Automatic butt joint device for roving draught fan

A technology of automatic docking and fan, applied in textiles and papermaking, etc., can solve the problems of wear, shorten the service life, affect the use efficiency, etc., achieve the effect of small size, prolong the service life, and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

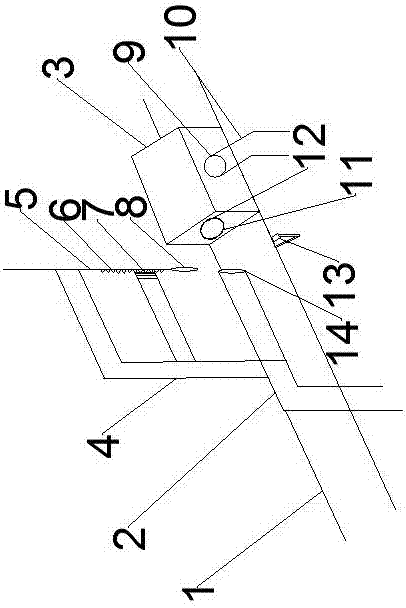

[0019] The structure of the automatic docking device of the roving fan of the present invention includes a track 1 , a moving fan 3 and a fixed air duct 2 . The mobile fan 3 is set on the track 1 for its operation, and the left and right sides of the mobile fan 3 are respectively provided with a "7"-shaped air intake pipe 10 connected to it through the miscellaneous inlet 9, and the mobile fan 3 is set facing the side of the fixed air duct 2 There is a socket 11; the fixed air duct 2 is set in the center of one end of the track 1, the suction port 14 of the fixed air duct 2 matches the position of the socket 11 of the mobile fan 3, and the upper part of the fixed air duct 2 is provided with an "F" type iron frame 4, The iron frame 4 is provided with a lifting rod 5, the bottom end of the lifting rod 5 is provided with a baffle plate 8, the bottom of the lifting rod 5 is provided with a buckle 6, and one end of the lower iron frame 4 is provided with an electric dial 7; A senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com