Colander-type feeding device

A technology of a feeding device and a colander, which is applied in the field of cooking machines, can solve problems such as low degree of automation, and achieve the effects of improving the automation rate, ensuring the taste and quality, and meeting the requirements of necessary moisture and oil content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

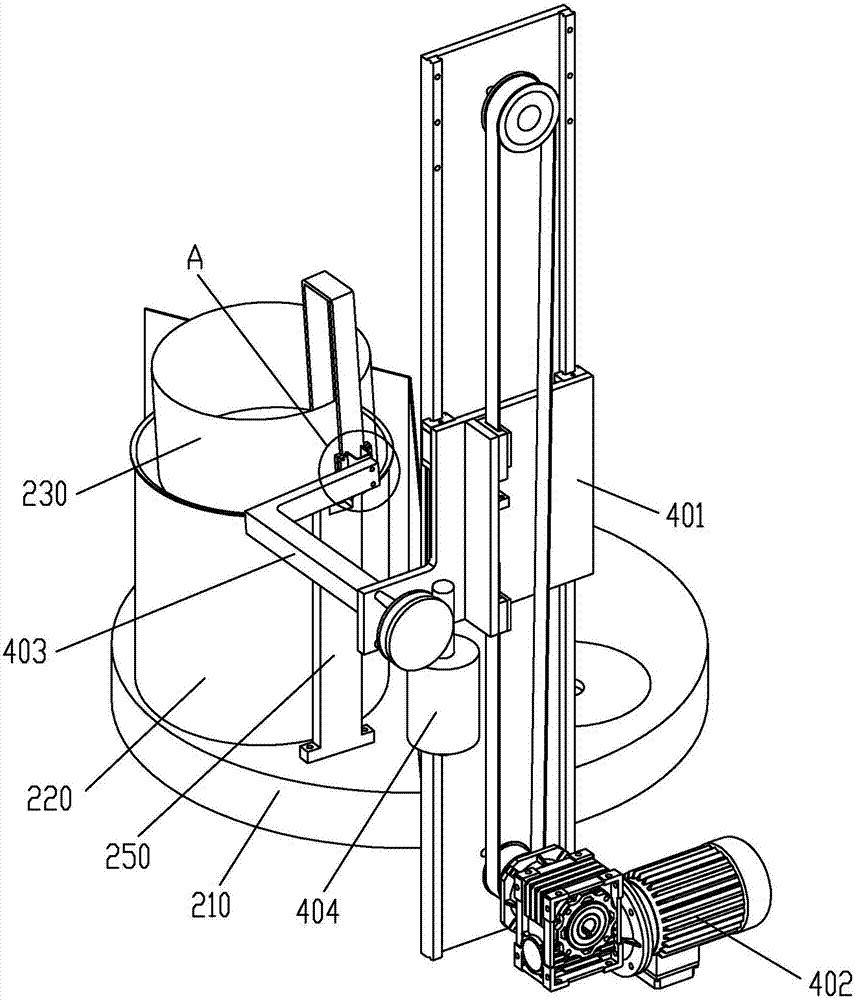

[0021] Example 1, see figure 1 , figure 2 , image 3 and Figure 4 , a colander type feeding device, comprising a colander 230 and a colander driving device, the colander 230 is placed in the material preparation cylinder 220, the material preparation cylinder 220 is arranged on the material preparation turntable 210, and the colander 230 forms a structure that can only be taken out from above through the colander positioning structure; The colander driving device is connected to the colander 230 through an elastic force coupling structure, and the colander driving device has a structure that lifts the colander 230 from the opening of the material storage tank 220 and turns over at least 90 degrees.

[0022] Wherein, the colander driving device includes a sliding table 401 set on the frame through a pair of guide rails. The sliding table 401 is driven to move by a sliding table lifting motor 402 through a synchronous belt transmission structure. The sliding table lifting mo...

Embodiment 2

[0023] Example 2, see Figure 5 , the spring clamp is composed of claws 407, and the two claws 407 are respectively fixedly connected to two claw arms 408, and the two claw arms 408 are hinged by hinge shafts 409, and there is a The loading spring 410 , the elastic force of the loading spring 410 drives the two claws 407 outward; the elastic clamp is connected with the connecting arm 403 through the transfer shaft 409 .

[0024] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0025]The colander driving device and the colander 230 in the foregoing embodiments are also connected through a magnetic coupling structure. The magnetic coupling includes two permanent magnets coupled to each other, the two permanent magnets are respectively arranged on the colander handle 230a and the connecting arm 403; when the connecting arm 403 moves to a set position, the connecting arm 403 forms a magnetic force with the colander...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com