resin and 8102# resin, the weights of both are: 400g, 550g respectively; mineral oil is 280# white oil; antioxidant is 2,6-di-tert-butyl-4-methyl base phenol; desiccants are cobalt dry liquid and manganese dry liquid, the weights of which are respectively: 13.5g and 27g.

[0035] Above-mentioned glazing oil is prepared by following steps:

[0036] S1. Mix 405g tung oil and 135g linseed oil, heat up to 90-110°C, add 54g beeswax, and stir to obtain a wax paste;

[0037] S2, heat up the wax paste in step S1 to 160-170°C, keep it warm, add 400g8376# resin and 550g8102# resin in 5 times under constant stirring; then heat up to 230-240°C, add 432g linseed oil, 500g mineral oil; Then lower the temperature to 155-165°C, add 10.8g of liquid aluminum and 27g of mineral oil;

[0038] S3. The temperature of the mixture obtaine...

Embodiment 2

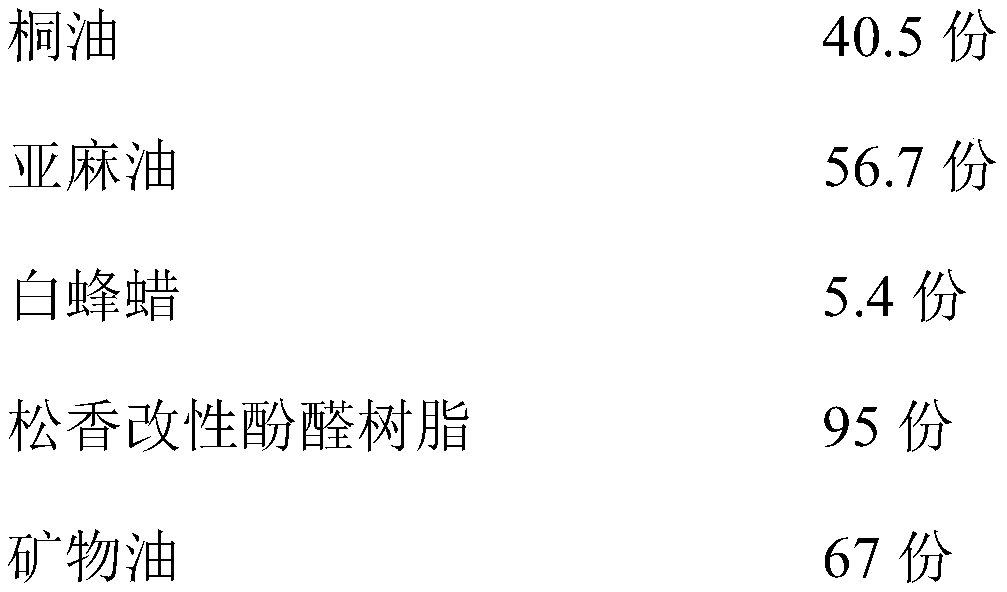

[0042] A kind of glazing oil, it is made up of the raw material of following weight part:

[0043]

[0044] Among them: rosin modified phenolic resin is 8376# resin and 8102# resin, the weights of both are: 380g and 570g respectively; mineral oil is 280# white oil; antioxidant is 2,6-di-tert-butyl-4-methyl base phenol; desiccant is cobalt dry liquid and manganese dry liquid, the weight of both is: 12.0g, 28.5g.

[0045] Above-mentioned glazing oil is prepared by following steps:

[0046] S1. Mix 392.2g tung oil and 109g linseed oil, heat up to 90-110°C, add 54g beeswax, and stir to obtain a wax paste;

[0047] S2, heat up the wax paste in step S1 to 160-170°C, keep warm, add 380g8376# resin and 570g 8102# resin in 5 times under constant stirring; then heat up to 230-240°C, add 436g linseed oil, 513g mineral oil ;Then lower the temperature to 155~165℃, add 10.8g liquid aluminum and 27g mineral oil;

[0048] S3. The temperature of the mixture obtained in step S2 is raised ...

