Method and apparatus for evaluating an ultrasonic weld junction

A fusion line and ultrasonic technology, used in the generation of ultrasonic/sonic/infrasonic waves, the use of sonic/ultrasonic/infrasonic waves to analyze solids, and the use of sonic/ultrasonic/infrasonic waves for material analysis, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

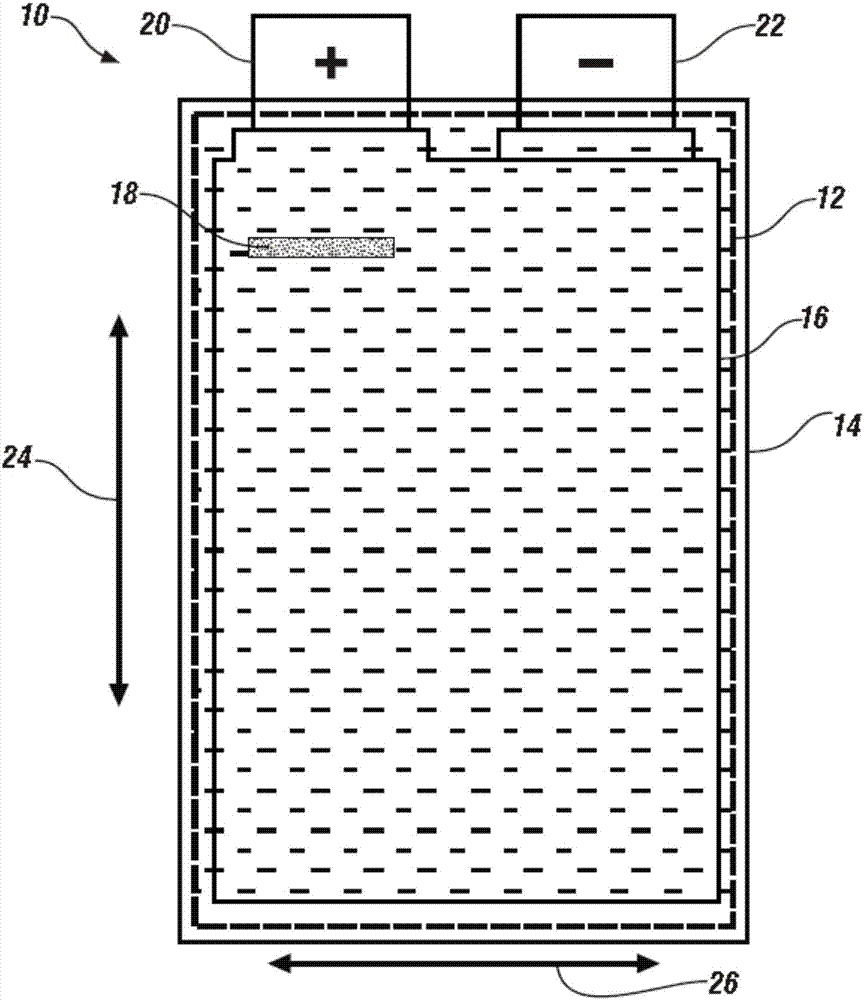

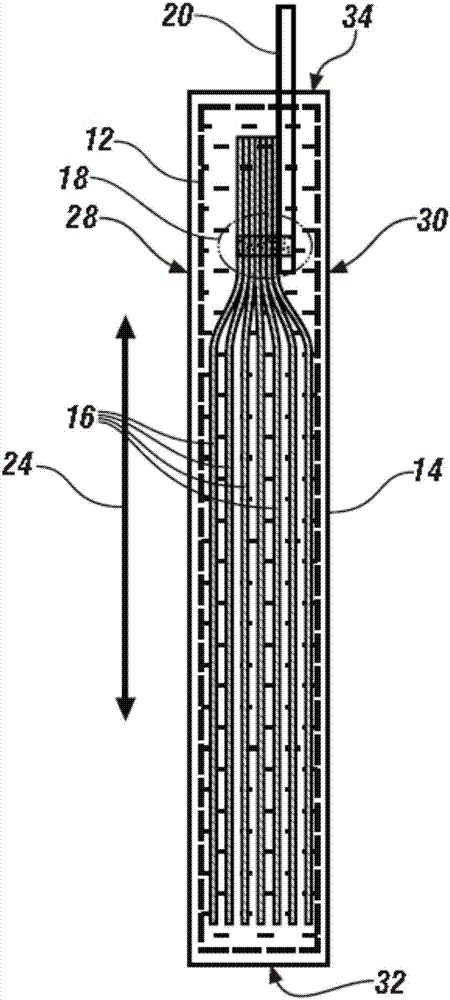

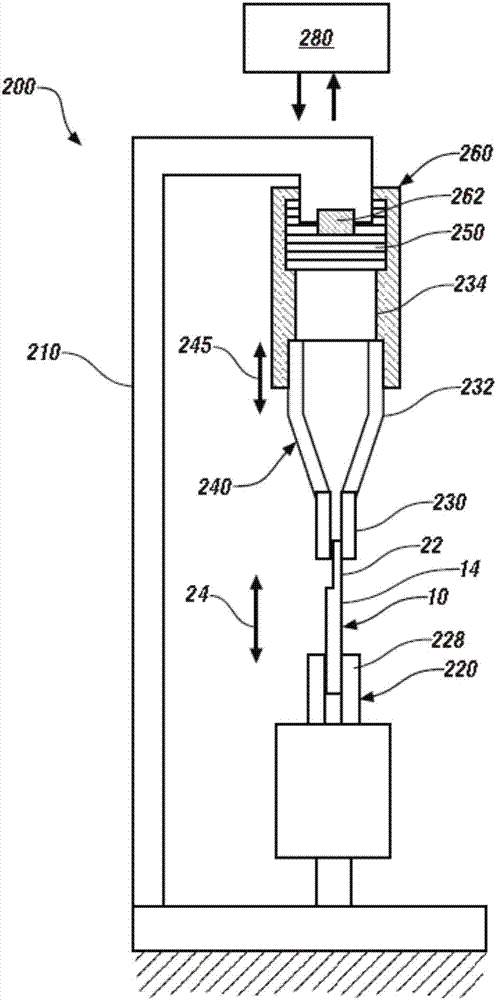

[0011] Referring now to the drawings (which are provided only to illustrate certain exemplary embodiments and not to limit these exemplary embodiments), Figure 1A and 1B A front view and a corresponding side view of a selection element of an individual battery cell 10 are each schematically shown. Like reference numerals designate like or corresponding components throughout the several views. Those of ordinary skill in the art will understand that terms such as "horizontal", "vertical", "above", "below", "upward", "downward", "top" and "bottom" The drawings are used descriptively and do not represent limitations on the scope of the invention as defined in the appended claims. The term "end effector" is defined as a device which can be controlled to perform a predetermined task in response to a control command, and which can also be actuated mechanically, electromechanically and pneumatically or can employ another actuation system.

[0012] In one embodiment, battery cell 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com