Displacement Tooling for Welding Longitudinal Seam of Steel Pipe Rod for Power Transmission and Transformation

A technology for power transmission and transformation steel pipe, longitudinal seam welding, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of continuous operation, affecting production efficiency, time-consuming operation, etc. , Improve welding efficiency and facilitate the effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

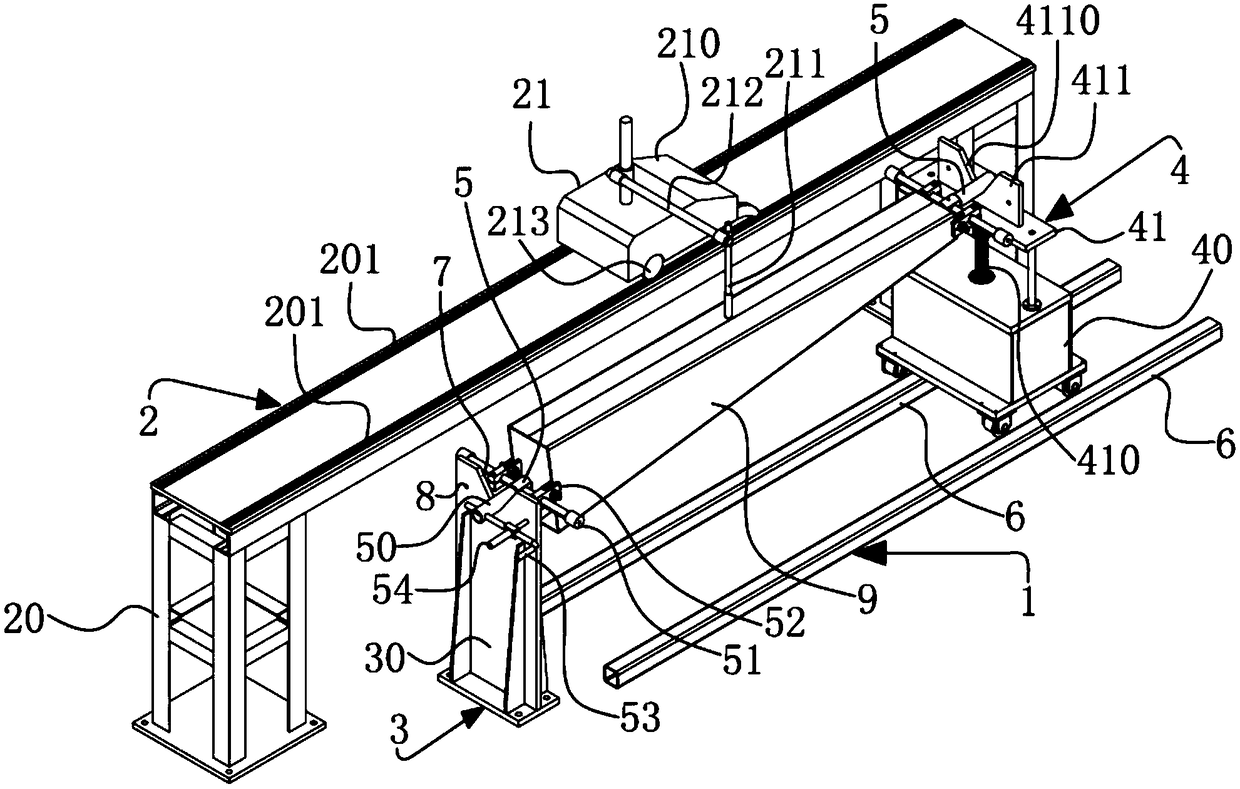

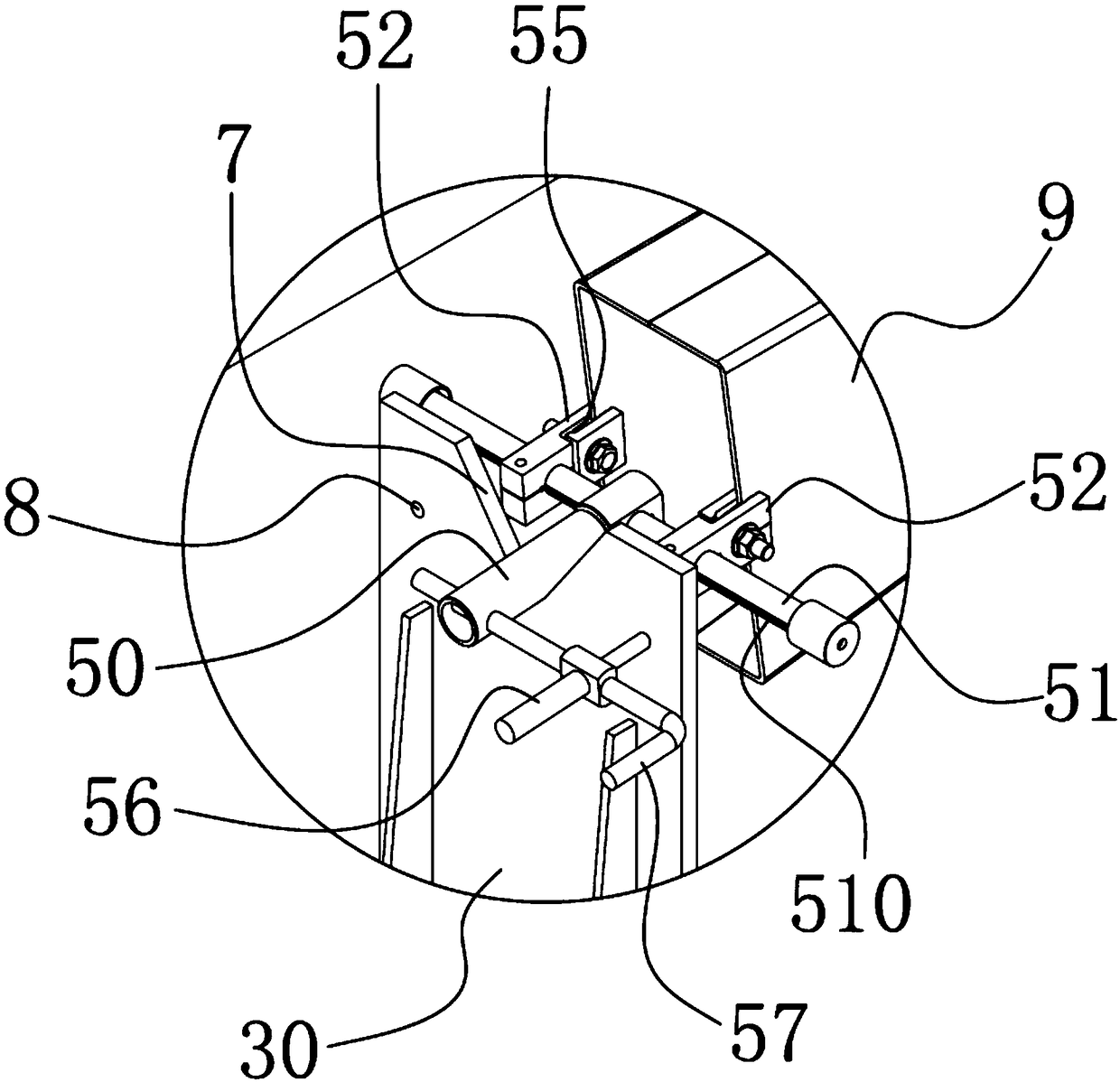

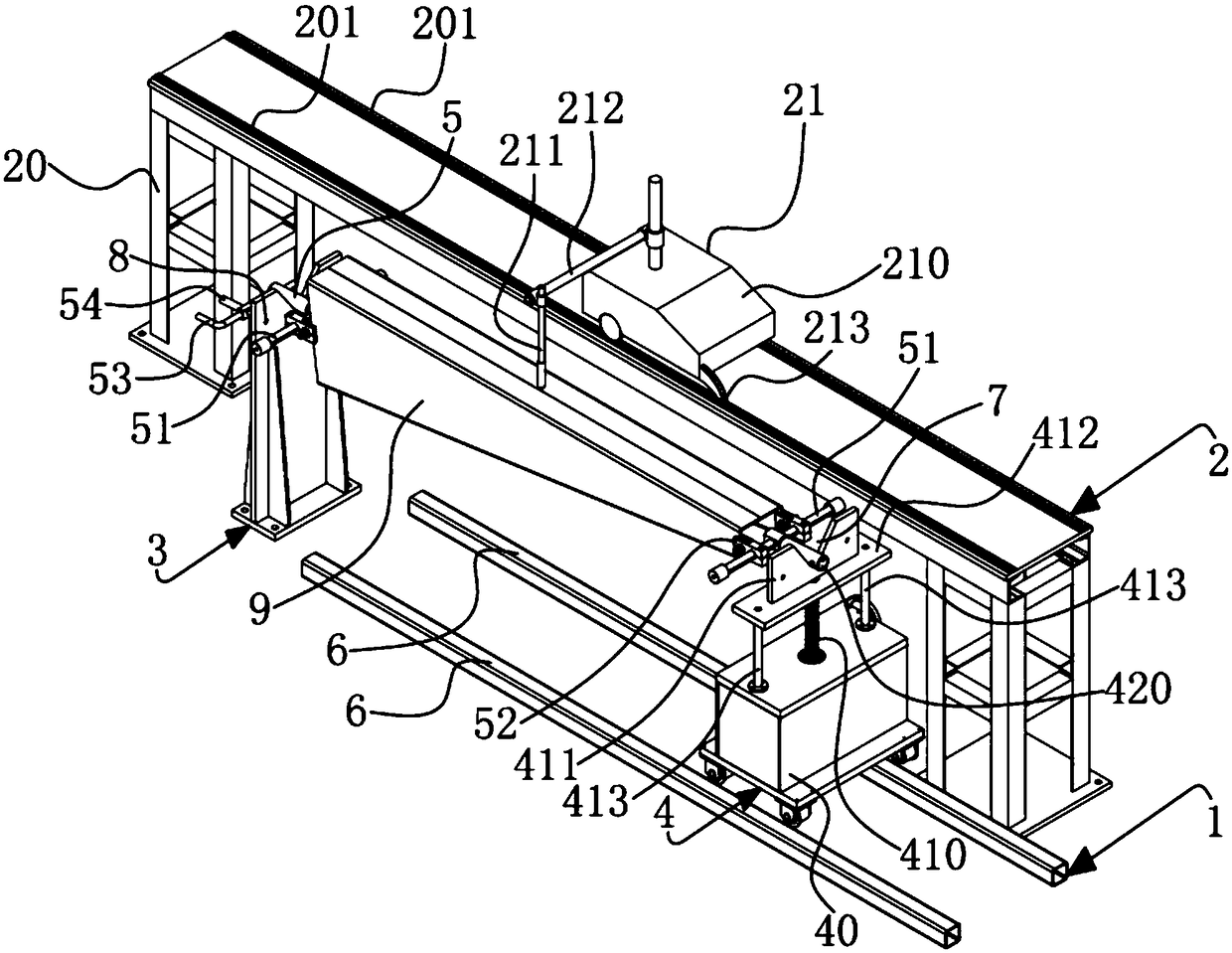

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0027] like figure 1 and figure 2 As shown, the welding displacement tool for the cross-arm longitudinal seam of the power transmission and transformation steel pipe pole of the present invention includes: a welding mechanism 2 and a fixing mechanism 1 cooperating with the welding mechanism 2 . Among them, the fixed mechanism 1 includes a movable support 4 and a fixed support 3; the movable support 4 is slidably installed on two parallel guide rails 6, and the fixed support 3 is fixedly installed on the ground; it can be understood that the fixed support 3 can also be fixedly installed on two guide rails 6, but is not limited thereto.

[0028] like figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com