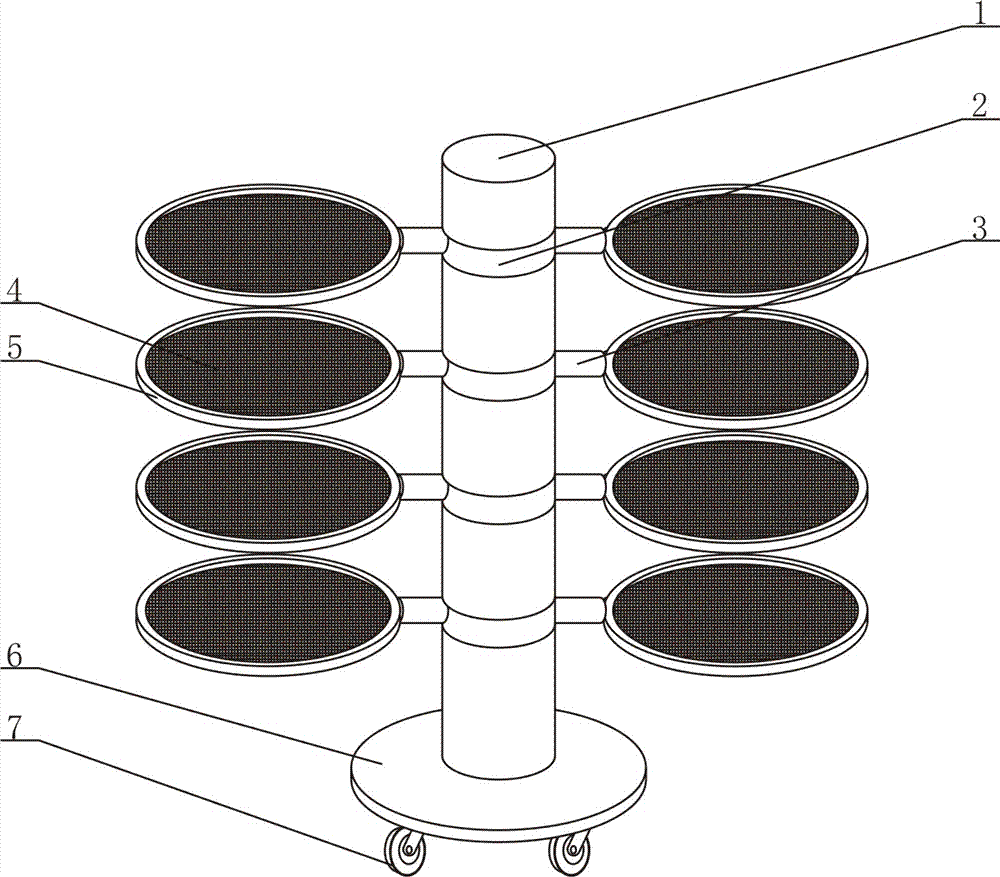

Feed drying rack

A drying rack and feed technology, applied in feed, dry solid materials, applications, etc., can solve the problems of difficult to find drying sites, reduce production efficiency, occupy a large area, etc., and achieve efficient drying, simple structure, convenient placement and collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

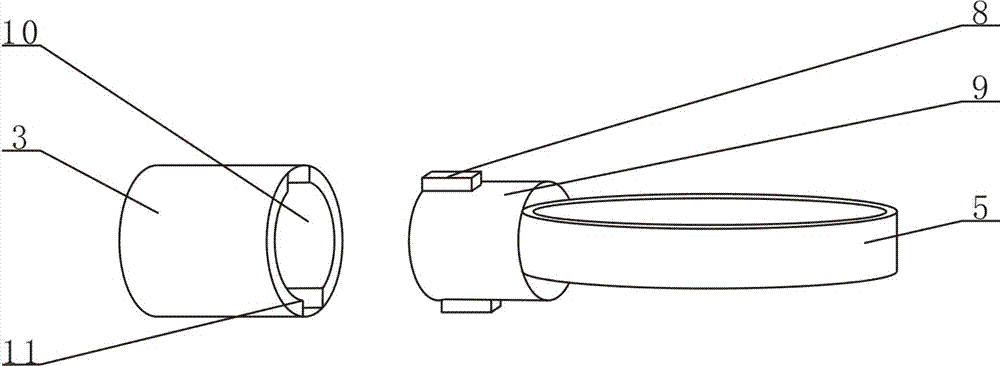

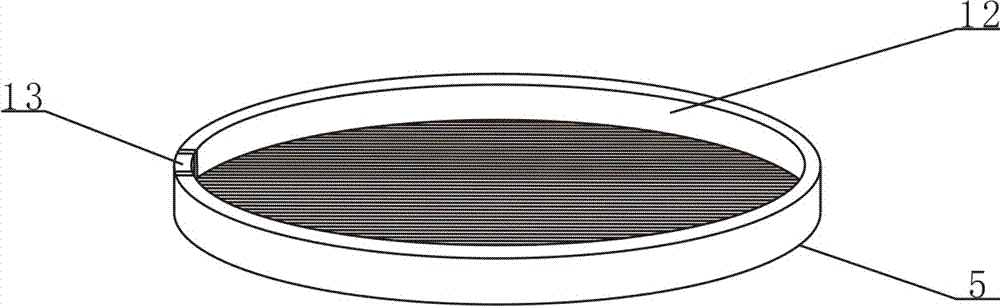

[0018] combined with Figure 1~3 The feed drying rack described includes a base 6, a column 1, a fixed sleeve 2, a casing 3 and a drying device, the bottom of the base 6 is provided with wheels 7, the upper wall of the base 6 is provided with a column 1, and the upper wall of the base 6 is provided with a column 1, and The front wall is provided with a groove, the groove of the column 1 is provided with a fixed sleeve 2, the side wall of the fixed sleeve 2 is provided with a sleeve 3, one end of the sleeve 3 is connected to the fixed sleeve 2, and the other end of the sleeve 3 A socket 10 is provided, and the socket 10 of the sleeve pipe 3 is connected with a drying device. The other end of the column 9 is provided with a tray 5, the bottom of the tray 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com