Deep hole drilling machine capable of automatically replacing gun drill and control method

A technology of automatic replacement and deep hole drilling machine, which is applied in the direction of drilling/drilling equipment, boring/drilling, manufacturing tools, etc. It can solve the problems of many precautions, poor gun drilling strength, and easy bending, so as to reduce production cost, reduce labor intensity, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

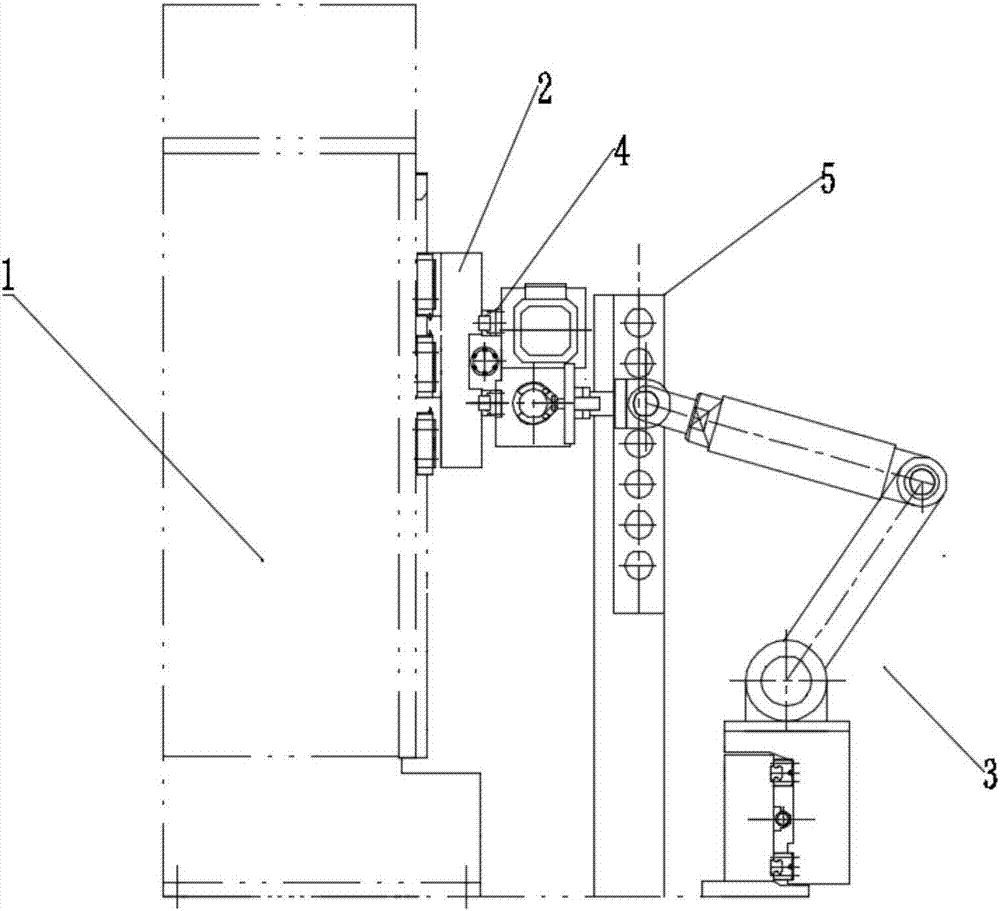

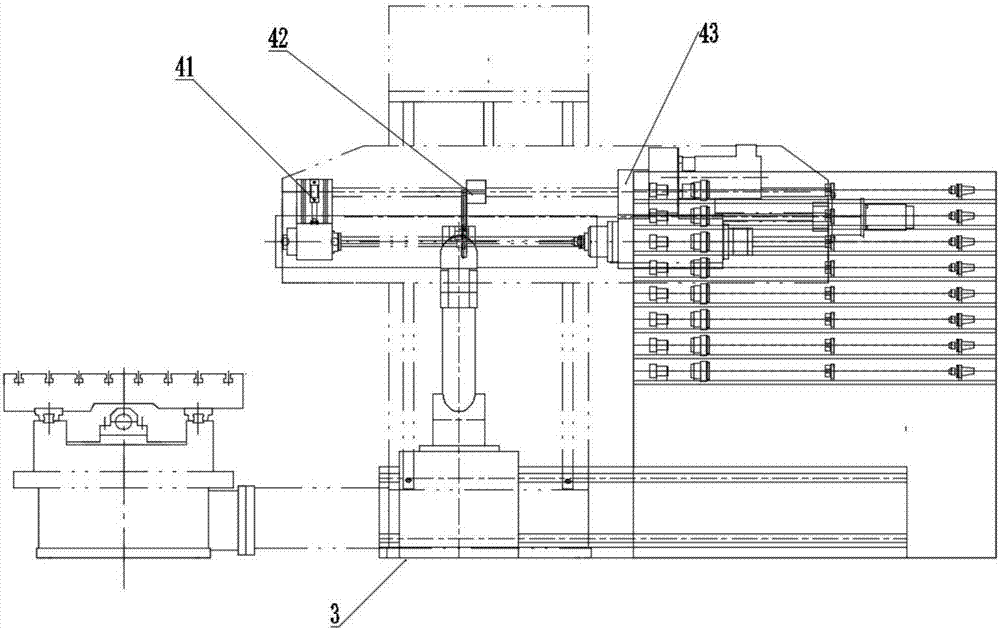

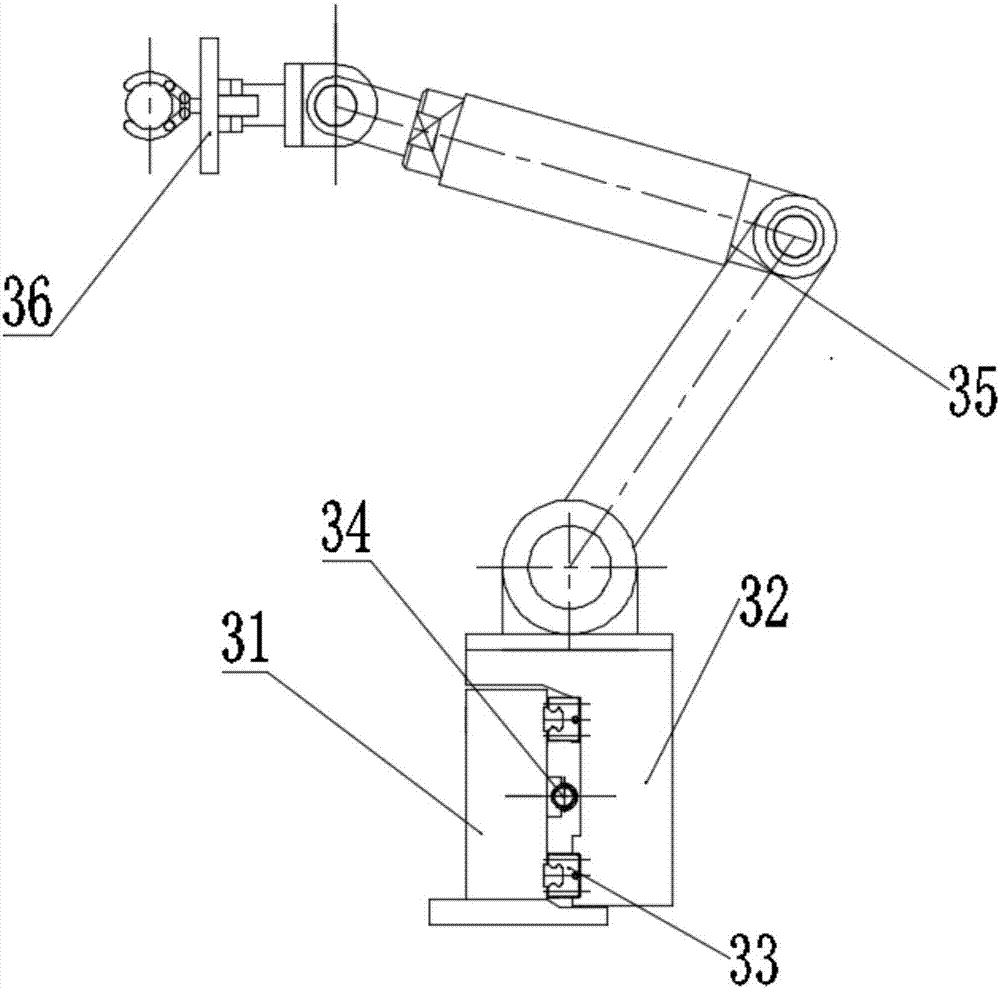

[0038] A deep hole drilling machine with automatic gun drill replacement of the present invention includes a machine tool 1, a slide plate 2 provided on the machine tool 1, and a replacement device 3. The slide plate 2 is provided with slide slide guides 4, preferably two, on the slide guide 4 The front guide box 41, the support frame 42, and the headstock 43 are arranged slidingly from left to right; the replacement device 3 can be installed on the floor beside the machine tool 1 or mounted on the top. The replacement device 3 includes a base 31, a sliding The seat 32, the guide rail 33, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com