Step chain same-side assembling method

An assembly method and chain technology, applied in the direction of metal chains, etc., can solve the problems of poor assembly accuracy and unsatisfactory passenger comfort, and achieve the effect of improving passenger comfort and assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

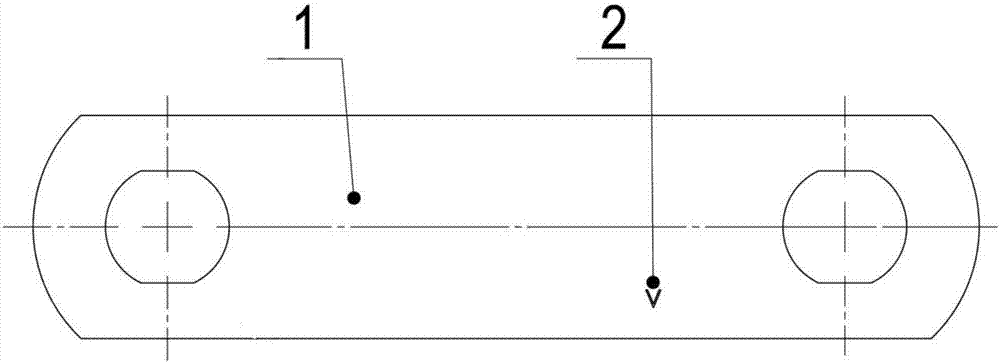

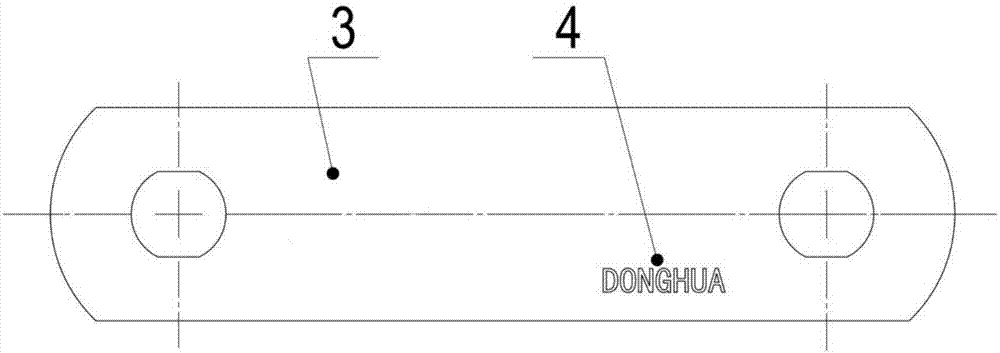

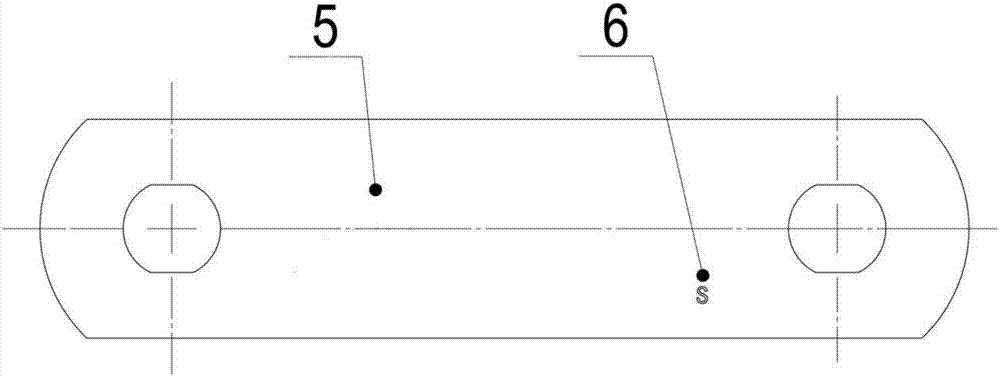

[0021] The step chain is composed of inner chain links, outer chain links, and step outer chain links, which are composed of multiple chain links connected in series by a hinge pair composed of a sleeve and a pin shaft or a sleeve and a step pin shaft. The manufacturing process of the stepped chain includes the chain plate blanking process, the chain link press-fitting process, and the chain assembly process. And the manufacturing process of required other parts on the step chain is no longer repeated in this description. The invention discloses a step chain same-side assembling method, which specifically includes a chain plate blanking process, a chain link press-fitting process and a chain assembling process. The chain plate blanki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com