Embodiment 3

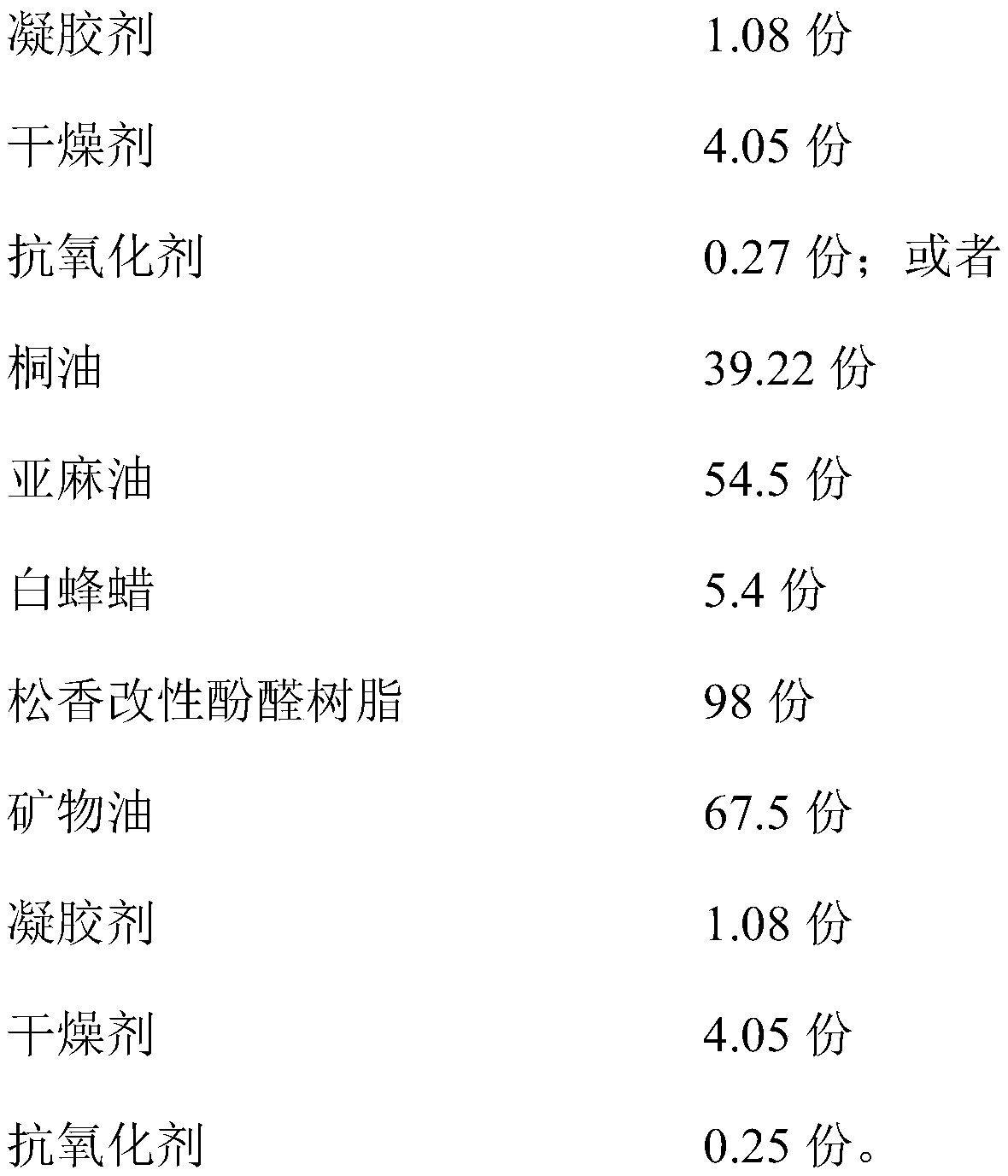

[0052] A kind of glazing oil, it is made up of the raw material of following weight part:

[0053]

[0054]

[0055] Among them: rosin modified phenolic resin is 8376# resin and 8102# resin, the weights of both are: 500g and 500g respectively; mineral oil is 280# white oil; antioxidant is 2,6-di-tert-butyl-4-methyl base phenol; desiccants are cobalt dry liquid and manganese dry liquid, the weights of which are respectively: 15g and 30g.

[0056] Above-mentioned glazing oil is prepared by following steps:

[0057] S1. Mix 450g tung oil and 143g linseed oil, heat up to 90-110°C, add 50g beeswax, and stir to obtain a wax paste;

[0058] S2, heat up the wax paste in step S1 to 160-170°C, keep it warm, add 500g8376# resin and 500g8102# resin in 7 times under constant stirring; then heat up to 230-240°C, add 357g linseed oil, 522g mineral oil; Then lower the temperature to 155-165°C, add 15g of liquid aluminum and 27.45g of mineral oil;

[0059] S3. The temperature of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com