Water-cooled easy-to-clean laser output head with function of output light path and light extraction power detection

A technology of optical power detection and output light, applied in lasers, laser parts, laser parts and other directions, can solve the problems of fiber jitter, affecting the stability of the output spot, breaking the fiber, etc., to enhance absorption, prevent complete damage, Easy to disassemble and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail in combination with examples and accompanying drawings.

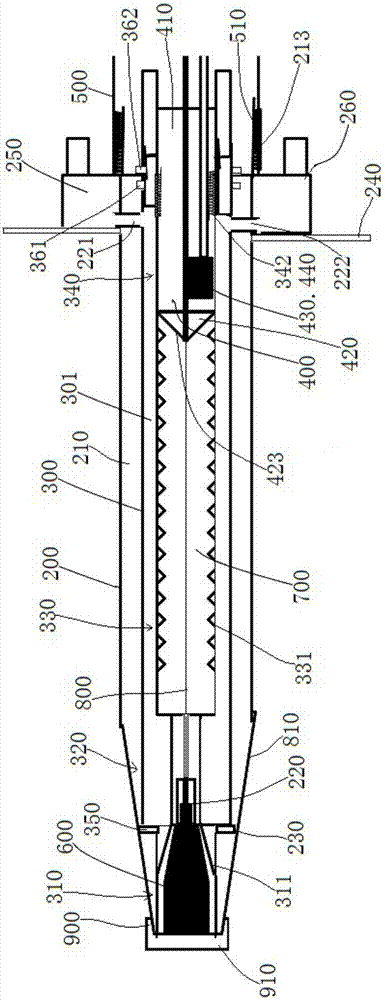

[0037] see figure 1, the water-cooled high-power fiber laser output head with output optical path and output light power detection function shown in the figure includes a metal outer sleeve 200 with a water inlet interface 221 and a water outlet interface 222, and a cooling water guide groove on the outer surface The metal inner sleeve 300, the detachable latch 400 and the tail pipe 500.

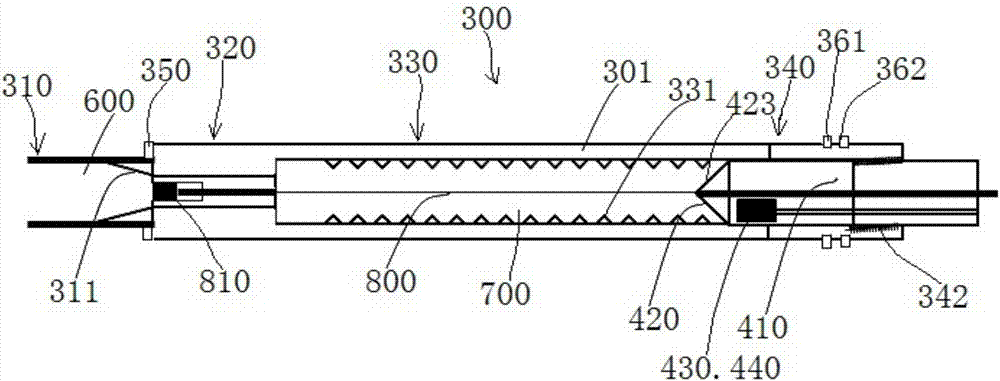

[0038] The water-cooled high-power fiber laser output head with the output optical path and light output power detection function of the present invention adopts a detachable structure, the metal inner sleeve 300 and the metal outer sleeve 200 are independent of each other, and the structural schematic diagram of the two being separated respectively by Figure 2 to Figure 5 shown.

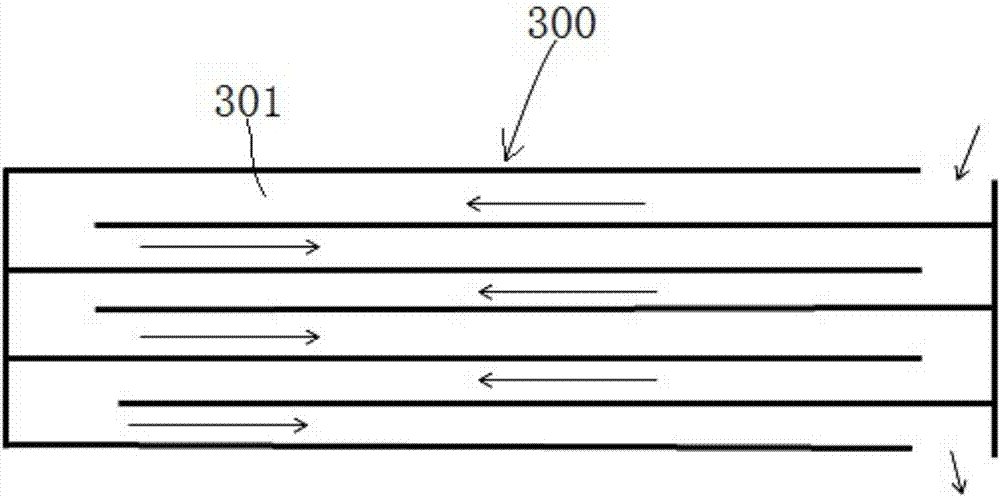

[0039] The metal inner sleeve 300 should be copper or aluminum with hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com