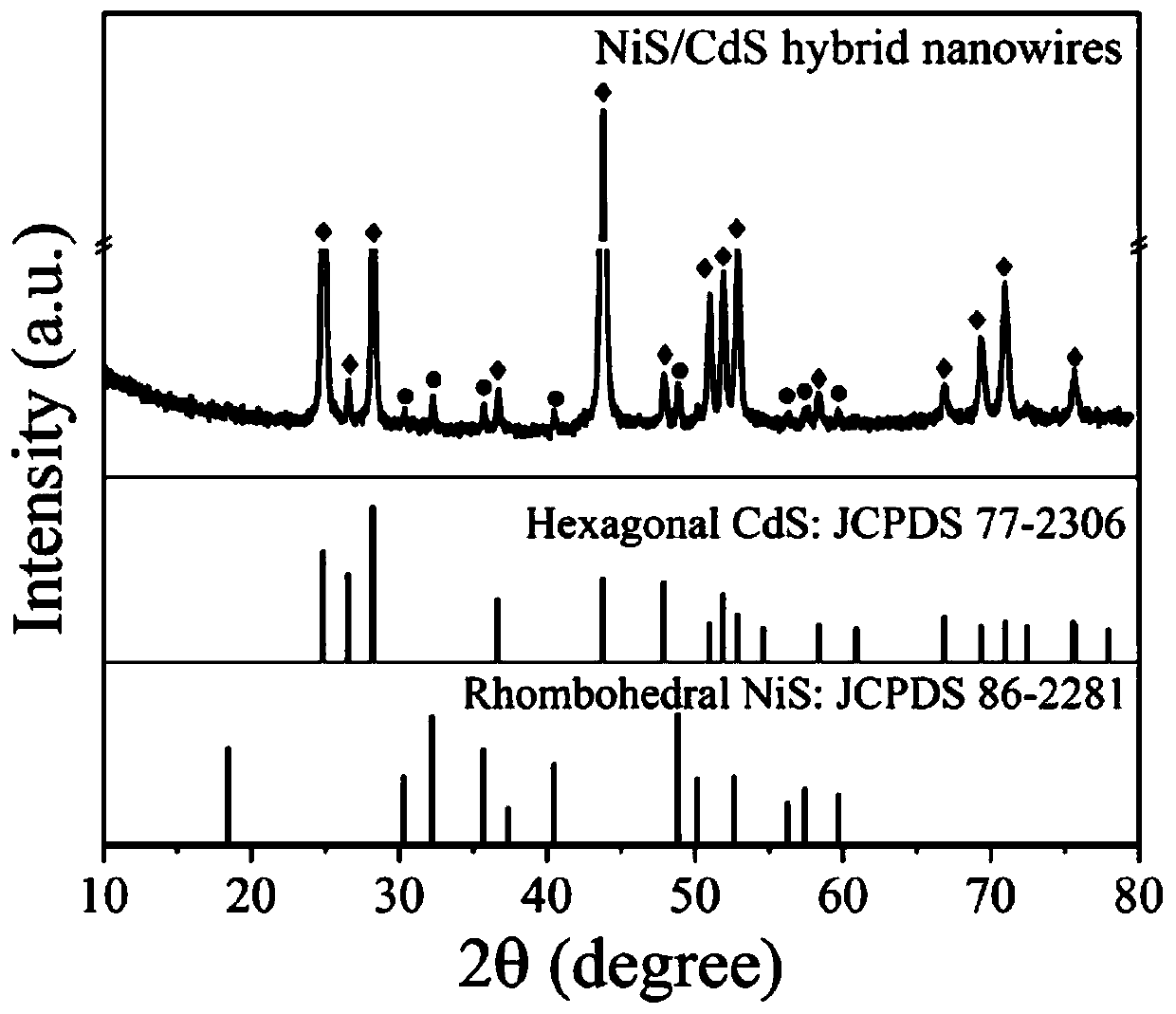

A nickel sulfide-cadmium sulfide nanowire heterostructure and its preparation method

A heterostructure, cadmium sulfide technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of poor electrical conductivity, limited degree of visible light catalysis, and poor light absorption, and achieve electrical conductivity. The effect of good performance, strictly controllable synthetic growth conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of nickel sulfide-cadmium sulfide nanowire heterostructure proposed by the present invention comprises the following steps and contents:

[0033] (1) In the autoclave, first add ethylenediamine, then add sulfur powder and cadmium acetate at a molar ratio (2-3): 1, stir well to make it evenly mixed. After sealing the reactor, heat it to 180-240°C at a speed of 5-20°C / min and react for 18-24 hours. After naturally cooling to room temperature, the reaction kettle was opened, and the generated precipitate was alternately centrifuged and washed with deionized water and alcohol for 3-5 times to obtain pure cadmium sulfide nanowires. Then, cadmium sulfide nanowires were dispersed in deionized water and set aside.

[0034] (2) In the beaker, first add deionized water, then add nickel acetate, then add the aqueous dispersion of cadmium sulfide nanowires, and keep stirring for 3-5 hours. Then, add thiourea and sodium hypophosphite in sequence. After stir...

Embodiment 1

[0040] Example 1: In a 50mL autoclave, add 40mL of ethylenediamine, then sequentially add 0.2665g of cadmium acetate and 0.0641g of sulfur powder, stir well to make it evenly mixed. After sealing the reaction vessel, it was heated to 200° C. at a speed of 15° C. / min and reacted for 20 hours. After naturally cooling to room temperature, the reaction kettle was opened, and the precipitate formed was washed with deionized water and alcohol alternately and centrifuged three times, and then the product was dispersed in 40 mL of deionized water for later use.

[0041] In a 100mL beaker, add 40mL of deionized water, then dissolve 40mg of nickel acetate into it, then add 10mL of the above-mentioned aqueous dispersion of cadmium sulfide nanowires (containing about 29 mg of cadmium sulfide), and continue stirring at room temperature for 3 hours. Add 50mg of thiourea and 60mg of sodium hypophosphite to the mixture, and continue to stir until it is evenly mixed. Finally, the mixture was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com