Treating gent for waterborne scorched leather and preparation method thereof

A leather treatment agent and water-based technology, which is applied in the field of water-based scorched leather treatment agent and its preparation, can solve the problems of difficult water-based scorched leather effects, etc., and achieve the effect of good wax luminosity, good transparency and strong burnt feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

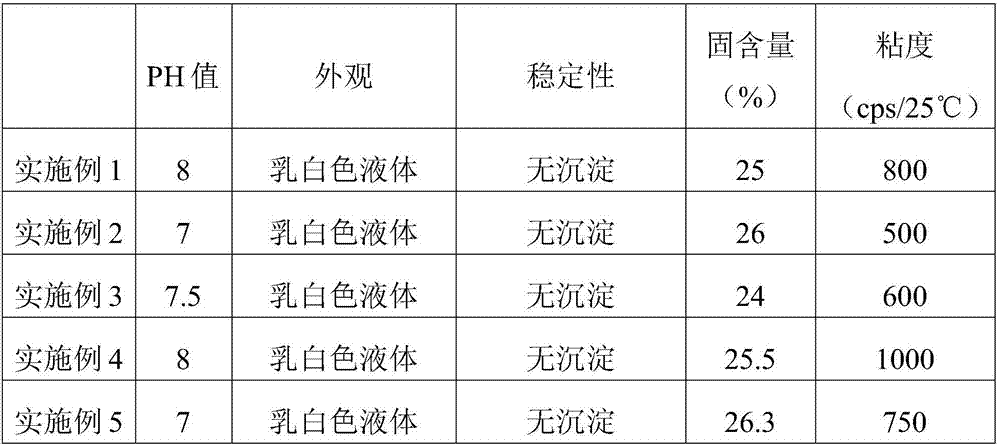

Examples

Embodiment 1

[0021] The water-based scorched leather treatment agent is composed of the following components: 30kg water-based polyurethane resin, 20kg water-based wax emulsion, 45kg deionized water, 2kg silicone handle agent, 6kg silica matting powder, 0.8kg dispersant, 0.2kg Defoamer, 1kg thickener.

[0022] The preparation method of the water-based scorching leather treatment agent of the embodiment of the present invention 1 comprises the following steps:

[0023] 1) Weigh each component material in proportion, mix 15kg water-based polyurethane resin, 45kg deionized water, 6kg silica matting powder, and 0.8kg dispersant;

[0024] 2) Fully stir the mixture at a stirring speed of 1500r / min, and disperse for 30min;

[0025] 3) Add the remaining 15kg water-based polyurethane resin to the mixture, and mix the 20kg water-based wax emulsion evenly;

[0026] 4) Fully stir the mixture at a stirring speed of 100r / min, and disperse for 15min;

[0027] 5) Add 0.2kg of defoamer, 2kg of organosil...

Embodiment 2

[0030] The water-based burnt leather treatment agent is composed of the following components: 40kg water-based polyurethane resin, 30kg water-based wax emulsion, 50kg deionized water, 1.5kg organic silicon handle agent, 5kg silica matting powder, 1kg dispersant, 0.3kg Defoamer, 0.8kg thickener.

[0031] The preparation method of the water-based scorching leather treatment agent of the embodiment of the present invention 2 comprises the following steps:

[0032] 1) Weigh each component material in proportion, mix 20kg water-based polyurethane resin, 50kg deionized water, 5kg silica matting powder, and 1kg dispersant evenly;

[0033] 2) Fully stir the mixture at a stirring speed of 1500r / min, and disperse for 45min;

[0034] 3) Add the remaining 20kg water-based polyurethane resin to the mixture, and mix the 30kg water-based wax emulsion evenly;

[0035] 4) Fully stir the mixture at a stirring speed of 100r / min, and disperse for 20min;

[0036] 5) Add 0.3kg of defoamer, 1.5kg...

Embodiment 3

[0039] The water-based burnt leather treatment agent is composed of the following components: 36kg water-based polyurethane resin, 25kg water-based wax emulsion, 30kg deionized water, 0.5kg silicone handle agent, 8kg silica matting powder, 0.6kg dispersant, 0.5kg kg defoamer, 0.6kg thickener.

[0040] The preparation method of the water-based scorching leather treatment agent of the embodiment of the present invention 3 comprises the following steps:

[0041] 1) Weigh each component material in proportion, mix 18kg water-based polyurethane resin, 30kg deionized water, 8kg silica matting powder, and 0.6kg dispersant;

[0042] 2) Fully stir the mixture at a stirring speed of 1500r / min, and disperse for 40min;

[0043] 3) Add the remaining 18kg water-based polyurethane resin to the mixture, and mix the 20kg water-based wax emulsion evenly;

[0044] 4) Fully stir the mixture at a stirring speed of 100r / min, and disperse for 10min;

[0045] 5) Add 0.5 kg of defoamer, 0.5 kg of o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com